Hi,

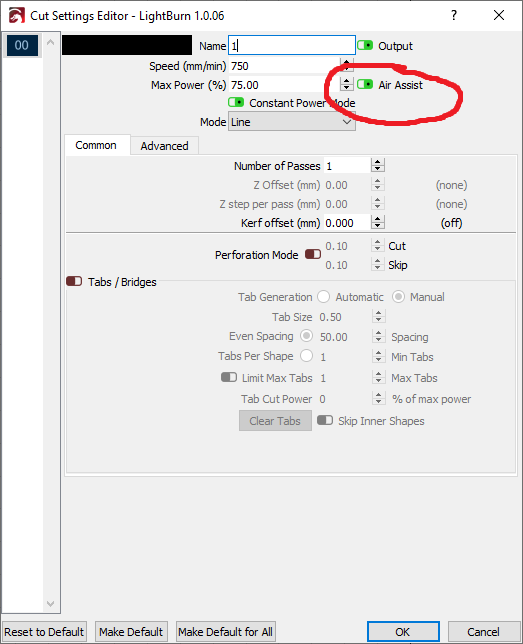

I need to disable the automatic air assist function because it blows away my fine wood veneer pieces… The Aux.Air button on the panel doesn’t seem to do anything, air is always on.

Does anyone of you know how to shut the air off?

Thank you! Mirjam

OMG, of course! ![]()

![]()

Thanks!

You have a small valve by the nozzle, if I remember correctly ;-), turn it all the way down, - almost. There should always be a minimum of air to protect your lens.

Unfortunately, the software solution does not work, the air pump is hard-wired, without contact. (even if there is an electrical outlet with an associated switch on the machine)

If you know an electrician who will help you, he could connect the cable from the air pump to the outlet, intended for the external air pump I wrote about. This will allow you to start and stop the pump manually.

If the air pump is to be controllable via the KT332N controller, a 24V / 220 relay must be installed.

Hi Bernd, yes I realized that right now!

No turning off via LB…

The “problem” is: As we have seen the other day I have to put a card stock layer under the veneer because the honeycomb “burns” the wood. But I need both sides to be clean…

The card stock (very white) does not absorb the laser, so does not get cut and won’t release the air into the belly of the beast. The air bounces back under the veneer and displaces the pieces - not good!

I’ll try the valve! ![]()

Thanks, Mirjam

Yes, reducing the air to almost zero works!

This applies to diode lasers but not to CO2 lasers, here the wavelength is ok for cutting in white material and also in clear acrylic.

I assume your settings are not optimal for your material.

Come up with your settings, we’ll look at it.

The settings are optimal for the wood veneer, but won’t cut the card stock, which is good because it protects the underside of the veneer…

But you are right I have seen after several passes it has burned through too.

I’m cutting the wood veneer (ca. 0,5 mm) with 40 mm/s, 15% - beautiful cut!

I assume tape is not an option for your parts?

Otherwise, even if it involves extra work, it is a good way to prevent soot and burn marks.

I work a lot with 0.6 and 0.8mm and have similar values as yours. But because my lamp parts are probably bigger than your fine parts, I have more options to avoid unwanted marks.

What species of woods have you used? I might try something in Maple.

It’s European Beech… I reduced the power to 12 %, the cut is basically invisible now.