I’ve had the machine for less than a year. Looks like I need to start investigating potential issues.

What is your MIN power setting? At 10 mm/sec a Ruida controller (by default) only uses Min Power. After 10 mm/sec, the power starts to ramp up toward Max Power. If you are cutting slow, you should set Min and Max power to the same value.

I usually set my minimum just a couple of percent lower than max. So If I’m setting to 60% power, I would set the minimum to about 58% or so. So my settings are 30mm/sec, 60% max power, and 58% min power.

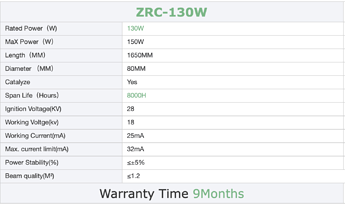

So maybe somebody can help me figure this out. I contacted the vendor of my laser tube. It is a ZRC-130. The vendor said it should be drawing about 6mA. That really has me concerned as I am drawing a lot more than that at 60% power. From day one the ammeter reads around 21-26mA. So my question is what control do I have over this? Seems it draws what it needs to draw. Though I have now cut thousands of projects, I still consider myself relatively new. Thanks all.

Obviously you would expect that it would cut thru 5mm ply at 21ma. The question is how low a power allows it to still cut that material.

Oddly you don’t determine laser power at high power but at what minimum power is needed to reliably cut your material. At some thickness minimum power and max power are the same.

You do have a problem if it won’t cut 5mm under 21ma.

Where did you get the 21mA number from if you don’t mind me asking? Just trying to figure all this out. Vendor says my laser runs on 6mA, yet it is drawing much more. Now you say it should be 21mA or lower.

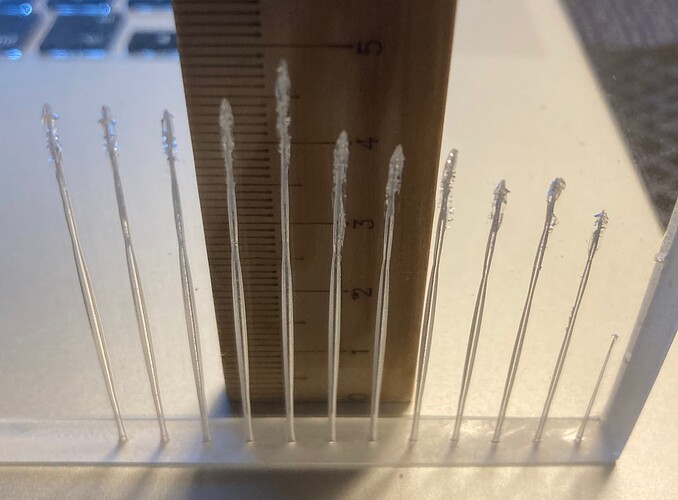

I ran a quick test. I was able to cut through the 5mm plywood with as little as 12 mA. So I need to adjust my settings a bit for cutting going forward. But my question is now, why would 60% power be drawing so much current? ~26mA

If it’s your laser tube then you have 25mA to deal with, it also fits well with you getting approx. 25mA at 60% LightBurn power.

From approx. 10-12 mA to 25mA it’s your working range, 0-100% and it’s not a straight line you need to do some proper tests to find your correct values. If you can not cut 5mm plywood with approx. 15 mA and a moderate speed, either your focus or mirrors are not in order or your tube / power supply is defective.

I have cut 15 and 20mm solid pine today with my 60 Watt machine, standard optics, 4.5mm / s and 65% -17mA.

Thank you. I don’t know where you got that screen shot of the laser tube I am using. I’ve been looking all over. Your google works better than mine.

Hi Nick. It sounds like you’re treating your CO2 tube well by drawing 26mA, but that depends on your tube specs.

My tube is made by RECI. The data sheet is here:

http://www.recilaser.com/en/uploads/soft/20200315/1584295042.pdf

Yours may be different, but I’m guessing they’re all pretty similar. I don’t know if your brand is RECI or not, but their W4 tube is 130W max, realistically 100W if you want it to live a long and happy life, 26mA recommended maximum driving current, 38mA actual maximum but at the expense of tube life.

Edit: Aaaaand there were a bunch of later posts my browser didn’t show me. I see Bernd already answered better than I did. Oops.

My tube isn’t RECI. It was supposed to be but the Chinese manufacturer did the old bait-n-switch on me. It is however rated at 130W normal operation and 150W Max. But I don’t know if I can believe the number for normal operation because when I set it to 60% power it draws as much as 28mA. So I imagine if I went to even 80% power it would be threatening the longevity of the tube. My takeaway is that I’m probably stuck at using 60% power as a maximum. Which to this point has been plenty for what I do. It just sucks to spend extra money on more power and not even get to use it really.

You should not feel too cheated by your supplier until you are aware of how many Watts you are getting at 26 mA. Your tube, I think can actually supply a nice part over 100 Watts without risking it dying. But to know it, it must be measured.

You can also do a test in acrylic, where you fire pulses by 1 sec and with an increase of 10 Watts. At some point you will see that penetration does not increase further, it will surprise me if it does not happen at approx. 70-75%. It’s your max effect. That is, all that comes after the deepest penetration is a waste of energy and shortening the life of your tube.

I have been able to test it on a 40, 50 and 60 Watt CO2 laser tube, but not on one as powerful as yours, but still I think “my theory” also fits on your tube.

Any pointers on how I would measure the wattage? I like your acrylic test idea too. How thick of acrylic do you think I would need?

After reading the post I need to put a milliamp meter on my machan but when I do, I’m going to find out i have a 50 wat machan.

That’s a good idea. If the CO2 laser power output was linear from 0-100, it could probably go with some reference values. But the curve is neither linear nor static in length.

Anyone use Lightburn with the Fox Alien 4040XE

Maybe you have solved this, I use a 150w Laguna with RUIDA controller. This machine won’t use the HIGH power setting unless you go faster than 10mm/s

I hope this helps someone. This info saved me.

Thanks, I am still waiting on laser to arrive maybe why taking so long to ship

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.