I will be able to make the longer tube work with rotary even if i have to turn it on its side.

What meniscus lens would you go with. Just for normal etching or cutting up to 5mm panels.

I have no clue.

Etching / engraving works best with a short focal length lens, cutting works better with a long lens. Your 2" would be a good compromise between them to start with especially if it’s a mixed engrave and cut project. Do the engraving layer with your air assist turned off and just the minimal bypass to keep the lens clear, and set your cut layer with air assist on and the best pressure you can get.

If you are buying lens’ specifically for engraving with your rotary, then I would suggest a 1.5". The HD will give you an even finer engrave, but you would not have a consistent enough surface with rotary work for that lens.

Hey Dave,

I have a 100w Thunder Nova 51 co2 and I’ve been cutting and engraving with the same laser head so far, using the included 2 inch head and 20mm lens. The thickest wood I’ve cut so far is 1/4 ply and the current set up does a fine job on that, albeit a little slowly. However, I would like to try cutting a 1" thick solid maple butcher block into an appropriately sized work desk, but I haven’t tried it yet because I’m skeptical of my current setups ability and I will only get 1 shot at the block, it wasn’t super cheap as you can imagine.

The air pump that came with my machine provides 5-7psi, not nearly the 15psi you recommend for MDF, which is the main type of board that I am currently cutting.

Do you have any suggestions on how to outfit this 100w machine for successful thicker hardwood cutting?

Also, my engraving efforts on this machine so far have resulted in a pretty low quality output, even when keeping air assist nearly off. I’ve had the machine for about 2 and a half months so I’m sure I just need to learn more about how to set things up.

I have a Dremel LC40 that is slow compared to the Thunder, but does a nice job of engraving. That said, the software is a disaster to work with. I’d love to do much more, at least 70% of my engraving on the Nova if possible but I’m not sure how to outfit if for that either.

Thunder sells a “Hi-Res Lens” option for around $400 but that seems way over priced to me, I’d rather figure out what I need and purchase from a company like cloudray or lightobject and get the parts at a reasonable cost. Please let me know if you have any suggestions, I really appreciate it.

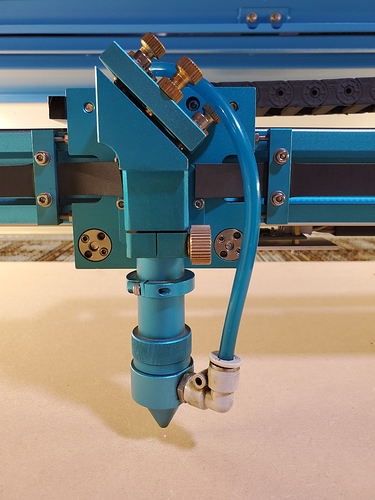

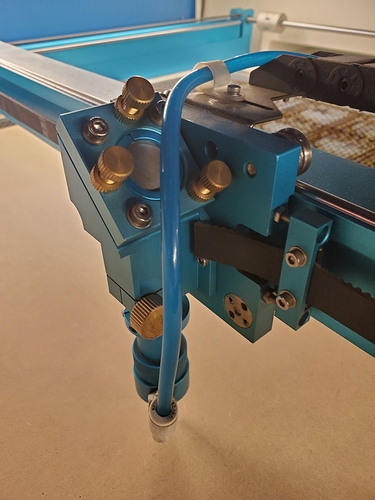

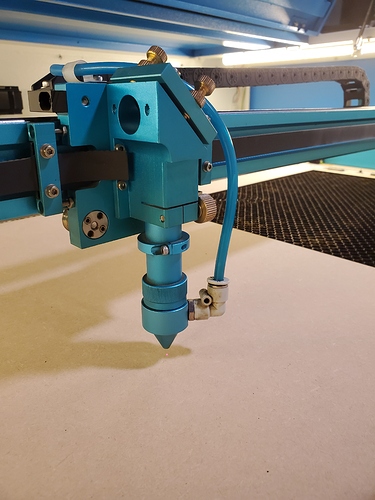

I’m attaching pics of the current laser head set up that came with the machine and the single lens that I own at this time. Regarding the nozzle head, the one on the left is the one I’ve been using so far. I haven’t tried the wider nozzle as of yet. Let me know what you guys think.

Thank you kindly,

DG in CA - Moleculeism

The two different nozzles have me a bit confused, and give me two avenues of thought to follow. The first being the one with the larger opening has a restricted air fitting making it an engraving nozzle. The second is the manufacturer chose to put a wide nozzle opening in to let you use a different focal length up off the work instead of putting a proper setup on it.

The next question is what is the outer diameter of the lower lens tube? Does it have threads to be able to put a lens further up the lens tube or at the top?

Cutting, especially thick materials, requires a LONG focal length and GOOD air assist. I wouldn’t even attempt it with anything less than a 4" lens and 15 psi flow pressure. If it’s not a pressing project, I would hold off. Russ is in the process of working out a long compound set up for cutting. If it works, it will take a long lens to narrow the beam to the center sweet spot of a shorter focal length lens giving you more concentrated power in a narrow cutting beam.

Engraving is speed and power and material dependent. And then you are also talking about what kind of engraving. Are you talking about vector engraving lines, shallow raster engraving for a decent color change, or deep raster engraving for maximum effect. If you are talking fine photo engraving then that is a whole new ballpark.

The thunder laser ‘Hi-Res’ set up by description is the same as Cloudray’s HD nozzle that Russ developed. That begs another question, what is your nozzle thread? Most everything you are going to get from Cloudray, LightObject, Alibaba, etc., will be an M22 nozzle thread. If you have a 20mm lens, your should have an M22 nozzle thread, you MIGHT have either a 24mm or a 25mm lower lens tube. If you do, you have many options.

Oh yeah, and a lightweight head from Russ and a new tube and nozzle from Cloudray will be half or less than the cost of that 'Hi-Res" thing.

I know it’s not a direct answer, but figuring this out will be a process.At least if you are in CA, LightObject is nearby for laser parts. Cloudray will have better prices, but longer shipping times. I’d check out any clearance sales for a small air compressor, and Harbor Freight and Northern Tool have some decent basic ones as well.

The Thunder laser hr head is completely different from Russ’s head. The Russ/Cloudray head stacks the 2 lenses one on top of the other in direct contact. This leads to overheating of the bottom lens and cracking. The Thunder head is manufactured with a sizable gap between lenses which eliminates the chance of lens damage. It is also a complete aluminum unit that slides in in place of the stock 2" head. There is no need to make an adapter. The maximum dpi of the Thunder HR head is 1954dpi. If you have any questions about the Thunder HR head, feel free to ask me as I am the manufacturer of that head, as well as the Beam Buddy HR head which is made for various laser brands on the market (We have one to fit just about any CO2 laser setup.)

I will stipulate that Russ’ setup stacks the lens’, and therefore could have overheating issues even with the air assist being fed below the bottom lens. I don’t own one, but I can see it happening in certain situations. But I will also have to say I can buy a lot of $8 lens’ for the cost of a $400 assembly. Even if I bumped up to a $15 or $18 lens, I would have to go through a lot of them to even get close to equaling the cost. If I was working them that hard, I’m sure I could give them a slight space to help with any overheating. Again, not a perfect solution, but I can buy a bag of O-rings for a buck and a half at the farm store.

But we are getting off point. Ronnie is trying to cut thicker materials at this point, not ultra fine photo engraving.engraving. If I was experimenting I would pick up the Russ / Cloudray tip and lens’ to start with. If I got to the point of doing a LOT of serious photo engraving, then i might look at justifying the cost of a $400 lens and nozzle assembly.

I would have to weigh the mass of a full size head and nozzle against his lightweight head for photo engraving as well. If I remember correctly, his lightweight head comes in at around 1/4" the weight. I know I was surprised at the difference when I installed it.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.