Hi there.

I have been looking, but don’t seem to be able to find this exact issue.

I have a Sculpfun S9.

Just recently fitted the extension kit, and very pleased with it.

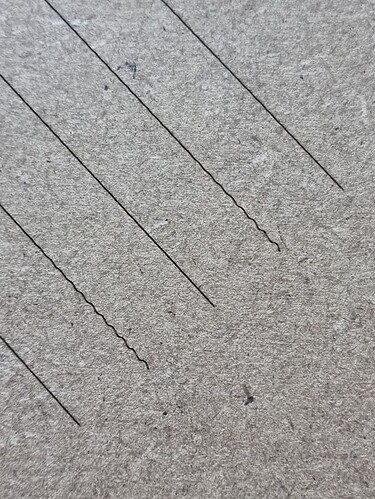

I have just noticed that my diagonal lines are now slightly wavy.

Horizontal, and vertical look perfect, but the diagonals are off.

I have adjusted the belts both ways, with no effect.

I have adjusted the tension on the wheels to frame assembly, also no effect.

Any ideas?

Can you take a photo of what you’re seeing?

Just spotted the issue.

The module itself is very slightly vibrating at the start of the cut.

It’s not so visible in the vertical line, as that’s the direction of the vibration.

Just tightened some of it out in the rollers.

I think it may be a good idea to upgrade the head to the linear bearing.

Can the ramp up speed be adjusted, so that the start of the cut moves off progressively?

I’d also suggest taking a look at wobble in the laser head assembly. Not sure if that’s what you tightened up but draw the wheels closer to the gantry railing with the eccentric nuts if there’s any gap. Don’t overtighten.

This would have to be done in GRBL configuration.

$120, $121, $122 – [X,Y,Z] Acceleration, mm/sec^2

This sets the axes acceleration parameters in mm/second/second. Simplistically, a lower value makes Grbl ease slower into motion, while a higher value yields tighter moves and reaches the desired feed rates much quicker. Much like the max rate setting, each axis has its own acceleration value and are independent of each other. This means that a multi-axis motion will only accelerate as quickly as the lowest contributing axis can.

Again, like the max rate setting, the simplest way to determine the values for this setting is to individually test each axis with slowly increasing values until the motor stalls. Then finalize your acceleration setting with a value 10-20% below this absolute max value. This should account for wear, friction, and mass inertia. We highly recommend that you dry test some G-code programs with your new settings before committing to them. Sometimes the loading on your machine is different when moving in all axes together.

Thanks for the explanation.

It was the eccentric cam that I tightened up a touch.

The description on the acceleration will help no end.

Thank you.

Maybe check the rest of the mechanics as well, those are not really adjusted from factory: Guide to mechanical adjustments and maintenance - Diode Laser Wiki