Hi guys,

usually CO2 laser machines are equipped with three mirrors. Do you think that fourth mirror would have a negative impact on laser beam efficiency?

Thanks for your comments in advance!

Another mirror would knock a few percent off the power and make alignment more complex.

What would it add?

I am dealing with a custom CO2 laser machine design and four mirrors would make the overall machine dimensions much smaller.

I’m going from memory on this so take it with a grain of salt but I think you can expect roughly 2-3% power loss for each mirror, even under relatively ideal conditions. Of course that’s going to depend on a lot of factors including mirror type but gives you an idea of what you’re dealing with.

What is your planned mirror configuration? Curious about the space savings.

If you’re going custom I’m almost wondering if you could simplify down to a 2 mirror solution.

Yeah yeah, two mirrors solution is also an option, just then the tube won’t be behind the machine frame, but next to the machine frame.

Usual solution is that portal is moving in Y direction, I’d like to have portal moving in X direction. So it leads basicaly to two solutions: either to two mirrors (which makes machine extra wide for tube length) or four mirrors (a few percents power loss).

What if you mount the tube to the gantry so it’s mobile?

Still going to take the same amount of mirrors, is it not?

Put the tube in vertically … over the machine or under…

I can’t think of an advantage in other configurations that isn’t already out there … Especially the tube riding around on the carriage. ![]() Glowforge like …?

Glowforge like …?

Maybe they can enlighten me…

![]()

I’m anticipating potentially eliminating traditional mirror 2. If the tube is mounted to the gantry you could have mirror 1 going directly to mirror 3 since distance between tube to mirror 3 doesn’t change. I’m speaking purely hypothetically. I’m not aware of this ever being done but conceptually I can’t see why it wouldn’t work.

As long as this is a custom system and if 4 mirrors are being considered, why not something else, especially if there’s an advantage.

I know Glowforge tube is gantry mounted but I’m not aware of the mirror configuration.

I’ve thought of this one too. Zero mirror system but would put a lot of mass on the laser head and would make wiring a little more difficult. But I guess not any more than a 3D printer other than the size of the vertical component.

I can picture this with the tube mounted in the Y direction… guess it’s an overload for me to imagine it like a glowforge, tube mounted in x direction but moving along y and losing a mirror… ?

I’d like to see the end product… or a concept drawing

Vertically – I was thinking of traditional mounting with it vertical in one of the corners with the conventional mirrors… so it didn’t move around…

I think I’ve decided the less stuff moving around, the less problems I have to deal with … still running with the KISS principle…

![]()

Ah… thought you meant along the Z. If I’m following you the disadvantage would be having the tube stick out the front or back.

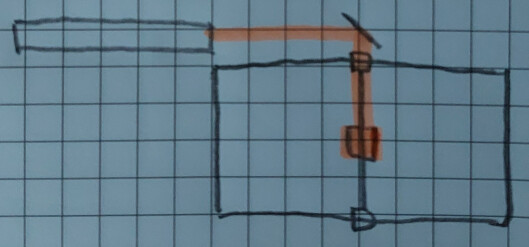

Here’s kind of a high-level conceptual view of what I was thinking for gantry mounted. A little impractical, perhaps.

Fist off I don’t think you can improve on the current design and second who is designing and building a custom machine these days?

I always thought gantry mounted tubes were for very large high powered units. I would imagine that they still have three mirrors anyway.

Not sure why Glowforge is doing it. Makes the desktop footprint smaller but it limits your wattage. I just wouldn’t want to deal with water lines and a high voltage cable moving around.

Drawing looks good, but there something queer in the concept of doing that I’m used to the 90 deg rule …

I notice Glowforge doesn’t do this, assume they don’t for a reason …

![]()

I think they’re fairly refined for the up-til-now market but new designs like Glowforge and Gweikecloud allow these lasers to penetrate markets that hadn’t really been tapped.

I suspect you’re right. The mirror alignment would still be potentially easier than traditional systems since there’s no travel on M2.

This is a fairly significant advantage. I think the other is that this allows the path of the laser to be entirely enclosed until it exits the lens. For a consumer device that’s a fairly big win. Remember the target audience is the same people using Cricut machines for crafts… not an industrial audience used to CNC or plasma cutters. These aren’t people used to necessarily risking their lives by operating their machines.

To me this is the major technical hurdle to overcome in the design. But really this only needs to be solved for along one axis and a fairly small set of requirements that need to be overcome. Maybe not the best design for industrial scale applications but acceptable trade-off for a consumer device.

No doubt. ![]()

I think there’s only marginal benefit getting away from 3 mirrors. Assuming Glowforge is using 3 mirrors it’s still relatively simple since M2 doesn’t need to move. I wouldn’t be surprised if they had M1 and M2 in a single structure guaranteed to be aligned. I like the idea of eliminating the power loss of one mirror but you also lose space due to the tube being mounted at an angle. That’s probably a worse tradeoff.

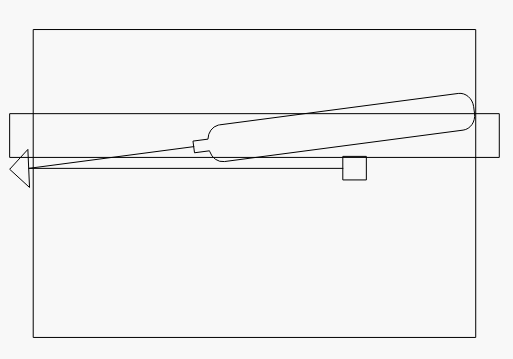

Well, this is “standard” solution with gantry moving in Y direction (top view with 3 mirrors):

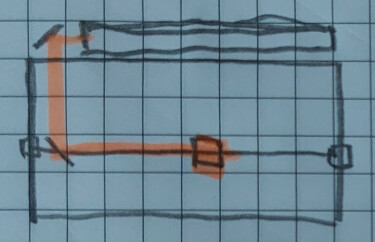

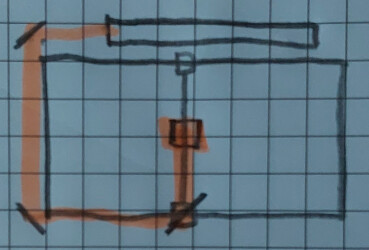

But I’d like to have gantry moving in X direction, thus I foresee one of those solutions:

either with 4 mirrors

or with just 2 mirrors

There is also an option to have solution with 3 mirrors, but in this case the laser tube shall be either totally vertical or sloping. But having tube vertical or sloping from top I do not want, because the first mirror would be quite significantly exposed to falling dust and fumes (due to gravity). And having tube vertical or sloping from bottom is impossible due to fixed heavy duty table to the wall.

I am still wondering if to save space and use 4 mirrors or to invest to larger frame structure and choose 2 mirrors option… ![]()

Are you saying that you couldn’t take the traditional 3-mirror design in the first picture and rotate the whole design counter clockwise 90 degrees and then increasing

I made 5 different lasers by now, different sizes, different purposes, different powers.

For what you are planing to use this machine?

Engraving and cutting plywood mostly.

The first picture, it is the best.

If you do like to make a double dimension machine than your material, as i have my machine now 1.5 meter X rail, the second it is the best.

The third, you need a much more space and a good machine frame, if you can do it, there will be no problem.

On the 2nd picture, usually the tube it is above the X rail, like that, you can load the machine from both sides, and put a lot bigger material through the machine. And the beam goes to Y, from the top, not from the bottom.

Regarding the third picture: machine is planned to be placed at the 45 cm thick wall and both laser tube carrier and machine frame will be fixed to that wall. So rigidity of laser tube and machine frame connection is pretty ensured (except earthquake). ![]()

So, the only extra space taken is cca 120 mm deep laser tube enclosure on the wall, which I am able to accept in 5x5 m large workshop. ![]()