I just want to relay my experience when upgrading the tube from 50w to 90w. At what I thought was a fairly medium power the new tube was able to destroy my existing gold coated glass first mirror in about a minute of cutting. Just shattered it. I have some gold over silicon coming which I hope will survive.

I hadn’t thought about the mirrors being a problem.

Are you sure your laser beam from the new tube does not hit the frame of your first mirror? If it hits the frame, it becomes hot and can cause the mirror to burst. Otherwise there are no special mirrors from 50 to 90 Watts, the classification goes up to 100 Watts by default, then comes another classification.

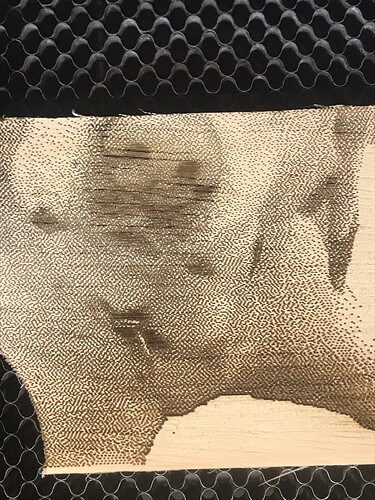

the beam didn’t hit anything as you can see from the attached. It just burnt right thru the gold/glass.

I don’t think this is anything that folks with larger wattage machines don’t know about. I just wanted to mention it because I couldn’t find much when I searched on ‘cracked laser mirrors’.

by the way I’m using my old power supply so I’m not getting 90w out of this tube.

Bummer! Two things to check, which probably you have done already, but doesn’t hurt to remind. First, this shows a lot of heat, make sure that the milliamps coming out of the laser tube on the return line is not over the maximum of the working milliamps for the tube. Most PSU’s have a pot that you can access to turn the milliamps up or down.

Second, the picture of the mirror at the top seems to show the top edge of the glass of the mirror with the gold coating under the glass. Mirrors for lasers are always “first surface”, meaning the coating should be the first thing the laser beam hits, not the glass. If the mirror was incorrectly installed at the factory originally, then there will be some refraction of the laser beam into unwanted areas and can cause heat where you don’t want it. Not saying that this is the case, just that from the picture it seems to be the second glass surface is facing outward. Now if it turns out we are looking at the “back” of the mirror assembly, than every thing I just said is bogus. Good Luck

Thanks all good points. I cracked two mirrors that day running 13 ma and the tube is rated to operate at 25ma. I did have one more old mirror and was able to complete the job by running at around 4.5ma. Meaning that same first mirror didn’t fail at a much lower power.

One site says that gold over glass mirrors are good up to 40W. So I think this failure is normal.

By the way on the same 60W power supply… old 50W tube barely cut a plywood at about 21ma. New 90W tube easily cuts same material at 4.5ma.

It’s surprising that I’m able to use the same 60W PS for tubes from 40 to 90W. You do have to stay below the tubes operating current

Most lps have a ‘response time’ in it has to reach 90% of it’s output voltage. The output voltages for higher wattage tubes must be larger to handle the physical larger tube size.

You might find that the response of the system isn’t quite up to what it should be. It would be hard to notice/detect.

The mirror looks like @rinconchuck advised, it’s on the wrong side. The only other time I’ve seen this is when the mirror is designed for a different frequency and it was literally melted/broke.

The gold is facing out.

Interesting about big tubes and response. I tried a little engraving at 300mm/s and it seemed to work. I’ll keep it in mind but not sure if anything can be done. Unless your implying that a bigger PS rated for this tube has a faster response? thanks.

Exactly what I’m implying.

The lps must generate a higher voltage for the ‘larger’ tube to start lasing, taking more time.

I have a China Blue 50 watt, it’s actually about 44 watts (880mm).

If I have interpreted the data right, my speed/dot tests have shown, that I have a very fast lps. Upon inspection, I have a 60 watt supply driving a 44 watt tube. I think a quick response would be expected.

If the response of the lps is sufficient for the original tube, it will not be as quick for a ‘larger’ replacement requiring higher voltage in the same amount of time…

Longer time to reach a higher voltage to lase.

At least that’s the logic I’m following.

Make sense?

![]()

Just to follow up on the tube response question… I don’t see any delay. Engraving is as good as my smaller 50w tube.

It might only be evident under certain circumstances of speed and dpi. If it was never what it should have been it may still be ‘not noticeable’.

The only real way is to measure it, which is a problem… Something I’ve got going on the side…

Don’t worry about it and have fun…