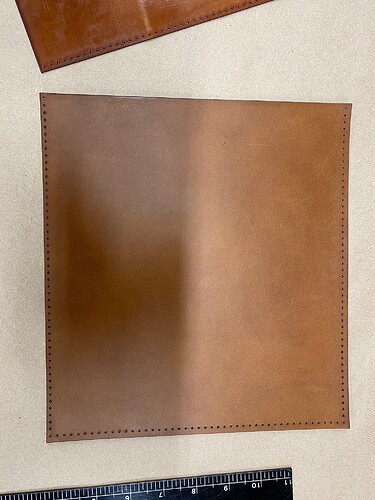

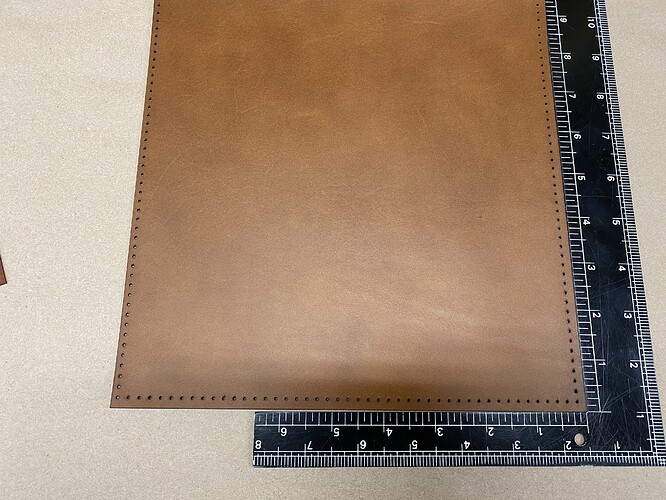

Hello, please help! I cut leather wallet patterns with stitching holes. I was working on a portfolio and one of my pockets did not align to the inner layer. The cut is a rectangle and it is not quite perpendicular. If I put a square edge ruler to corner, you can see that one side is not quite straight (perpendicular). I’ve cut piece vertically and horizontally with no change. I’ve checked mirror alignment and its perfect. I’m thinking its a setting in lightburn but not sure which one?

Thanks!

Mike

It sounds like your machine is out of alignment and you need to square up your gantry.

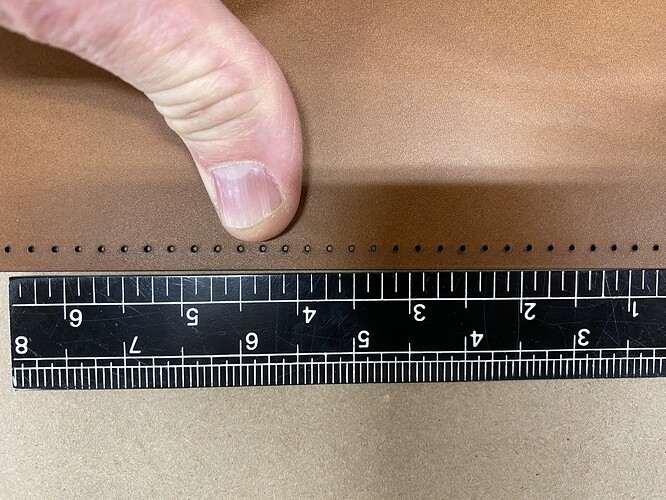

I just checked machine alignment and gantry with level. any recommendations on process to check gantry? I used level. It seems to be same side of piece no matter how I position leather, which is odd? I did have similar problem before but with alignment of stitching holes along a line… the fix was to turn off PWM rising edge. I don’t remember which axis was turned on (as one side was on and one off) but i turned it off and fixed my issue. I checked and both axis have PWM rising edge turned off still. Would this be a possible issue? I will say that i usually do not cut these big of pieces (12 inch by 9 inch) but all of the pieces cut perfect except this last one.

I just cut 4 pieces at different angle in the machine. Its the same side that is slightly off on each piece. the holes seem to be aligned correctly with the line but as you can see in image… not quite perpendicular. The side that is off is the last side that got cut each time. I cut holes then cut entire piece

Is the material pulling / contracting when being cut? Are you holding it down? If you can cut wood or paper without misalignment, it’s probably the material itself.

I’ve been cutting same leather and holes on machine. I always use same leather (hold with magnets) and hole size and speed and power setting with no trouble until now. I haven’t done that many portfolios (bigger than what I normally cut) as I normally cut pieces for wallets. This is my 5th time cutting out pieces of this size and never had this problem before.

WEll… In the process of checking machine settings I now have a bigger problem. Now, My ruida shows x and y axis at 10000mm for both. when i start machine, laser bangs edges (trying to get to home on 10000mm work area I’m assuming). In lightburn, my x and y are still as they should be (600mm by 400mm). Any thoughts on how to remedy this? I did change several parameters but changed them back (x,y acceleration max). I do not have a settings backup file and I cannot seem to change it manually from key pad on machine.

Thanks!

Mike

I’m currently working with vendor to restore machine to original settings. Regarding my original problem (lines not straight/perpendicular)… I’ve been reading a lot on this forum and I’ve seen some posts regarding “phantom line/double ghost line”. I do have that in addition to lines not perfectly straight. My beam is hitting the mirror on laser in middle in all postitions. However, I cut leather with my machine and it can get a bit dirty. My question… Could dirty lens cause lines to not be perpendicular and cause phantom lines? Could this be same problem? I’ll have to wait until my machine is up and running to test on clean lenses but thought I would ask.

Thanks!

It’s possible, yes - Gunk on the lens can cause the beam to scatter more. It can also absorb heat and cause the lens to crack too, so be careful if you’re using dirty lenses.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.