Hello, I’ve built a powder bot. A machine that prints powder (sand and mental powder) instead of plastic. It does this by picking up different powder dispensers of my own design.

The Z axis arm that grabs the powder dispensers has a Nema 17 stepper motor attached with a special adapter. It slides it place above the powder dispensers, connecting with the top of the powder dispensers. When this motor turns 90 degrees, powder begins to flow. It’s a gravity fed system so as soon as the motor turns back 90 degrees the powder stops coming out.

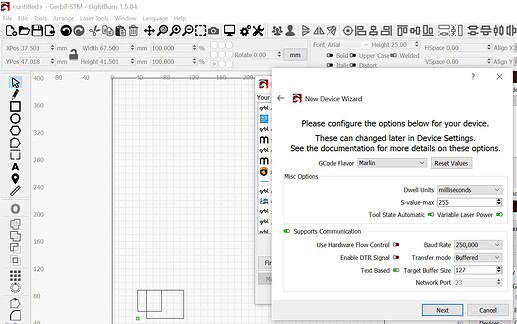

I’m seeking advice on how I can accommodate this behavior in Marlin. A traditional plastic printer would turn the extruder motor when plastic should be coming out and stop it to halt the plastic from flowing through the nozzle.

Is there a way in marlin to replace all the extruder gcode output with something custom? In my case, turn +90 degrees to start printing, then do nothing until it’s time to stop printing, then -90 degrees.

My partner and I have talked about the option of just parsing the gecode our selves after it’s compiled and replacing all extruder code with what’s needed but if there’s a way to do it with standard marlin, I would think that’s better.

Any advice would be greatly appreciated.

Thanks for your time.