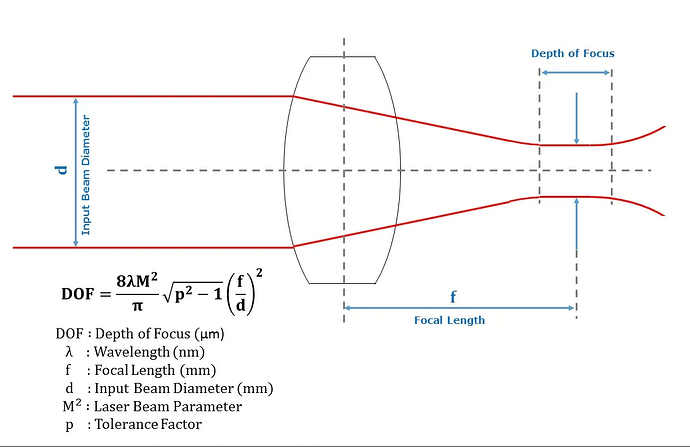

The Depth of Focus (DoF) increases proportionally with lens focal length.

BUT, there are two other critical parts.

The Focal Spot Dia (FSD) also increases proportionally. It doesn’t actually focus to a “point”, but a circle of finite diameter.

Double the lens’s focal length, double the FSD. But the area of a circle is the PI*r^2/. Double the dia, the area is quadrupled. The energy density drops by a factor of FOUR.

The last part is nuanced. A CO2 beam cutting thick material actually does NOT follow the profile of the point-up cone the beam expands on below the focal point. It cuts a straight walled channel. This is because a lot of materials are reflective to CO2’s 10.6um beam at low angles. The way cutting works, the beam naturally makes a “funnel” on top that tends to direct the light at low angles and direct it into the cut, “beam capture” and it “channels”. Once it’s in the channel, it will continue bouncing off opposing walls at low angles with surprisingly little loss until it reaches the bottom. It will NOT have a low angle when it contacts there, it delivers its energy and this ablates material on the bottom, deepening the cut and making more straight-wall channel.

On CO2, the 2" lens is best for this on most materials. Assuming the beam is 6mm dia (it varies, this is a number for some 130W glass tubes) at the lens, the cone of energy has a half-angle of 3.4 deg from vertical so it is easy to direct the energy into a channel.

A 1" engraving lens has a half angle of 6.8 deg, and it will NOT channel because that initial angle is too high.

You’d think a 4" lens would channel even better, but reducing the initial energy density by a factor of 4x tends to make it much worse. The only case I know of is 2" of microcellular PE foam. 4" lens will cut 1.5" depth with very clean vertical, parallel sides. The std 2" will cut about 1" before the channel craps out. I can get to 1.5" but it gets really slow and the channel isn’t very parallel anymore.

Beams don’t always channel. Like I say, a 1" engraving lens won’t. The capacity to channel does depend on the material and laser wavelength to. CO2’s 10.6um is great for this on many materials. Diode will be different. I do have small Atomstack laser diode machine too. I don’t know how it behaves with different focal lengths, I have never tried to change it

![]()