Have you accounted for the width of the cut in your adjustments?

Assuming you have a 50 W laser (because of the name and Ruida controller), the kerf in plywood (and most materials) will be about 0.2 mm wide. If you calibrated the step distance using cuts through the material, the actual distance will be about 0.2 mm larger than the cut-out material. That means a 100 mm cut-out actually required 100.2 mm of motion and the calibration will be incorrect.

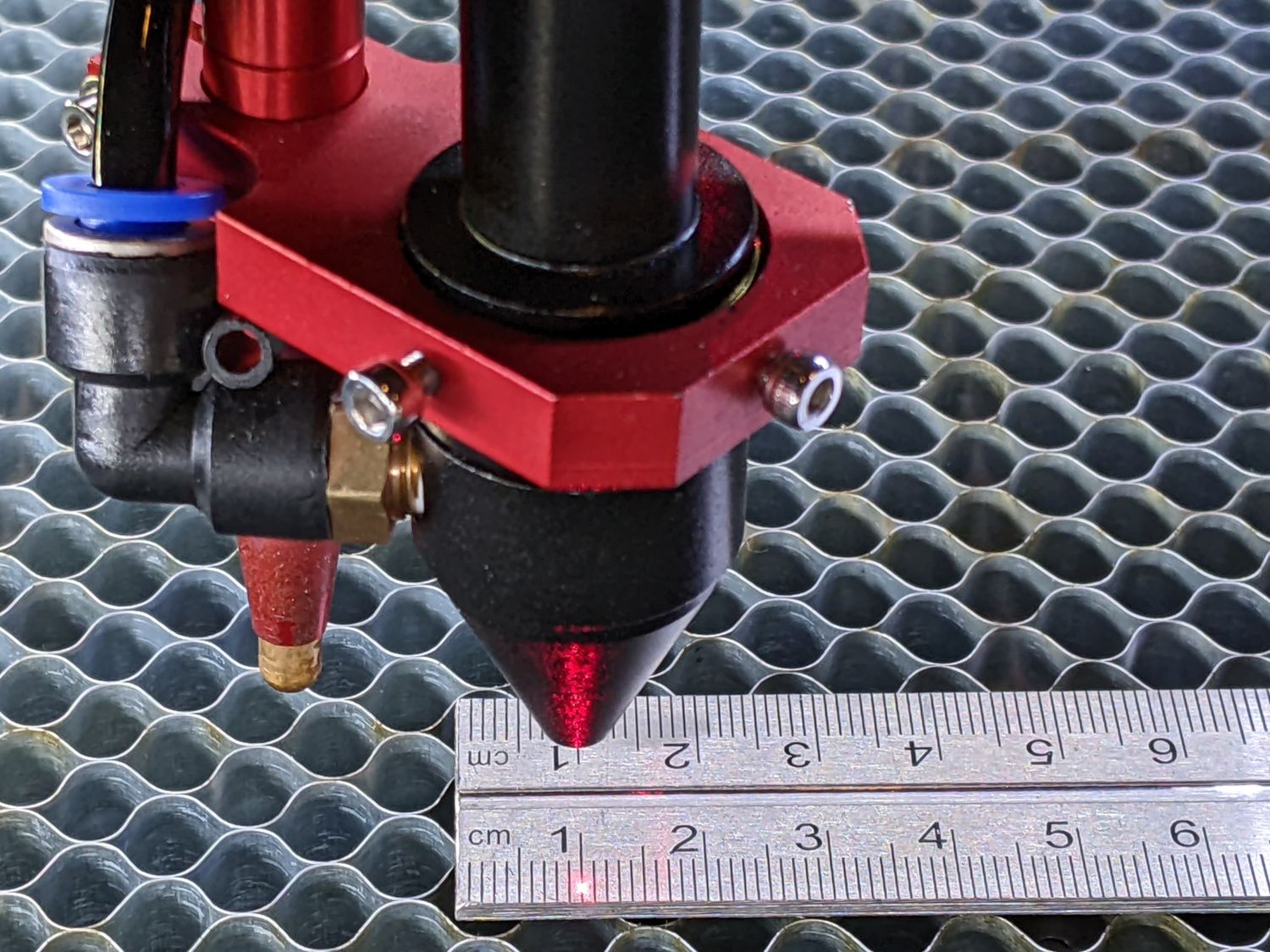

Recalibrate using either well-focused lines engraved on the surface or, if the machine has a red-dot pointer, manual moves without activating the CO₂ laser:

An earlier discussion has some pointers: