As a starting point - no. If you want to use the LightBurn power scale, you must adjust your high voltage power supply. I haven’t done it, but @jkwilborn will probably come up with a good explanation and help you with advice on adjusting the power supply if you want to do it.

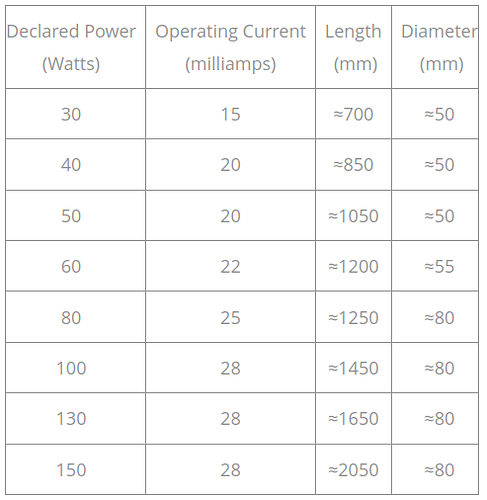

My OMT 60Watt machine, which is probably close to a 50-55Watt CO2 tube, I run with a maximum (rarely) 18mA and as standard no more than 16mA. This is what was recommended from OMT this time for my machine. I know these are pretty conservative limits, but so far I’m fine with it. Despite fairly intensive use of the laser for almost 2 years, only a minimal reduction in the power effect can be observed.

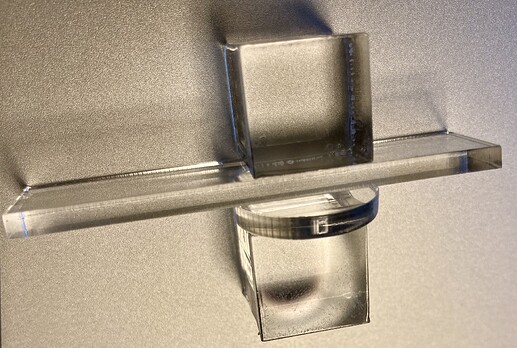

I can recommend doing a test where you find your tube’s maximum effect, you will be surprised. The test is that you use a thick piece of acrylic (15mm on a high edge, for example) and shoot with approx. 2-3 seconds a series where you increase power with e.g. 10% in LightBurn. I achieved my deepest penetration at 70% in LB, which corresponded exactly to 18mA. Then the result will actually be less deep again!

The values are, from left to right (in LB%), 5, 10,20, 30,40,50,60,70,80,75,85,90,95,100

To cut 15-16mm acrylic I used 18mA - 70%in LB and 2.5mm/s, 2X

For 8mm acrylic my values are, 6.5mm/s at 10mA - 40% in LB, 1X

note, the square is 3x3mm