So this has happened a couple of times now. I create some text, and position the laser, and hit start. It goes, no problem. I change the wood, as I want to burn the same thing again, click start. Again, no problem. Change again, click start, and it moves to the bottom left, further then the limits of the machine (no limit switches) and starts. WTF?! Worked fine a couple of time before it.

The only thing I have tried to burn over and over again without repositioning the laser is text created in Lightburn. And it is hard to repeat this issue. I have done it 4-5 times with no issues, but I have also done it twice, and had issues on the second burn.

I have one of those ‘cheap’ 3018 pro jobbies with the laser attachment.

Inspect the limit switches and any connections for bad contact or wear. Check the entire length of the wiring for any fraying or cuts. Make sure the connectors are firmly seated on both sides of the cable. You may be getting an intermittent failure or short.

Is it failing to stop along both axes or just one? Try swapping the limit switches. Does the failure follow the switch or remain the same? If it follows the switch the switch itself is likely bad. If it stays in the same spot then likely something in the wiring or on the board.

So first off, I have to know… Did I write that badly? Or did you just not bother to read it? It clearly states I have NO LIMIT SWITCHES (at least I think it clearly states that.) i am willing to accept that its my bad writing…

So, I checked all the wiring for my limit switches… They still didn’t exist, so I am guessing that’s good.

It doesn’t fail. It prints just fine, just occasionally it start decides it wants to move to some place far down the bottom right before starting. I have it set to start from current position (maybe that one is my bad, I should have mentioned that?)

So right now, I am using the trial version of the software. I have to say, if it is going to do this, this software isn’t going to work for me. So far I like it, but I need to get it working properly before final purchase.

Based on the topic and the way the situation was worded I interpreted the core problem to be that the laser was attempting to home and not respecting the limit switches. It wasn’t clear to me that it was the specific direction and magnitude of travel that was the concern. “It moves to the bottom left” was not presented as a difference in behavior from the previous two runs. Only that the laser head moved beyond “the limits” of the machine. This was why I focused on cases where limit switches weren’t being respected.

With your clarification I can see that you meant to call out specifically that no limit switches were installed.

So having established that, first check your limit switches…

In the first post you mention it moving to the bottom left. Is it doing both of these unpredictably or was one of these just a typo?

Some additional context questions:

- Can you explain in some detail your alignment procedure? When you say you “position the laser” how and where are you doing this?

- What is the location of the work material in relation to the overall laser bed

- Are you going through a specific power-on process when you start your laser? Or just powering on wherever the laser head happens to be?

- Have you gone through any specific GRBL configuration to get your laser to work with LightBurn? If not, don’t start making changes yet. Just want to understand what you’ve done.

- When you startup the laser and LightBurn for the first time, in the Move window push “Get Position”. What is the value shown there?

- In your original scenario where you start the burn 3 times, are you literally placing the work material in the same spot each time, and just hitting start? Is there any realignment happening going on between steps?

Additionally, can you provide the following?

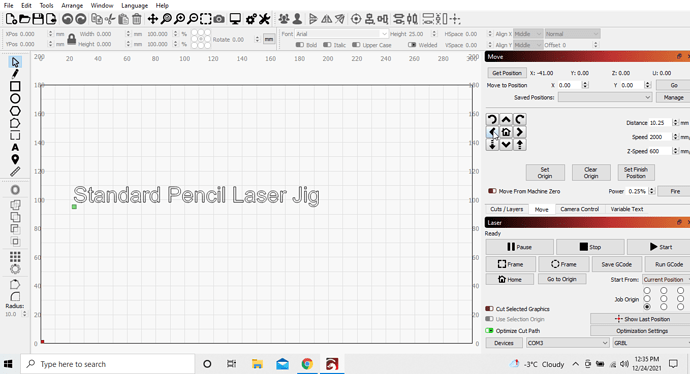

- Screenshot of full LightBurn window as if you are about to start a burn (after all alignment procedures). Attach in a response.

- Enter these commands into the Console window one at a time. Then send back output here.

2a) $I

2b) $$

2c) $#

2d) ?

I tend to think this won’t be a problem with LightBurn sending different commands for each burn. It’s likely that some context is changing in between burns.

Sorry, not random, both times, it went to bottom LEFT.

Please note, I am not at home in front of the laser as I reply, so I not be able to give you exact wording.

- “Alignment procedure”

I click the “Fire laser” button to turn on the laser at 0.25% so I can see where it is. I use the Move or Jog buttons to move the laser to the bottom left of where I want it to burn. I shift click the “Outline” button, so I can see exactly where I want it to burn. Once it is exactly where I want it, I click start. - “Position of work material”

Its a bit (Maybe 1-2 inches) up and right from what would be the bottom left. Maybe 3-4. Its wherever I am able to get it to clamp to my satisfaction. Both times it happened the material/laser was in about (1-3+ inch difference) in the same spot, with 2 different patterns to burn. - “Power on procedure”

I push the power button in the back. It turns on. That’s all I do. - “Specific GRBL commands”

I have tuned it to increase the speed following documentation I found elsewhere. I have also entered the $32=1 command (I think its $32=1) to switch from spindle to laser mode. I haven’t done anything else as far as GRBL commands. - “Push ‘get position’”

I am not at home right now, but when I get home, I will do it. I can however tell you that when I have pushed it in the past, whatever numbers were there did not change. It does not seem to be getting anything from the controller on position (What I assume that button is designed to do) - “Place material in the same spot each time”

Yes, that’s what I did. Take off the first item, put the other item down, and click the left mouse button to start. No movement whatsoever. Please keep in mind the first time it happened it happened after 3-4 “successful” burns. The second time it happened it happened on the second burn. The second time I did however increase the power of the laser (but no more adjustments) I have also been able to successfully burn the first ‘pattern’ 6-7 times in a row without issues. The issue seems to be random (the most fun to diagnose!)

1 & 2

I will get you them as soon as I get home. (Couple of hours.)

Finally, I think your right. I don’t think its a “problem” with lightburn. I could be wrong, but I think its much more likely that I am doing something wrong myself. But that’s why I am here, right?

Based on what you wrote before I’m assuming this is with “Current Position” set. Can you confirm the job origin position when you did this? I assume bottom left but please confirm.

Also, is what you plan to burn the only thing in the entire workspace? Nothing to the side or outside the workspace boundaries?

With non-homing machines you’ll typically have to move the laser head to the “home” position before powering-on. This will be the workspace 0,0. However, while I suspect the problem you’re having is related to the coordinate system what’s odd is the unpredictable behavior. That’s going to be the key to figuring out root cause.

Ok. Will likely need to make at least some status reporting changes and possibly coordinate changes but will need the data you send and possibly some more probing to know.

This is interesting. I would expect it to provide you at least something even if it’s not what we like.

I don’t like this. This doesn’t point to anything obvious and will also make it hard to test.

Really it comes down to either some condition is changing that LightBurn is reacting to and sends a different set of instructions for those odd jobs or somehow the laser controller is getting the same instructions but is doing something different with it. Unless there’s a malfunction in the controller I have to think that LightBurn is sending the different instructions. Only question is why. Right now I suspect it’s related to position information not being available. But I don’t understand why the behavior is not 100% repeatable.

Okay, so $! results in the “status” saying “Busy” indicator is at 100%, but it won’t do anything. I need to unplug and plug in again. The rest follows:

ok

$$

$0=10

$1=25

$2=0

$3=2

$4=0

$5=0

$6=0

$10=1

$11=0.010

$12=0.002

$13=0

$20=0

$21=0

$22=0

$23=0

$24=25.000

$25=500.000

$26=250

$27=1.000

$30=1000

$31=0

$32=1

$100=800.000

$101=800.000

$102=800.000

$110=1900.000

$111=2400.000

$112=600.000

$120=1800.000

$121=1600.000

$122=30.000

$130=200.000

$131=200.000

$132=200.000

ok

$#

[G54:40.000,30.000,0.000]

[G55:0.000,0.000,0.000]

[G56:0.000,0.000,0.000]

[G57:0.000,0.000,0.000]

[G58:0.000,0.000,0.000]

[G59:0.000,0.000,0.000]

[G28:0.000,0.000,0.000]

[G30:0.000,0.000,0.000]

[G92:0.000,0.000,0.000]

[TLO:0.000]

[PRB:0.000,0.000,0.000:0]

ok

?

<Idle|MPos:0.000,0.000,0.000|FS:0,0|WCO:40.000,30.000,0.000>

ok

Yes, “Current position” is in fact set.

Yes, Job Origin position is bottom left, as can be seen in the pic.

Yes, it is the only thing in the workspace, and I always keep it in boundaries. I don’t know how it will react outside boundaries, so I just bake sure its all in there.

Moving to the home position evert time its turned on is close to impossible. It uses “worm screws” to move the laser and bed around. They are (at least one is) hard to get to and move by hand, a lot of manual rotating.

As far as “Get position” I gave managed to get it to give me something other then whats there. If I move the machine around using lightburn (To x 10 for example) Turn off the machine, unplug the machine from USB, turn it on and plug it back in, wait for it to connect, and hit “Get position” it resets to 0. I am assuming that is because when the machine is first turned on, it assumes position 0. And since lightburn was not restarted, it assumed position x10. But anyway, it does seem to be able to get the position. Just when I clicked “Get position” the position was actually what lightburn thought it was, so it didn’t change.

I hope that all helps.

and BTW, thank you for the help/.

This should actually be $I (as in capital letter I). This is just to get version of GRBL. Wanted to make sure we were dealing with a relatively newer version.

I still haven’t seen any smoking gun as to what could be causing your original stated issue but I do see that there are some general tuning things that can be done which could affect the issue.

First off, take a backup of all your current settings by going to Edit->Machine Settings, then Save. This will allow you to go back in case some of this goes sideways.

This is inverting your Y-axis. Do all the jogging direction in the Move window work as you expect? Left goes left, right goes right, up goes up, etc? If so, nothing to be done here.

This is setting position reporting to be based on machine position. We’ll need to change this to work on working position. All changes consolidated farther below.

These numbers set the number of steps per mm travel. This looks really high. Are your burns dimensionally accurate against your designs? If so, no problem. If not, then will need to adjust this.

These are acceleration numbers which look really high for a 3018. Will suggest dialing this down. I’ll consolidate all changes farther below.

These are your work dimensions. Can you confirm X and Y? Z can’t be right.

This means that you have a work offset setup. Do you recall explicitly doing this? If not, no biggie, just unusual. We’ll zero this out so that your power on location is 0,0. You mentioned it would be difficult to move before being powered on. That’s okay, you can power on, move, then power cycle again to zero out.

All suggested changes consolidated here. Enter these into the Console window one at a time. Swap out the bracketed items with what you know for working area dimensions:

$10=0

$120=30

$121=30

$122=30

$130=[set this to x dimension]

$131=[set this to y dimension]

$132=[set this to z dimension]

G10 L2 P1 X0 Y0

These changes should allow you to use Absolute position in addition to current position. Absolute position is nice because your bed basically matches the LightBurn workspace.

Okay, thanks for confirming.

That’s fine for this test. There are other techniques for only burning certain shapes even as other shapes are in the workplace but something we can address later.

If I’ve understood everything correctly I think this is all good and should work fine with the above changes.

You’re welcome.

Try these changes and run some tests. Make sure to re-zero with the head at the lower left.

Things shouldn’t behave fundamentally differently than what you’ve seen but your get position coordinates should now be 0,0 at lower left and incrementing accordingly as you move up and right.

Assuming things work, try to coax out the odd behavior. I know it’s not predictable but is there a known upper limit for when you know you’ll be good?

Okay, so did the following

$10=0

$130=300

$131=180

$132=45

G10 L2 P1 X0 Y0

The $120-123 settings I configured myself and did a lot of testing to be sure they were good. I was surprised how high I got them as well, but unless you think it may be contributing to the issue, trust me, they are good.

So, I got it to do it again, twice. The first time I wasn’t smart enough to get any output, but the second time I did. Sequence of events, for reference:

Moved to a new position (Hit “fire laser”, hit right a few times to get it where I wanted it)

Hit “Start”

Machine started moving to bottom left.

Turned off the machine. (The USB keeps the controller powered, but won’t fire the laser to move the stepper motors. To recap. When I turn the power of the machine off, the offline controller is still lit up (says USB connected) and I can send commands to the device via the console. Don’t know if this is important, just putting this out there.)

Clicked “Stop” in lightburn.

So here is the output. NOTE: This is not JUST the output from the fail. I took output from the last burn and some movement as well, because I didn’t know exactly where one part ended and the failure part starts. Figured better to have too much information then not enough.

Starting stream

Layer C00

Layer C00

Layer C00

Layer C00

Layer C00

Layer C00

Layer C00

Layer C00

Layer C00

[MSG:Pgm End]

Stream completed in 0:06

ok

ok

<Idle|WPos:23.250,32.750,0.000|FS:0,5|WCO:0.000,0.000,0.000>

ok

Starting stream

[MSG:Pgm End]

Stream completed in 0:00

<Idle|WPos:28.250,32.750,0.000|FS:0,5|WCO:0.000,0.000,0.000>

ok

Starting stream

[MSG:Pgm End]

Stream completed in 0:00

<Idle|WPos:33.250,32.750,0.000|FS:0,5|WCO:0.000,0.000,0.000>

ok

Starting stream

[MSG:Pgm End]

Stream completed in 0:00

<Idle|WPos:38.250,32.750,0.000|FS:0,5|WCO:0.000,0.000,0.000>

ok

Starting stream

[MSG:Pgm End]

Stream completed in 0:00

<Idle|WPos:43.250,32.750,0.000|FS:0,5|WCO:0.000,0.000,0.000>

ok

Starting stream

[MSG:Pgm End]

Stream completed in 0:00

ok

ok

ok

Starting stream

Layer

Layer

Layer

Layer

Layer

Layer

Layer

Layer

Layer

Layer

Layer

Layer

Layer

Layer

Layer

Layer

Layer

Layer

Job halted

Stream completed in 0:04

ok

ok

ok

ok

ok

ok

ok

ok

ok

ok

ok

Grbl 1.1f [’$’ for help]

ok

Okay, so as soon as I posted that, I decided to go play again. This time it did it without repositioning first. I just did 5-6 burns, repositioned, did 2-3 more and BAM!

Starting stream

Layer

Layer

.

.

Can I ask a question. “Layer C00” that appears in the console… Is the controller sending that? Or is lightburn putting it there for our information? Cause if its the latter… I think I found a bug…

Anyway look forward to seeing what you have to say.

Well on the bright side I’m glad that the setting changes didn’t mess up everything but disappointed that it made no difference. It makes sense given the symptoms never quite fit.

At least for the basics:

- Can you confirm that the laser zeros to 0,0 at power-on? And that you can re-zero from the lower left?

- Similar to above, are you getting positive only values for every position above and right of 0,0? As in do you get 300,180 if you go to upper right?

If you’re good on the two items above can you switch to Absolute Coords and see if you can reproduce the issue?

I believe this is from the comments that LightBurn sends to the controller in the g-code. What did you find about this?

Yes, if the unit is powered off, and the USB is disconnected, when everything is reconnected and I press “Get position” it gets 0,0,0.

Yes, when I move from bottom left the numbers are positive.

So, if I use absolute coordinates, doesn’t that mean I need to have the image exactly set to the right spot in lightburn? Sorry, I haven’t used absolute coordinates, so I don’t know how it works. You will have to give me a brief rundown if you want me to try and use them.

Another interesting bit of information. I tried a different computer. I was able to do 20 burns without the issue coming up. Max lately with the “old” computer is 7, usually 2-3. So I am thinking lightburn for some reason just doesn’t like this computer. Since the sole purpose of this computer is to run the device, I am gonna try and go nuclear, wipe the system and start from scratch. I will post details when I have some.

And I didn’t find anything out about this, that’s why I asked. If lightburn is sending one thing (Layer C00) when it works, and something different (Layer) when it doesn’t, the only thing that is different is what Lightburn sends, leading me, as a troubleshooter, to determine the problem is somehow with lightburn (or a setting therein, or something).

Is that what happened? You saw different output in the errant case? That’s… interesting. Not sure what to make of it. I’d expect it to just fail rather than doing something odd but otherwise fine.

Just think of the LightBurn workspace as representing your laser bed. So where in LightBurn you place the object will need to match the location of the work material on the bed.

Use the framing feature in the Laser window to make sure you’re within boundary. If you haven’t done so already, turn on Fire button in Edit->Device Settings. Then in the Move window set the power level of the fire button to something low like .25%. Push the fire button to test. If .25% is too low bump up slowly until the light is visible. Of course make sure you have safety glasses as you do this.

To use the laser while you’re framing push the Shift key as you click the frame button in Laser window.

I can’t think of anything that would cause these specific behaviors but I’d be glad if that’s all it was. You may want to try a different USB port to see if that gives you different behavior before wiping.

Trying to follow your post here. I have a couple of these machines.

Suggest when you change any of the control registers or $ values via the Lightburn ‘Edit → Machine Settings’. This will help you ensure you are modifying the proper registers, as it’s also in English in the GUI.

I’d suggest you go through the Coordinate and Job Origin documentation. You will probably still have questions about it…

I run many of my jobs in ‘absolute’ mode, that require placement. You will see advantages in all three types depending on what you are doing.

If you are going to modify your machine, I’d suggest limit switches.

I did understand that any time the machine is powered up that the head is positioned to the bottom/left?

Lightburn has been ‘beaten up’ pretty well and they do find bugs now and then. With this software I make many efforts to understand what the software is expecting and change the tact before I even post a question. I haven’t found a bug in my couple of years and I use it daily.

Take care

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.