if you are going to cut thru with laser

(j-tech 3.8w)

Do you had to have something

under to protect the waste board.

It dosen´t matter if the edge is being burn

I don’t understand your question. Are you asking is you should do something to not cut into your “waste” board that will get cut when using your CNC?

Sorry Rick

I should explain better

I wonder if my laser 3.8w can cut thru 3-4mm plywood

And if so should I have somthing under to protect my waste board

I use X-carve

You can cut with this laser but it may take more than one pass. As for protecting the waste board…it is a waste board, so I am not sure what the concern here is. You can add another waste board to protect the first waste board if you want. You will just need to refocus if you do add another.

Thx Rick

That was just a thought

Some people do - even a thin sheet of aluminum can protect the waste board, but you’ll get reflections which might affect the cut quality on the back of what you’re cutting.

after the experience with a 5.5 watt laser i have done, it is not possible to cut 3 or 4 mm plywood unless you run 20-30 times. the result is not neat.

I’ve cut 3mm plywood with the JTech 7 watt. I ran something like 6 passes, lower Z with each pass, air assist, 100% power and around 10 inches per minute. It’s no racehorse, but I think the 3.8 watt will do it, just slower still and more passes. Air assist made the biggest difference, don’t think it’ll work without it. I ran a large aquarium pump, 1750gph, directed through loc-line and finally to an 1/8” copper tube directed right at the cut. In the end I bought a CO2 laser, it’s like 2000% faster and easier. It can be done for one-off pieces, but my candle holder projects took around 3 hours to cut with the diode, I cut the same candle holders in about 7 minutes on the CO2.

Edit: Get the wood up off the wasteboard so it can breathe, and clamp it down good, it’ll warp as it cuts and lose focus. I used 1/4” thick spacers under the edges/corners, then clamped on top of those just like if I was cutting with my router.

Dan

Use an Emblaser 2 with a 5 watt and will cut through 3mm ply no prob at these settings

150mm/min

3 passes

z axis set at 1.5 mm (in centre of ply)

If ply is warped even a tiny bit it it may not drop out so can reduce speed to 120mm/min.

Hope that helps.

if you invest in (4-5mm) balsa wood or special plywood without any cracks and impurities and based on indoor glue it is possible to cut through that tree, but it will not be neat.

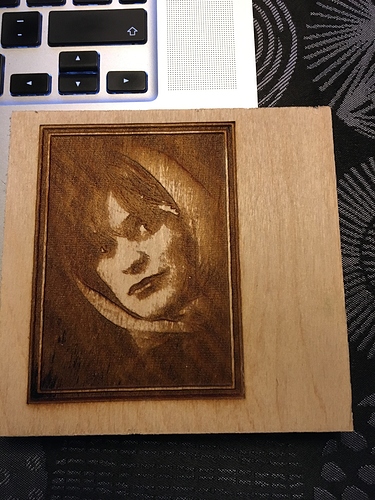

Don’t get me wrong, I loved my 5.5 diode laser especially with LB and primary for engraving. The results were very fine. In the attached image there is a scan which is approx. 2.5 mm deep and it appears almost three-dimensional. It is made with my old diode laser and T2L (before I found LB  )

)

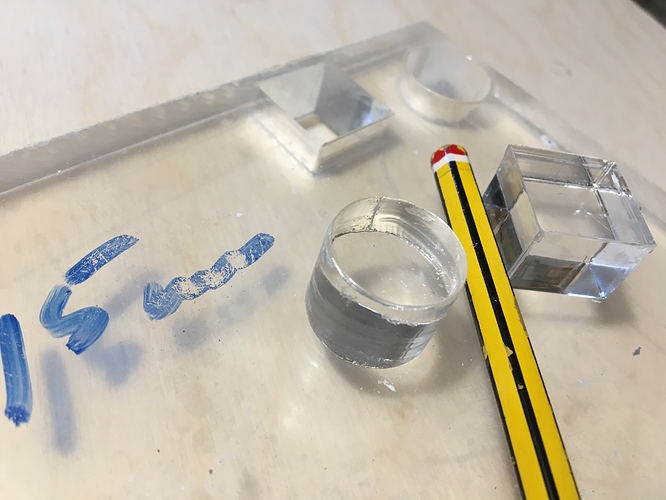

In picture no.2 are samples in 15 mm acrylic, burnt with my K40.

Sincerely

bernd.dk

I have access to a 2.5w laser and a 5w laser. The 2.5w will cut through “premium quality” 3mm ply at 8 passes and 3mm/sec but will not cut through 3mm structural ply (the cheaper stuff) no matter how many passes, whereas the 5w laser will do it with 4 passes on the structural and 2 to 3 passes on the premium.

This topic was automatically closed 14 days after the last reply. New replies are no longer allowed.