First time user of any CNC/Laser setup or Lightburn.

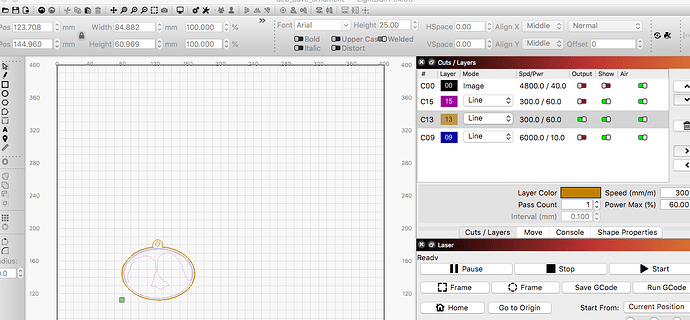

I have been gifted a Comgrow Z1 10w laser setup with a mecpow cutting table and air assist and filtration.

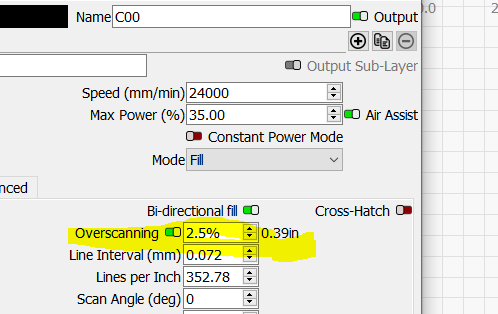

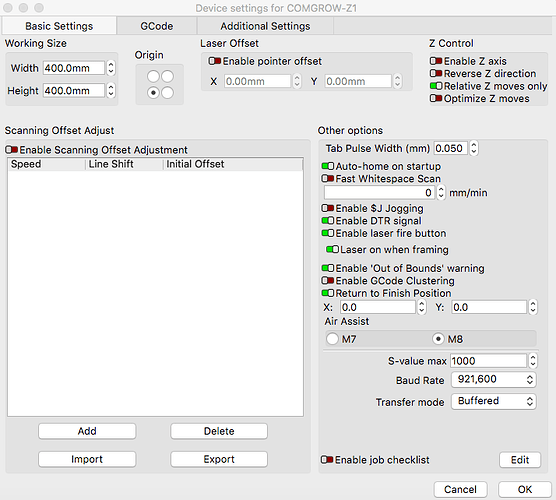

I have it setup and powered on and initially set the working size to 40mm x 40mm based on the markings on the side of the Comgrow profile and X Axis. I was able to do a successful etch of a provided stock image to a piece of wood yesterday but continued to get the " cut might be out of bounds " repeatedly despite reading and searching on how to resolve that, I was unsuccessful with that with Lighburn.

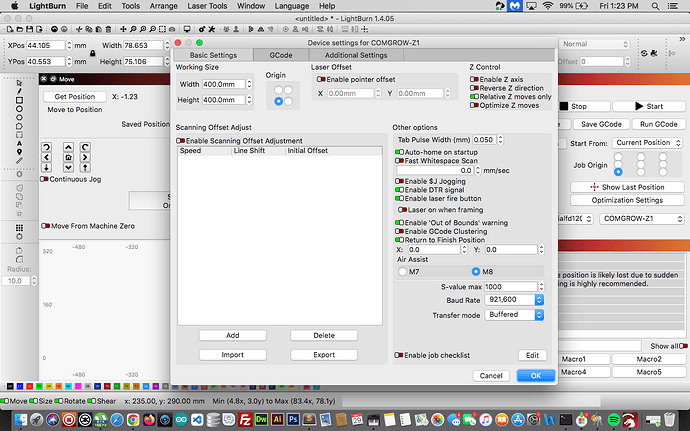

I’ve modified the working size to be 400mm x 400mm which is the correct dimensions based off of what Comgrow has listed in their marketing and sales writeup. Doing that, I assumed that would fix the out of bounds issue with Lightburn, it did not.

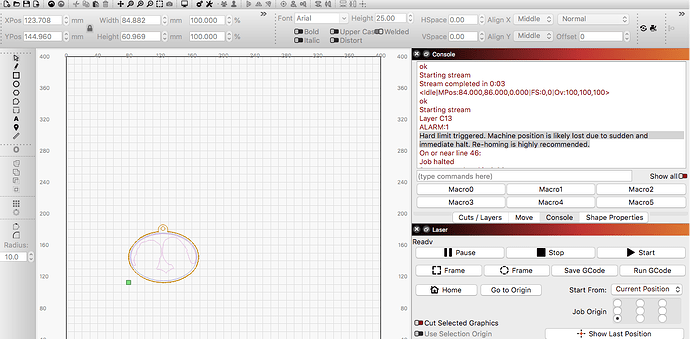

I then did another etch of a provided stock image and got the following error below along with the same " cut might be out of bounds " prior to going forward. I also framed out the dimensions before I went forward. The laser did not go off the material to be etched so I’m confused on that as well.

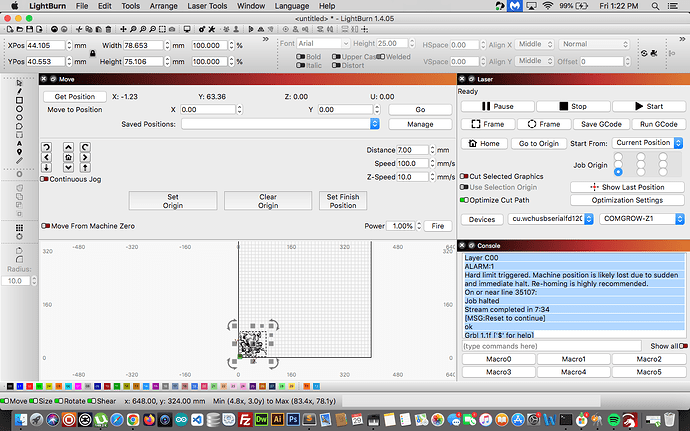

The second error occurred towards the end of the etching process, shown below

.

I honestly can’t make any sense of it ( granted I know this is a very long uphill process of learning something new here )

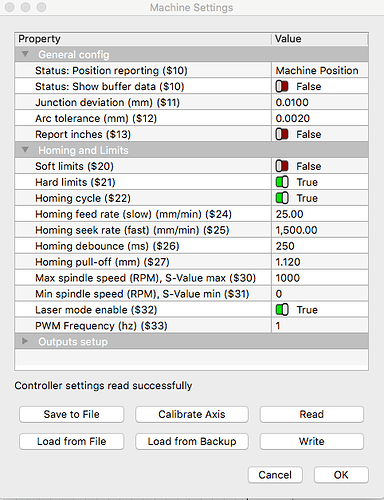

I do not see any physical limit switch being hit at all. The micro switch on the lower right side of the Comgrow unit isn’t triggered and the laser will home back when instructed to via the software. There wasn’t any faulty connection, I am using the provided USB cable and the connections are tight and not loose. Nothing lost power either, the unit just stopped and threw this error below.

Layer C00

ALARM:1

Hard limit triggered. Machine position is likely lost due to sudden and immediate halt. Re-homing is highly recommended.

On or near line 35107:

Job halted

Stream completed in 7:34

[MSG:Reset to continue]

ok

Grbl 1.1f ['$' for help]

The Mac Pro I am using is admittedly very old, it’s a 2010 High Sierra 10.13.6 with 16gb ram, I don’t think that would be an issue but if it is I have a 12 core xeon Mac Pro 5,1 with 128gb of ram I could try instead.

I am also using the trial of lightburn ( I have a license but did not want to use it just yet till I proved out the current Mac I have could handle it )

The version of Lightburn I am using is:

LightBurn 1.4.05, built Wed 2023-08-02 @ 15:08

Thanks for your time!