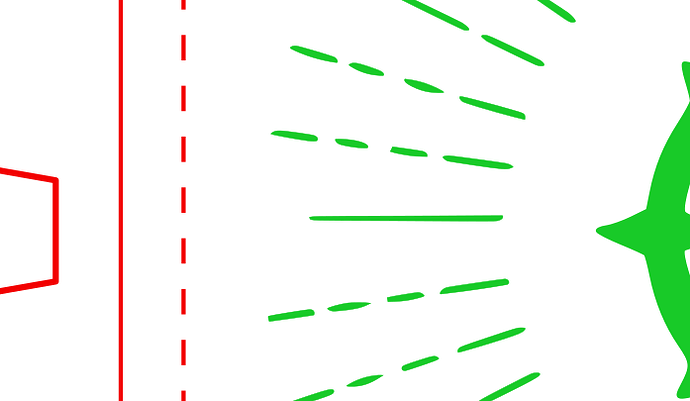

Hello, I am using the latest version of lightburn and when I make a line, it does it well, but if I put it in fill it makes me a double line, it only does it when it makes a double run, if I put it It only burned in one pass and on the return it didn’t burn, it doesn’t cause that defect… I have set a height of 0.07 (interval mm)

Looks to me like you could benefit from scanning offset adjustment. Scanning Offset Adjustment - LightBurn Software Documentation

I’m more inclined to believe this is the laser beam striking the nozzle and reflecting. If you look at even the filled areas in the middle of the pattern they are offset too. Anything that is straight up and down, does not show the offset as much. Which makes me believe that the laser beam is striking the nozzle somewhere near its 6:00 or 12:00 position causing the secondary reflection of the beam to always show on horizontal lines as a vertical offset. I would suggest checking mirror 3 and confirming that the beam is not striking the nozzle on the way to the material.

[Edit: Sorry, my assumption was based on the idea that you had a CO2 gantry style laser.]

This is definitely a belt tension issue.

I am assuming however you are moving your design with a 90º offset

the laser moves Up and down primarelly?

So you need to confirm 2 things

a) Left and right belt are with the same belt tension. You can pluke them as a guitar string to hear them, should sound similar. Make sure they are nicely tight…

b) frame is square with your X. Move X to the full front of full back and confirm left and right distance to frame are similar

Lastly, make sure your homing is repeatable

Create a small cross partern at say x200 Y200

Home → engrave

move frame by hand

Home → engrave again

There should be a perfect overall of both engravings

Thanks for the answers… the laser is a 5w falcon placed on an ender 3 pro. The issue is that when I remove the bi-directional fill, it does the job correctly, and when it makes lines it also makes them correctly (look at the thin lines on the left)

Yes, which is why it is something mechanical on your belts, the fact the distance is so exact between lines is a clue too.

Could be belt slack, or slack on the bracket that holds the laser but is definitely something that as machine changes direction is adding an extra 1mm/1.5mm spacing consistent. This consistency is what makes slack to be the primary source of the problem

Well, when I use the normal 3D printer, it prints well, I have no problems with inconsistencies in the axis… and the simple lines also print well… I will check that anyway, thank you!