Hello.

I have an Omtech 80w red one laser with a PiBurn 4.0 rotary tool and using Lightburn.

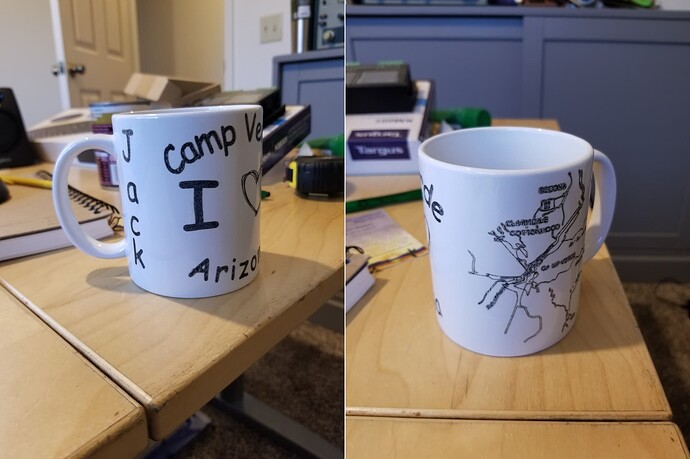

I’m trying to print a logo on both sides of a tumbler, but the rotary tool keeps rotating so that the handle crashes into the laser head.

I have followed the steps of this video ( https://www.youtube.com/watch?v=1BmRZohfyRo ) but seemingly, the frame always rotates around the topside so that the handle swings up and would hit the laser head.

The Roller Diameter and Steps of Rotation are set based on the manufacturer’s recommended settings - and I have properly measured my tumbler and image.

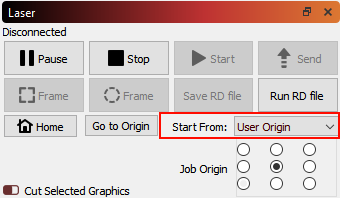

Is there a way to control the framing? Because I am unsure of the proper terminology, let me phrase my question another way: I would like to set my tumbler handle-down, tell the laser to turn counter-clockwise - print one side, then re-center, then turn clockwise and print the other side. Can anyone please help me find the settings to do this? I have just about hit every button or variable in the menus, searched up and down these forums and have still not found success.

Thank you in advance.