Ok folks. I know this topic has been covered hundreds of times but here goes.

When cutting circles, squares etc, the end points have a step.

IE, they don’t meet up using LB.

I have a 6090 Opus Laser 100w Ruida controller. The X/Y axis are at 90 degrees, belt tensions across the 3 belts “appear” to be of equal tension.

So annoying is this issue, i have decided to buy another laser with servo steppers at a huge cost!

So, I drove to Wales and Gloucester yesterday (from Southampton 10/07/23) to visit with Thunder laser and Trotec.

Our host at Thunder was fantastic, Wayne, the owner couldn’t have of been more helpful and accommodating.

Armed with a LB file on a memory stick, I aske Wayne if he could cut the flower shape on his Thunder laser 24 and 35 machines. I was hoping that this would prove, once and for all that our machine was the problem.

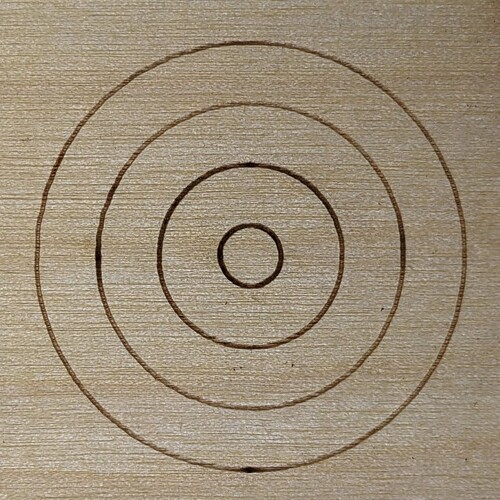

But…er…no! ![]()

The same issue was replicated on both the Thunder lasers, even tried on Wayne’s computers turning on and off “hide backlash.” Results were the same. Misaligned end points…!

So, maybe, I don’t need to plough 15k into a new machine I thought!

Wayne said that he uses RD Works and would try cutting the LB file though RD Works.

RD Works cut the circles perfectly. Endpoints married up with out any step at the end of the cut.

Amazed as much as I was, Wayne then tried again on LB, and guess what? Misaligned end points. Both of us were as perplexed as each other. Clearly, there is an inherent problem with LB software somewhere? I don’t buy it, that the “hide Backlash” option needs turning on, this is masking a LB issue, is it not?

So, we then went to Trotec, met with Jamie, again thumbs up to him, great guy. Tried out the R400 machine, (beautiful in every aspect, but to big for us), we tried our shape out on the machine, end points perfect, via the Ruby software that Trotec use.

I since contacted Aeon in Croydon to arrange a site visit to look at the Mira 9 laser, the sales chap has been amazing, asked me to send the LB file to them so they can look at the LB parameters and hopefully come out with an answer as to why the end points are misaligned using LB and not when using RD Works.

I have tried now, using RD Works to cut the shapes out on my machine, and the end points meet without any step on the circle cut out or the final shape cut out.

Tried LB and same results, end points misaligned…!

I am using LB Ver 1.3.01. I am loathed to spend any funding to “see” if newer versions eliminate the problem and I would ask for LB team to contact me with a proposal for ironing this problem out, not just for me, but for everyone who has a similar issue, because it is a serious issue, yet to be properly addressed by the LB team.

Sorry LB team, but this is so frustrating and costly, it needs sorting out once and for all, if every other suggestion has been exhausted, belts, X/Y alignment, laser beam alignment, bed level etc , then the issue must be at the door of the software.

I have proven, beyond doubt, its not my machine settings, nor Thunder Laser nor Trotec machines, its a software driven problem being somewhat “masked” by Hide backlash.

BTW, i love LB, hate RD Works, but what option do I/we have but to use RD.

I would encourage all other users to try RD Works, if they have the same issue and see if it replicates in RD and report back.

Really look forward to having a serious conversation with the dev engineers at LB and would welcome all valuable input.

As mentioned. all my machine mechanical parameters are set up as per all the YT channels

Belt tension…check

X/Y axis 90 degrees to each other…check

Laser alignment…check

Bed level with gantry…check

Free running linear bearings and rails…check

Stepper motor belt tension…check.

Thanks for reading my rant, hopefully it can be sorted out!