Fiber and many other lasers types are pulse lasers.

With a fiber, the user specified frequency is how many pulses/s or pulses/mm.

At some point, frequency wise, the requested pulses/s will occur faster than the fiber has the time to fully pump up. This is the advantage of a higher wattage unit. A 100W fiber will fully pump up the fiber twice as fast as a 50W fiber. Allowing faster higher wattage pulses.

The drawback and why I have a 60W machine, is lenses go up in price about 8 times for 100W and greater fiber lenses. One of my lenses are about $60 US compared to about $480 US for a 100W or greater lens.

A MOPA (Master Oscillator Power Amplifier) will do anything a q-switched laser can, but allows the user to have some control over the pulse shape.

Q-switched (non MOPA) lasers have a limited frequency range and no control over the pulse duration (q-pulse width). Besides speed/power settings for a q-switch, a MOPA allows the user to chose a much wider range of frequencies and pick the type of pulse generated.

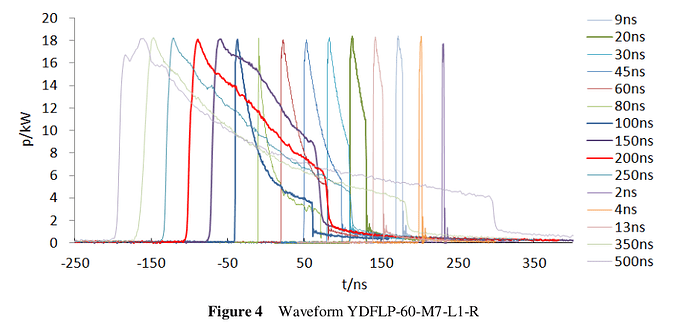

This is the output pulse shapes available with my JPT M7 MOPA.

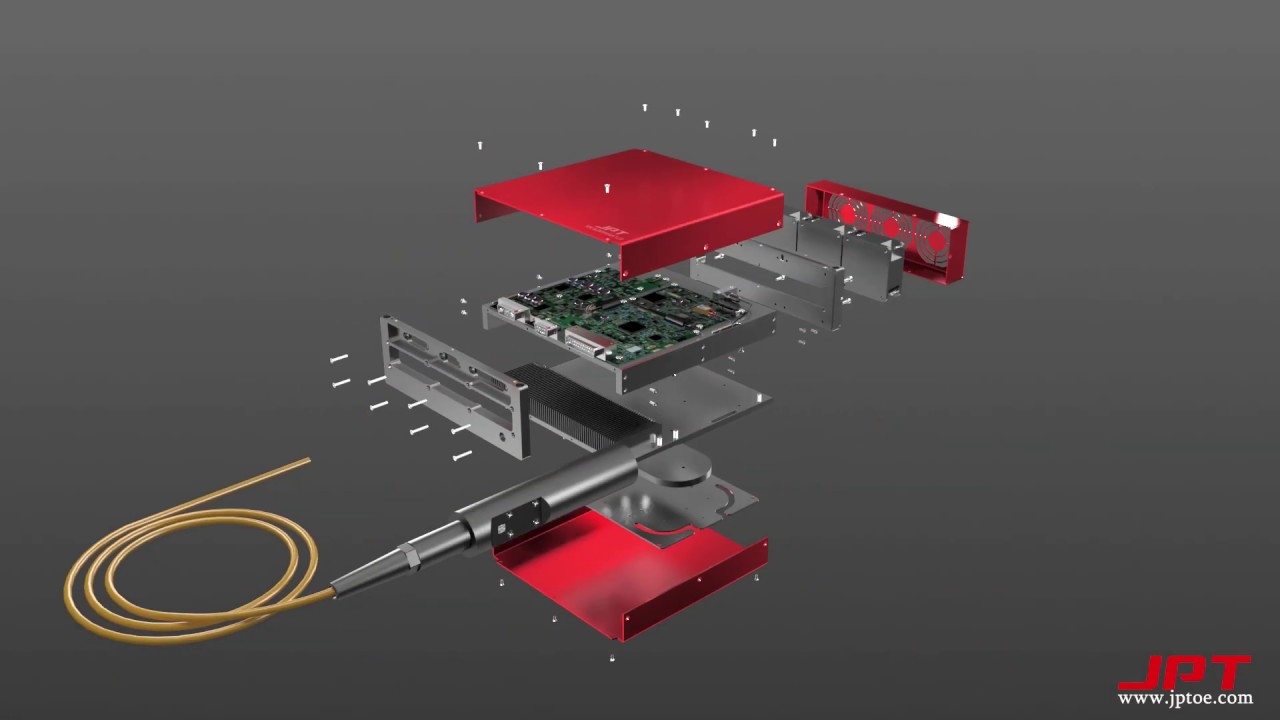

This JPT video gives a simple representation of how a MOPA fiber works.

I have spent lots of time trying to do color with my fiber. Simply put, you heat the metal surface, which oxidizes. This oxidation layer reflects some light and lets some pass through. As with any emf (electromagnetic field), the two fields produce many different frequencies such as adding them, subtracting them and many harmonics that also occur when mixing frequencies.

What we see is only the small area of visible light from this combination. This is how color is done. Changing the oxidation effect, causes a color change. Some marking will appear at only certain light angles others are visible from any angle.

Left is a stainless steel dog tag. You can see a great amount of variance with just a change of interval. On the right is a chunk of steel. Colors on regular steel seems pretty limited. You cannot feel any of these with your finger.

This chuck of steel leaves a nice mark, but you can feel it with your finger. Same piece, two angles.

Here’s a couple of links that might help you figure out what’s happening. They are not the most easy to wade through. But have some good thoughts on what’s happening. Don’t get too excited, some are done on picosecond lasers.

Formation of colours on SS304L stainless steel induced by laser colouring.

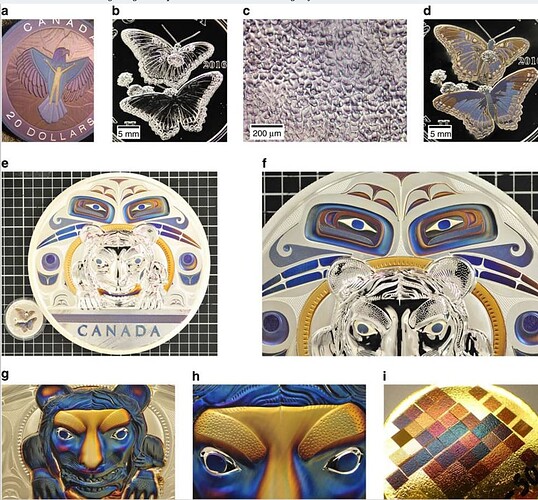

Laser-induced plasmonic colours on metals. Photo from this link.

IMHO, it’s a lot of work, you can’t easily transfer color information to a different type or size of the material or image.

As far do I need a MOPA, yes… don’t know about you.

I’d suggest and I would have gotten a lower powered MOPA over a higher power q-switch type.

My 60W does fine. I can heat up metals so much I destroy them or when doing 3dslice, I’ve sliced right through a brass 40mm coin. There is a limit of how much heat you can put into a certain size/type of metal before odd things, like color changes start to occur.

Probably forgot something and it’s also too long… sorry.