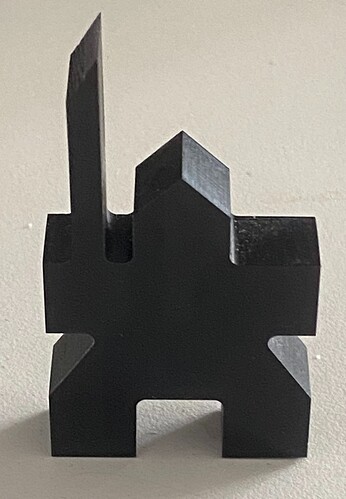

I am considering a more powerful laser than my 4.2W JTech diode laser. I may have a regular need to cut acrylic. One recent job was cutting 10mm thick black acrylic which I had cut using my CNC machine. (I have attached an image of the work piece). I had to produce several hundred at different sizes but all of the same pattern and in black acrylic.

I saw an advertisement for a Laser Tree item… using beam compression technology, about which I know nothing. Has any LightBurn user any experience with this company’s products or beam compression technology which seems to stack several low powered diode lasers together? In this case the company was using 6 x 5.5 Watt blue diode lasers for an output power of 30 Watts.

10mm thick black acrylic workpiece -