Hello

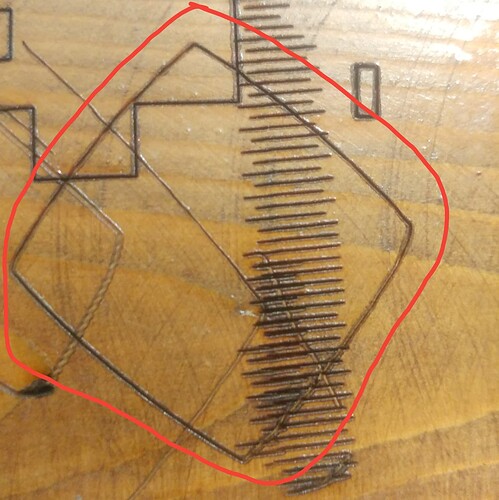

I’m using board mks dlc32 with latest firmware and core XY version but my problem is that the circle that laser cuts is not a clear circle

how can I fix this issue?

The problem with CoreXY machines is that they’re prone to backlash and lost motion unless their long belts and hardware are perfectly tensioned and extremely well maintained.

Basically, you must go through every part from the motor mounts through the pulleys and belts to the laser head, looking for anything that can move under tension, belts with a tiny bit of slack, or anchors that allow a little motion, and eliminating all the problems you find.

If those circles are 10 mm in diameter, you’re looking for motion on the order of half a millimeter, which will be easy to overlook.

Congratulations on getting it to work, because those things are hard to build! The next step will be just as difficult, but when you’re done it will be just about perfect …

thank you for your help bro

but I think It is lightburn software issue because previous version(1.0.04) when I draw circle in lightburn and start the process my laser cuts square instead of circle and when I updated lightburn the circle is like the photo that I sent

this is the result when I draw circle in version(1.0.04) and start process

Hello,

i made a homemade machine to but for cutting steel . If you have a look on your round shape they are actually fine from 0 to 180 degrees and from 180 to 360 . the problem is the transition of the motor of you axe y . ( i think ) . the motor as to go from forward to backward and it take too much time . so you end with this . ( i personnaly got a flat on both edge ) . I had better result by changing the microstepping and upgrade the nema motor from the nema 17 to the 23 . do another test and stay focus on the Y motor, you ll notice ( i believe ) a delay . you may be able to play a bit with the acceleration on the gcode of you Y axe . good luck . Florian

I also built my own machine… well several now. lol, but my Co2 laser build was having issues with flat edges on circles. Each quadrant was chopped equally off. I pulled the whole machine apart and checked all my steppers and belts and bearings and everything I could think of. I mentioned my issue to my friend @Colin and he suggested strongly to upgrade my laser control software from the China LaserCAD that came with my AWC dsp to try Lightburn. Lo and behold that was the issue… Lightburn basically made my laser awesome. Any issues I have had since have been minor adjustments to bearing tension. I over-tightened a couple and had weird shaped circles… I immediately adjusted them and was cutting perfectly again

Ho,

that is intersting . i kind of give up to cut round shape.

I m a fabricator so i am cutting the part slightly bigger and fix it with the grinder ( not ideal ) .

so yeah i need to check this out . what is interting is that i made a Pikachu ![]() the curve are actually fine . But as long as it s a full round shape it turn to a disaster

the curve are actually fine . But as long as it s a full round shape it turn to a disaster ![]()

I need to have a look on the software maybe to adjust . or any other thing which could help .

I actually use a design of a machine and print the part with a 3d printer . it s nothing premade . so i am putting that on the limite of the machine itself .

so instead of an answer i m bringing a problem ![]()

( i m aware that the quality isn t great but it s much better than having to start from nothing with a grinder

thanks

Flo

thank you for your reply bro

Do you know why I insistence on lightburn software issue bro? because the corexy chassis that I use for laser before It was a 3D printer,actually I changed my 3D printer to a laser by changing motherboard and remove z axis,when It was a 3D printer there was no problem about printing the circle things,the circle 3D printed things where very clear circle but now that it is a laser,it has this problem about circle while I didn’t change any thing about X and Y axis

Can you upload the following:

- .lbrn file of the circle

- push File->Save gcode, then save with .txt. extension and post file here for review

Those files look fine to me. That implies either a mechanical issue or motion control issue. I haven’t seen anyone else using a Core XY version of the firmware for MKS DLC32.

Have you run other tests to confirm the mechanical fitness of your machine? Your original photos looks like you have uneven belt tension. The second photo with the rounded square shape looks more like a motion control issue but hard to say.

Some things to check for:

- if you burn a large square, is the burn square and dimensionally accurate

- if you burn a square with a larger line interval like 1mm, are the lines parallel and consistent and accurate; repeat for horizontal and vertical lines

- For the rounded square shape, does any dimension match the original circle? Which one?

yes bro burn square dimensionally accurate and

the lines parallel and consistent and accurate

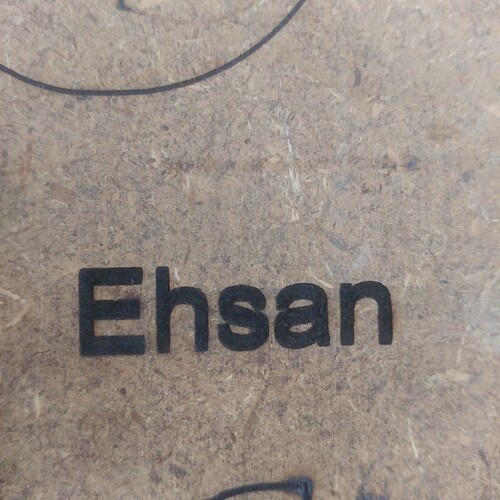

this my laser engraving

my problem is just with circle

Don’t rely on complex shapes. Create some test patterns to confirm function. You want to try to minimize the number of variables being tested for to be able to narrow root cause.

Why do these letters look so bold? Does this match the source?

it may sound silly but the head of the 3d printer and the head of a laser doesn t have a big difference of weight which may bring more strain to the motor ? again, i don t know much about laser. But i had the round shape issue because of the size of the motor on my axis .

good luck

Florian

That text doesn’t look right to me. Especially the “s” and “a”.

The laser will have much higher acceleration than your printer. The mass of your print head will not be as much as a factor while printing as its speed is limited to the speed of the extruder. Also the laser has overshoot past the part and a deceleration time as it reverses. I would try and tune the laser for slower acceleration and deceleration times to compensate. If your motor drivers can handle it you could also try a slightly higher current setting to give the steppers a bit better holding torque. Braking and takeoff will be tighter.

looks a bit like what I’d call CO2 laser, nozzle bounce.

Definitely thicker in one dimension.

Here is my engraving laser on metal

i said my only problem is with the circle! and I’m almost sure It is lightburn issue according to what I said about the Previous version(1.0.04)issue which I had installed

See my new engraving bro please

Not sure what to do with that. You’re focusing on the tests that seem to validate your preconceived notions rather than trying disprove other hypotheses or that would otherwise help you narrow in on root cause.

If you recall, we already validated the gcode which looks fine so that leaves only the controller or the mechanics. That means LightBurn is not the root cause. You could confirm this by running in LaserGRBL or something similar if you want to confirm. However, make sure it’s a like for like test in that case.

One big difference in what you’re seeing is that you’re comparing scanning operations vs cutting operations. Those stress the mechanics in different ways. An issue with one may not be obviously apparent in the other.

What firmware are you using on that controller? The manufacturer provided one are terrible and riddled with bugs that rarely get fixed. I converted mine over to fluidnc. Much better success but still had controller issues with incorrect geometries. Converted the laser to use standard grbl controller and no issues at all.

Have you tried a standard grbl controller? Not grblesp32 pref using standard 8 bit Atmel hardware as that is very proven. Yes limited in I/O and processing speed but you should still be able to test this buying cheap hardware for bout the price of a cup of coffee.