Hi, can anyone help me understand why very small line interval spacing creates dark marks on bare aluminum (as opposed to the usual lighter marks created by larger line interval spacing)?

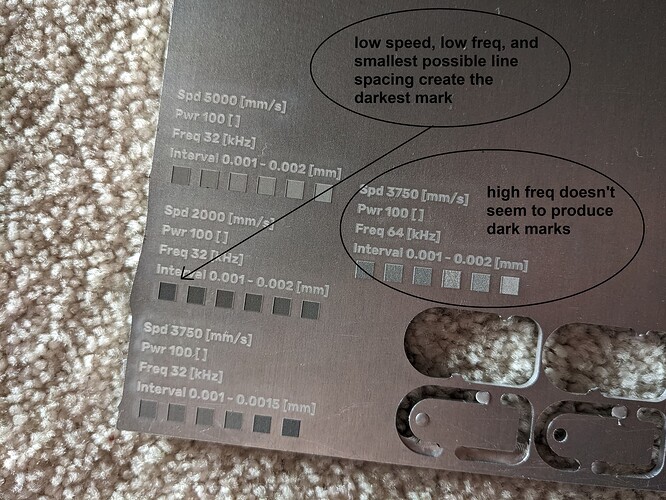

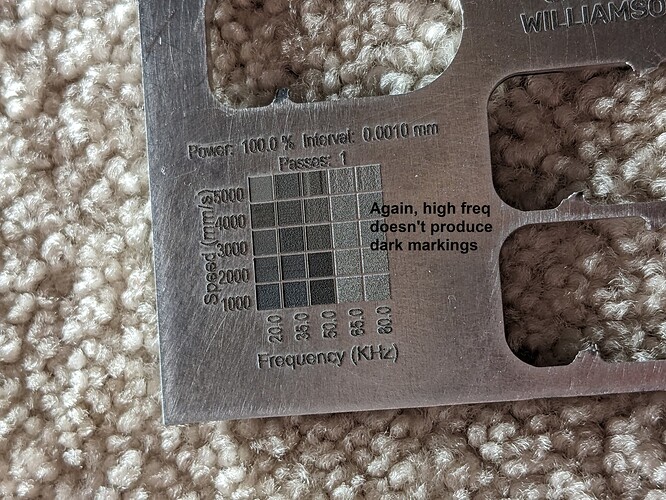

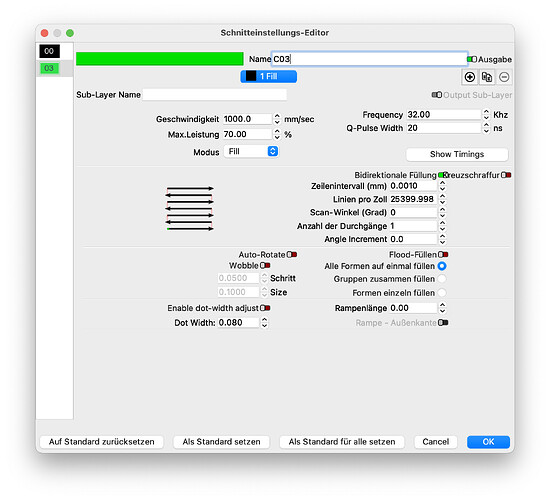

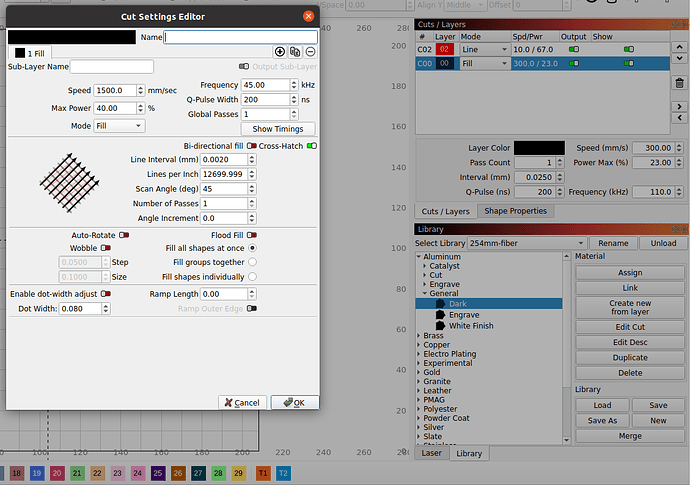

I’m working with a Triumph 30W fibre laser, 1064nm, ~0.08mm dot size. While trying to find good settings for dark markings, I ran the following tests:

In the image above, text was engraved with 0.01mm line interval. It has a very white marking compared to the base metal.

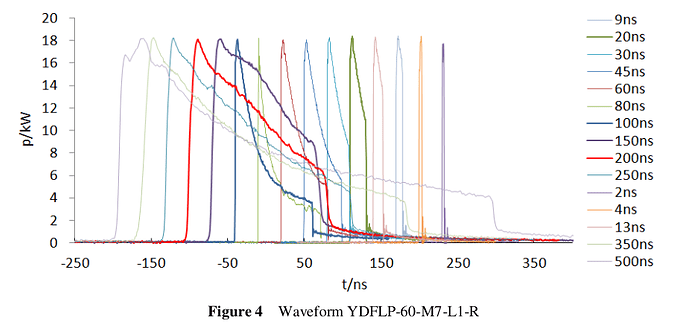

I don’t understand why using a tiny line interval creates a dark marking. At 0.0015mm, the laser dot passes over any given point of the material ~53 times before advancing, vs ~8 times at 0.01mm.

Does small line interval create some kind of “structural colour” effect like butterfly wings?

Or is it a chemical process where the laser blasts material off the base metal, oxidizes it, and then immediately bakes it back onto the base metal in the next pass?

The test above seems to indicate there may be some kind of speed/frequency sweet spot for optimal dark marking.

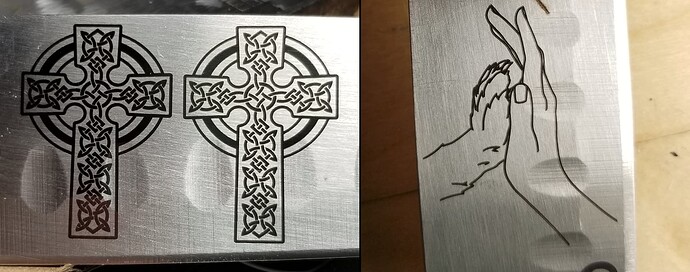

I’m particularly interested in figuring out the mechanism of dark marking formation, because I’m hoping it can be applied to raster image engraving.

At 220 DPI (the finest resolution I can engrave an image at), the laser marking is light compared to the base metal.

Consequently, I’m currently looking at dithering images onto dark anodized/powder coated aluminum, to maximize contrast.

It would be preferable, however, if I could dither raster images with dark markings on bare metal. This way I can achieve good contrast, while avoiding the excess steps/work of anodization/powder coating.

I’m not sure how this could be accomplished. Perhaps if the laser rapidly pulsed each “pixel” of the dither ~53 times? …

Any insight/advice about the mechanism of dark markings on aluminium is appreciated!