I know it’s off topic, but honestly I’m struggling to find any good info on this. Been hoping to hear from others. I’ve got a multi-purpose CNC machine with a 3D printing tool, a laser, and a CNC router. And, well, I’ve really been struggling to find information on the router stuff. Is anyone else familiar with any good cheap software for it?

Snapmaker 2, if you’re wondering what my machine is.

Vectric has several packages for routers. Some are basic and some are very advanced such as Aspire. I would suggest checking the Vectic site and see if one might fit your needs. They are a great company. They also allow you to upgrade at a reasonable cost.

I have an X carve 750 (great little machine)

I use Vectric desktop for all my designs and toolpaths.

As mentioned, Vectric is great software and the company is also very good to work with.

They also have a forum with very knowledgeable people to help you.

Hallo

Schöne Maschine, gute Verarbeitung.

Der Nachteil ist, das du mit dem Ding an den Hersteller gebunden bist (Module). Da geht nichts von der Stange bei einer möglichen Reparatur, oder Aufrüstung.

Zu deiner gesuchten Software: Vectric Cut 2D, Vectric Cut 3D, Aspire. Was du dir leisten kannst.

3D Drucker: Slic3r. Pronterface.

Laser: LB. CAM Software, alles was dxf, 3ds und

stl ausgeben kann.

Viel glück

Sorry

Ich meine CAD Software.

Gruss

Yeah, you’re right about being limited to modules they make themselves. I think that I’m okay with that for now, as this is my first machine and I’m still learning. Thanks for the advice on software, looks like I’m going to check out Vectric.

Thanks everyone.

//

Ja, Sie haben Recht, wenn Sie sich auf Module beschränken, die sie selbst herstellen. Ich denke, dass ich damit im Moment einverstanden bin, da dies meine erste Maschine ist und ich immer noch lerne. Danke für den Rat zur Software, sieht so aus, als würde ich Vectric ausprobieren. Danke an alle.

I have my laser(s) mounted to my CNC mill. Naturally I’m using Lightburn for the laser work. For CNC I use Carbide Create, free version right now, to design simple 2D projects and Openbuilds Control for milling. So far they work well together. With this setup I’ve been doing front panels for various projects- I mill out the various holes needed to mount devices and then use the laser for marking the purpose/function for each device. The only tricky part is aligning the two layers between the two software/driver systems. I use a laser ablated laminate from Trotec laminated to either an aluminum or plexiglass substrate.

I use Mach 3 for my CNC router.

I use Carveco for my CNC. I tried everything listed above and more. They are all expensive compared to LightBurn. Carveco has all the power and ease of use, and no need for internet connecion. Certainly the best looking GUI.

This is a great free software and the author is very responsive.

I have a Shapeoko xxl for my CNC and use Carbide create/Carbide Motion for the controlling software. I like the fact that both are a GBRL type system. In fact I frequently use files on both. I can use pngtosvg to get a vector file to use on carbide create. I clean the image up and add or remove anything i need to. Save/export the SVG file and then import it into Lightburn to engrave onto tiles/coasters

i know that also Fusion360 can be used for a CNC

I use a cnc - a home-brew machine with a 2.2kW spindle. I run Mach4 and use Fusion360 for the design work, and for generating the g-code. Touch wood I have yet to have a problem with the g-code that Fusion produces. I’m not sure I like the way Fusion handles vector line drawing - very unintuive compared to, say, Illustrator or Affinity Designer, so any odd shapes I need get drawn up in Designer and exported as an svg file.

This may not help too many with this, it is the way I do it anyway.

I make my drawings in Illustrator, mark any and all changes in direction, circle, etc. on the drawing. I then write the G-code for the changes in direction, speed etc.

Antiquated? Probably, but I have been doing it this way for forty five years and it still works. Lol

I have a small 3040 cnc and use Mach3. Import G code from LB to Mach3 I have not tried, but as long as it is 2D it should be possible, I just did not need it.

I use Vectric Vcarve Pro for my scratch built CNC router (5x5’ coverage 3HP water cooled spindle).

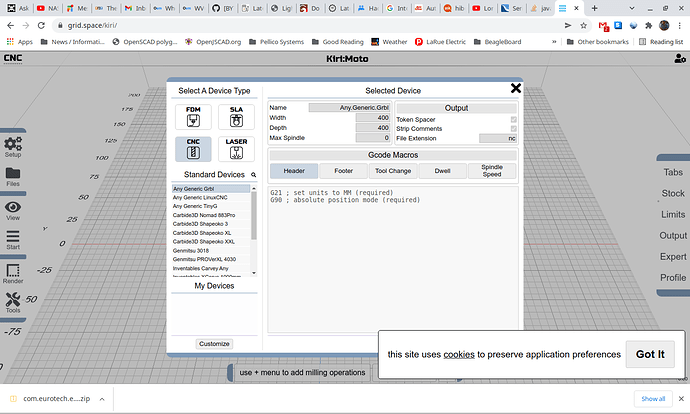

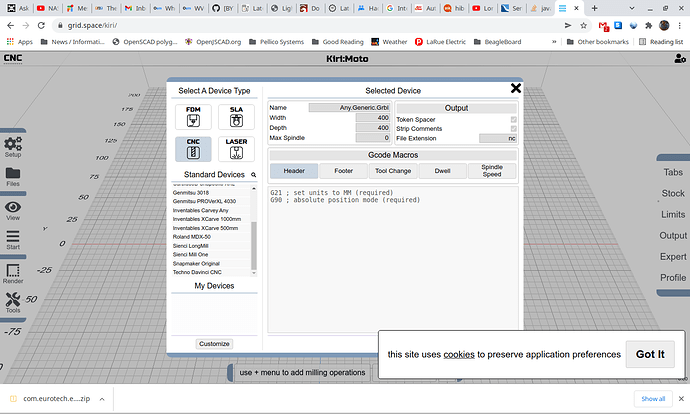

I use Lightburn on my lasers and have used Kiri:Moto for toolpath generation(gcode) for a Chinese 3040 CNC when running GRBL. Kiri:Moto is free, opensource and while it runs in your browser it is NOT cloud based. It literally runs on your computer in your browser.

My situation is a little different.

Until a couple months before COVID we retired from our woodworking business. I have a 3W diode laser and an Omtech 60W CO2 plus a two head industrial router with a 24” x 48” vacuum table. A computer genius neighbor rewrote the original files from MS DOS to Mac several years ago.

The router runs on G-Code. I actually taught myself to program making it much cheaper and more convenient when it came to writing for the many wooden products we manufactured and sold world wide.

It sure would have been nice to have LightBurn when we bought the machine in 1986

I forgot to mention that Kiri:Moto supports a number of machines besides generic GRBL based CNC machines. Kiri:Moto