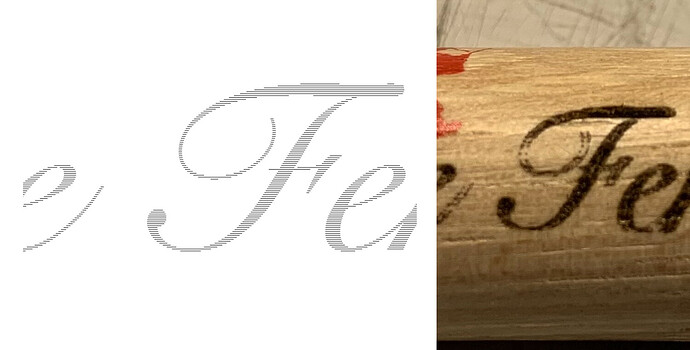

Started noticing some kind of double lines which are obvious where the line should be very thin. Can’t see that the belts are wrong. Can it be so that I need scan interval to be set or is this some other issue you think?

Looking at the image shown not only do you have a double line but all the image looks like a double burn with the material not secure. the long stem of the F is too wide.

Thank you! Yes it’s more than the thin lines but it’s most obious there that something is wrong. You mean that the material is moving around?

I would bet money you’re using USB. Switch to ethernet or send the file to the controller first then start from the controller, don’t use the start fom LB. LB resends the file when pressing start and corruption occurs.

Thank you. Yes I use USB and my engraver do not have Ethernet. I have LB transfer mode to Buffered but you think it can still go wrong?

Not sure where this information came from. Can you elaborate, please?

Do you have ‘Overscanning’ set for that fill, if so, set to what?

Can you draw a rectangle, say 50mm, set the fill the same as you have used for your text (same speed, power and Fill settings like Line Interval) and run that to see if you are getting the same effect? Show a close picture of the result and we can go from there.

Yes, standard 2,5% overscanning is used.

I will happily do as you suggest but I’m not at the machine for another two days probably.

When you can, it’s fine. We will be here!

I ask about overscan, as the image you posted looks dark at the edges more than double-lines. You could try to increase that a little to see if that helps. Overscan allow the head to move past the last burn spot, allowing the head to slow, prior to reversing direction. Extending that distance might be worth a test.

Thanks but I don’t understand. For instance the thin areas of the F should be a very, very thin line but there are two. Unless you mean that the overscan is causing burning to happen before and after the thin line but not the line itself.

If you post this file, we can take a closer look. What control system are you using to drive this laser? You say, “Cronos” in your profile, but do not identify the controller, ect.

It’s a GRBL device with rotary but I don’t have so much more technical knowledge about the controller. Is it something I should look up from LB? Here at least is the file.

janfernstrom2_backup.lbrn (52.5 KB)

So this is what I’ve tested and there is no noticable difference:

- Checking focus

- Increasing and disabling overscan.

- Disable bi-directional scan

- Improve traction on the rollers to make sure the material is not moving.

- Reducing speed

- Increase dpi

Any ideas?

We can close the case. I tightened all the screws again, refocused, cleaned the lense and now the problem is gone.

Glad you got this sorted. I looked at your file and do not seeing anything in there that draws my attention. Was going to suggest you go through the system again to ensure everything is tight (no too tight) and working smoothly. You beat me to the finish line.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.