I might want to order a custom size honey comb bed (50x104cm). Can anyone recommend a good and/or cheap supplier supplier, other then Cloudray?

Ha, thanks. What alternative do you use yourself?

Having watched a few videos … upon arrival of my machine I removed the honeycomb/aluminum supports and went to the steel supply. They had rolled sheet steel, so I had them cut me a piece that would fit the hole in the machine left by the honeycomb. Cost me $12 for the steel and ‘labor’ (cut).

When I cut things, I support them on 5mm magnets. Air flow draws the smoke directly out the back, usually in a stream. I also have to leave an inch opening in the hood or the air flow is pretty sad.

Any ‘goo’ left from the cut condenses on the steel and is easily wiped off with acetone or alcohol for acrylic. You eventually have to pitch the honeycomb as it’s difficult to clean after a while and it’s all flammable deposits. Cut lots of stuff and some of it is evident I was a little ‘hot’ on the power…

I don’t have a drag chain on the head, so no led pointer… Use jigs to hold parts.

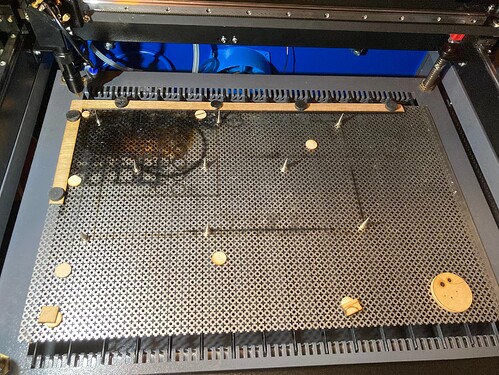

This is the replacement sheet. It is drilled for location holes used by my jigs to hole parts.

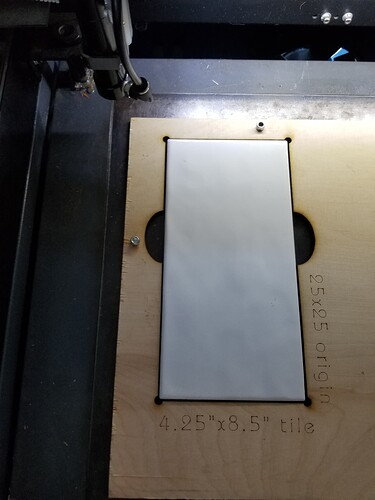

Jig for tile…

Slides into the ‘notch’ left by the honeycomb…

12"x12" mirror in a jig…

I’ve tried to find a use for the honeycomb, for lightweight parts or something. It seems pretty useless. I though I needed one when I began this adventure… I can’t bring myself to throw it out, but that’s coming…

Good luck

:smiley_cat

Thanks. That’s interesting. I’ll probably start with some self fabricated knife or pin bed. The steel plate is a smart idea as well. Especially with the magnets.

Thanks for the ideas.

No perspiration…

Good luck, take care…

I feel a bit the same way Jack, at first I wanted a honycomp bed, but after I got it it was discarded. Although mine is of good quality, relatively flat and made of iron and not of too thin aluminum, my perforated plate with my magnetic punk spikes is much more efficient regarding smoke transport and most importantly - I have very few brand marks on the back with this solution.

For large items, especially when many parts have to be made, I use the knife blade base.

The soot in the top corner comes from the tests I have done directly on the perforated plate or with only 3mm spacers. A cloth with alcohol, or acetone and the metal will be completely clean again.

I’ve been using honeycomb for many years and can point out some counter points.

I cut mostly wood and don’t spend any time worrying about how the smoke travels, as long as it exits the machine quickly. To be honest airflow from the nozzle is very important for cutting but the smoke fan just removes smoke.

The reason I prefer cutting on a honeycomb is that all the goo (wood resin) falls into the honeycomb for cleanup later. In other words it stores a lot, without messing up the back side of new parts.

It also reduces the blowback of stuff on the back of the part. All cut pieces stay on the bed and don’t drop thru, so it’s easy to keep track of parts.

I also find it light weight and will remain flat with minimal supports.

I don’t cut a great amounts so every few months I take it outside and soak it down with oven cleaner & water spray. Unfortunately anything that cuts wood resin is also hazardous to skin and lungs. I’m sure any part of your body. Which is far more important then how the smoke travels in the machine.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.