Most hobby lasers are cw (continuous wave) whereas the fiber lasers are pulse lasers.

I have an M60 JPT M7 MOPA fiber from Cloud Ray…

Some sources will not allow adjustments to, what’s referred to as q-pulse, which is the duration of the pulse.

I don’t know what else you can actually use these for, some do types of plastic but it’s generally for metals… that’s what I bought it for…

Most lasers will damage materials outside of the useful range, but it’s not always a good job… However co2, will effectively do acrylic, it’s a man made product…

I’ve tried mine on wood, it does virtually nothing. On mdf it blow holes in the layers as it heats the glue up… it goes right through glass and acrylic without any damage… On a slice of baloney there is no effect, but some very, very slight warming.

These are brass coins from Amazon…

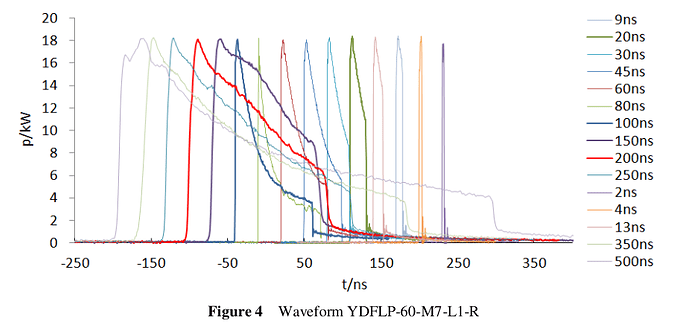

This is from my jpt source manual… you can see it pulses at very high power levels… I’ve had mine since February and I still can’t really drive it… Not only do I have speed/power but now there is frequency and q-pulse to add on to that… I can do great burnt coins from brass, but haven’t really figured out how to put together a clean pass to make it look good.

Don’t know if I answered you or not… you’ll have to advise…

Might be a good idea to be more specific on what you want to use it for… what you gave me to go on isn’t much… if you stick with the co2 for natural materials and fiber for man made, you’ll at least be in the ball park.

In the end you have to pick the type of laser by what you want to do with it.

Fiber lasers are not low cost… I have this one…