Hello,

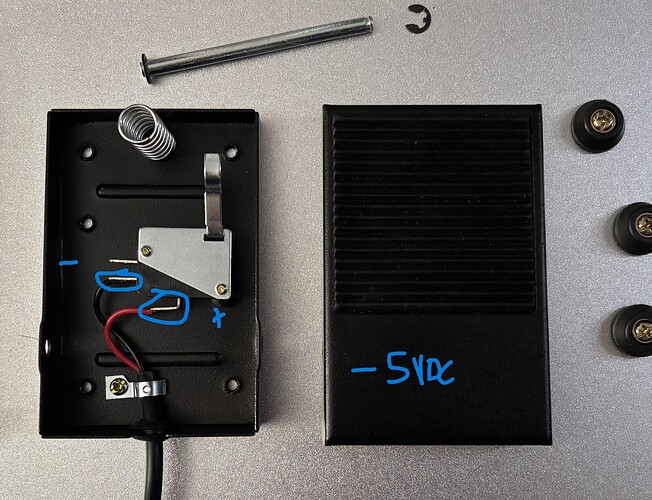

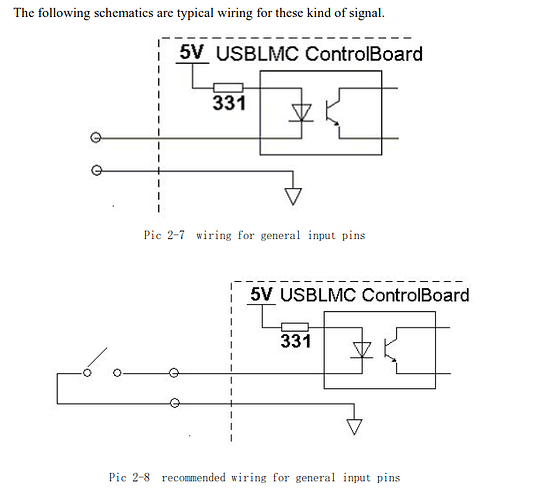

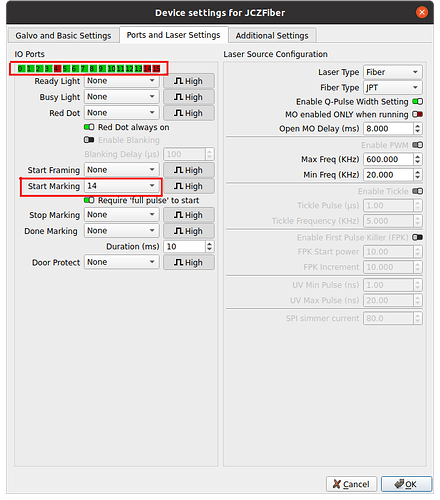

I’d like to have my laser’s exhaust fan relay be triggered to turn ON during jobs and turn OFF after. This should be straight forward, but I am unable to get Port 14 (Foot Pedal) to output. It is always -5VDC relative to ground even when configured for Ready Light, Busy Light, Start Marking, Red Dot, and anything else I thought made sense.

By programming “Ready Light” and other states to Port 14, I thought I would get a positive 5VDC signal on the foot pedal. I understand this is the opposite of what the IO was designed for, but if it’s truly IO, I should be able to make it the O part, not just the I.

I would like to repurpose the foot pedal as an output signal to trigger my exhaust fan relay when jobs are started and turn the relay off when the job is stopped. To me, this makes nothing but sense, but I am not able to output, just input.

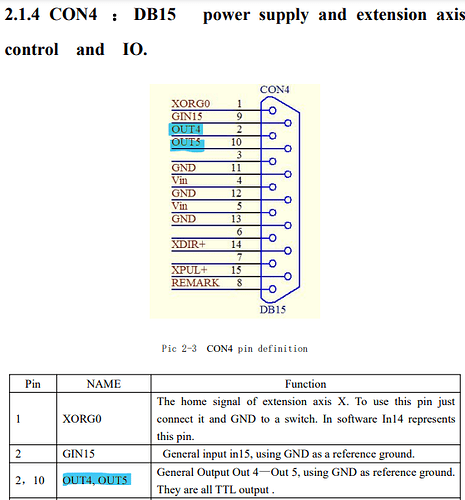

I understand my controller has OUT4 and OUT5 available, but I’d like to avoid soldering directly to the connector or make some other invasive hardware hacks. This solution made the most sense to me.

Can someone help me out with this? This is my first Galvo laser, so I don’t know everything.

Windows 11 PC

Lightburn 1.7.04

CloudRay MP-60 Fiber 60W JPT M7 MOPA

“Updated Controller” LMCV4-FIBER BJJCZ - Closest Manual I could find

Thank you.