LE-4040 20w. I have the laser focused at 30mm. I am trying to cut out a very intricate design and am having some problems. On the very small parts it is burning more area than I would like. I am wondering recommended settings. Is it better to run lower power and more passes? Is 3mm too thick for my laser? What mm/m should I be running? Newbie here so any advice is appreciated.

I have found burning occurs when there is too much power in one location for too long a time so yes, I think either lower the power and more passes OR keel the power the same and speed up the cut.

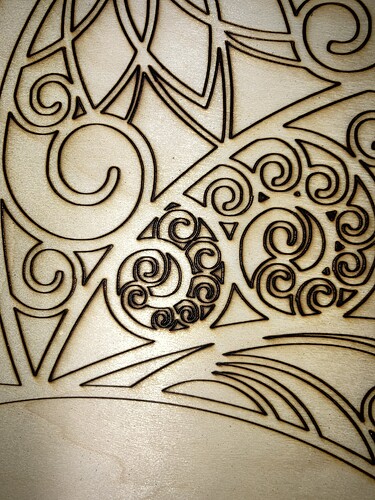

The pattern looks great though.

I have no experience with your particular laser so can’t comment further.

Good luck

Gary

Looks like at least part of the problem is you’re not fully focused. The beam on a diode is square and you can see that show up in some of the shapes on the top picture where the line goes from wide to extremely fine.

I’d start with getting your focus more dialed in.

I used the included positioning block to set the height to 30mm. Do you have a better method to fully focus the laser head? It is a fixed focus head so I am only able to focus it by adjusting the height. I also wondered about the laser head being perfectly square with the working surface. Do you have any tips for achieving that? Thanks for that info. I was also wondering why some lines appear extremely fine and some looked bad.

Hi Alex, is there more in focus on one side of the bed, or front to back…if there is and that happens each time, perhaps the relationship between your laser head and the bed (consequently material) is changing causing the focal point being great in some places and not in others.

Can you move the head to all four corners and half points, including center and measure the distance, head to bed.

If they are all the same within some reasonable degree of accuracy, cool. If not, make some adjustments. I don’t know your machine so can’t help.

Is your material flat, not warped so offering a changing terrain to the laser ?

Is the lens secure in the head ?

Try a focus test of some sort, there are dozens of examples in youtube. Then measure, every time before you start to burn.

So I just viewed your profile and googled LE4040 so maybe some of my comments are not so relevant but the frame may be twisted, even if new.

Let me know please

Great tips. You’re on to something with the height being different in different areas. I have noticed that on most of my work. The wood is a little warped but I have it taped to my spoil board to eliminate most of that. I will move head to different locations and measure. Thank you.

You could also try a “ramp test”, it is very easy and provides very valuable information about your laser. With diode lasers, it is an advantage to run the test in both the X and Y directions. (Mostly to see the difference of one’s square laser beam)

Thank you. I am currently on about my 5th pass on this project and am going to finish cutting this piece before adjusting frames and running test but that will definitely be my next step before cutting another pattern. Great info from all and much appreciated. I think between focusing, ramp test, and squaring up framing my issues will be mostly resolved. Thanks guys.

Without wanting to ruin the good mood, you should also be aware that diode lasers are primarily intended for engraving and not for cutting. I have been experimenting for a long time cutting in BB plywood with my diode laser without it looking like World War III. Poplar plywood works very well, but ordinary plywood is not so fine. Now I mostly drive with my small CO2 laser and even with it I can run into bad plywood which is impossible to cut through. Beware of dark layers in your material, it is most often outdoor glue with this color and it is very difficult to cut in. Buy “laser suitable” interior BB, then the chances are best to cut satisfactorily.

Yeah I knew that co2 was better for cutting when I purchased my diode for cutting. The price point was what mostly drove my decision. I plan to upgrade to a co2 machine in the near future. Just needed to make sure this was a hobby I really enjoyed before spending that kind of money. Thanks for the info though!!

If you enjoy always learning new stuff, and being creative, you’re in the right game

It sounds very familiar

I am so lucky that I have been able to sell some of my lamps and also get some order from a good craftsman friend (mostly in acrylic work) so my 2 lasers they are paid. But I will never get rich and I will not be with my hobby either. For me, it’s more meditation and I’m happy when I get something beautifully made. If the weather is bad and in the wintertime, I am in my small workshop and enjoying myself.

I see why you were able to sell a few lamps!! That looks absolutely amazing. How creative. I showed my wife and she said “how do I buy one” lol. The things you can do with these machines is amazing.

Greet your wife and tell her that I think she is smart and has taste.

I noticed my spoil board was resting on 2 control board bolts in the back. I cut away the parts of the board that were the problem and laser appears much better. Will try a few tests and cuts and see. Thank you guys

I use woodpeckers from Amazon for 1/8 or 3mm ply

Is it all going ok now

I assume that something has happened with the development of diode lasers in the last 2-3 years.

My 5.5 Watt diode could only handle 3mm with difficulty, but with too many turns and useless, burnt edges - this time.

It is exciting how long the new pumped diodes last, because even though the technology does not stand still, most of the 30 and 40 watt diodes that are sold today actually only have a maximum of 7.5 watts. I still do not think we can buy a 40 Watt laser diode for money in the consumer market.

I work in a different but linked field in the institute with Lidar as a navigational and targeting resourse, and oh my goodness the last 3 years has seen the advent of so much better, relaiable, cheaper, lighter units.

I love it

That’s fine to hear. What is the real output power of the new, most common diodes?