Hello,

first of all, sorry for my bad english, i am from germany…

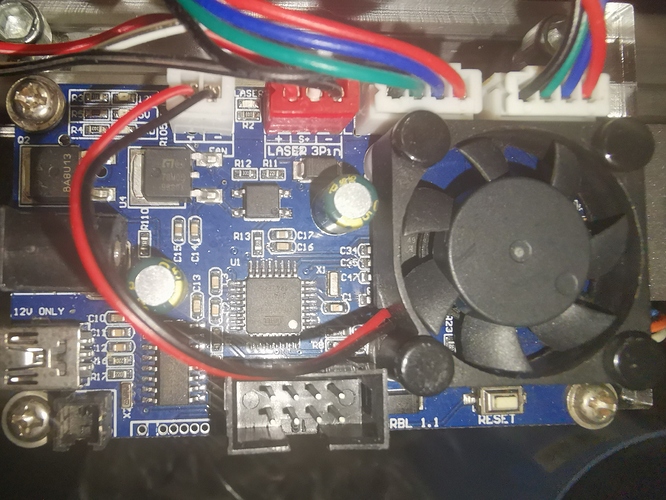

i tried out Lightburn and build myself a DIY Rotary for my 7W Chinese Diode laser. It is a simple Roller Rotary, i use it on the Y-Axis of my Laser, because the Board only have 2 Axis Connectors. It is a very simple A3 Laser. I tried to configure the Rotary Settings for my Rollers and the Stepper but it will not work correctly i think.

What i did so far:

-

i placed a marker on top of the rotary wheel. All the manuals in the web and youtube says i must find out the right Steps per Revolution for my motor, but in the newest Version of Lightburn there is only the Option “mm per Rotation”. So i tried some different values, until the Wheel is turning one time around and stop again at the Marker. When i use the Test-Button in the Rotary Window, it rotate 1 Revolution, stops and go back and stops again on the Marker. Everything okay, i needed the mm Distance of 40,20mm for that.

-

i measured with a caliper the diameter of the Rollers. It is exactly 39,50mm. I put it in the rotary Settings and put on a drinking glas on the rollers. On that point where it has contact on the Wheels it has 52mm in Diameter.

But here is the first problem, when i now press the test button and put a marker on the Glas, it will not stop on the marker. I tought i must measure the Object Diameter and put it into the Settings but i noticed the Object Diameter does nothing.

So i tried around and found out when i change the mm per rotation 74mm, the marker on the Glas does 1 Revolution. So do i must edit the Settings everytime i put on an Object with a different Size?

But the next Problem coming here, i put on the Workspace a Box with the height of 163.363mm. It should be the Curcumference of the Object, so 1 wrap arround, when i understand it right?! But when i use the click on page to travel method and click the end of that box, the rotary turns 4 times and stop on the marker. Why 4 Times?? And there is the Problem now, when i put an Object on the Workspace that have exactly 30mm for example, it comes out very stretched.

I tried so much stuff now, i placed so many different values in the settings, sometimes the wheel does turn 1 revolution, one time the glas do 1 revolution but whatever i try, when i put an object on the workspace with specific measurements, it comes out streched.

The only thing what worked so far for me is to place some paper arround the object, laser a box of 30mm on it and measure it with a tape measure. If it is to long, i reduce the mm per Rotation Value, if it is to short the opposite. I do it so long until the box is exactly 30mm on the glas. With that value then i can laser my Logo or something on the Glas. And it comes out correctly. But it is very complex to do so. Isn’t there a easier way for me? What i must put into the mm per Rotation Box? The Value for 1 Rotation of the Rollerwheel or the Object to laser??

I hope someone can give me some hints here, i don’t know what i’m doing wrong…

Thank you very much!