Ruida 6445G on a DIY 65x36" Laser and Lightburn

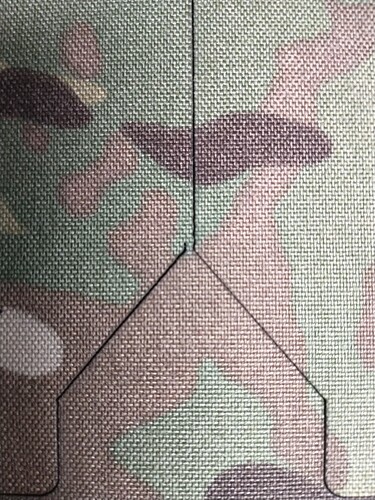

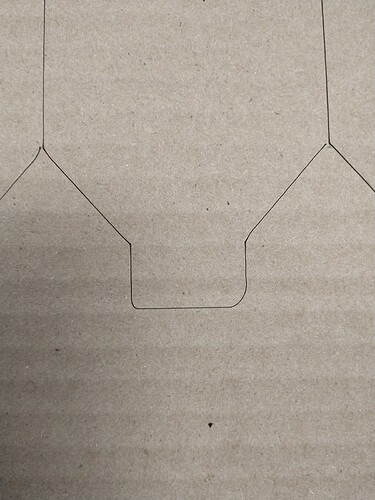

I recently had some issue with my laser and ended up doing a beam alignment, cleaning and belt tension. I am having issues with my cut line lining up and corner radius that are supposed to be .125" are sporadic. I thought maybe I got my belts to tight so I loosened them but I am still having the same issue and I am not sure if maybe this isnt a hardware issue and maybe something with controller? Or am i having a belt related issue on direction changes? I can cut the same pattern multiple times and get the issues in different places. The variance in the radius almost looks intentional and alternates sides per pattern.

Thank you.