But that’s what I tried to set up in the tcon_tcoff_test_v04.lbrn2 test.

There’s some narrow bars on the left and right, intended to do exactly that. Turn off bidir, the skinny left and right bars are not read for cal, but to make a pseudo-overscan scenario. They appear as blue on my screen but are actually a blue bar superimposed over a red so they apply to both directions.

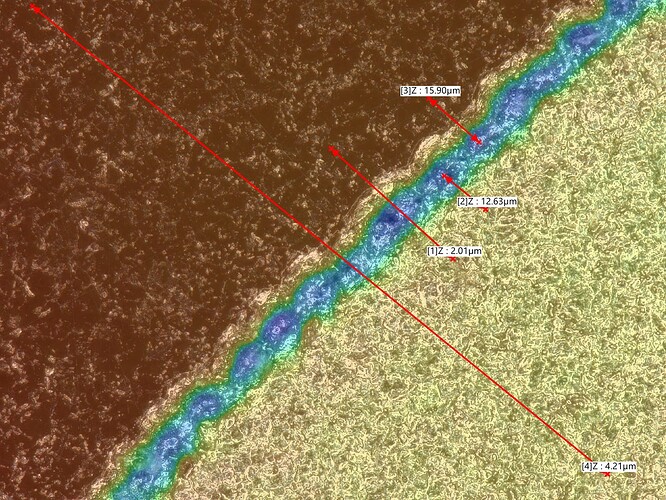

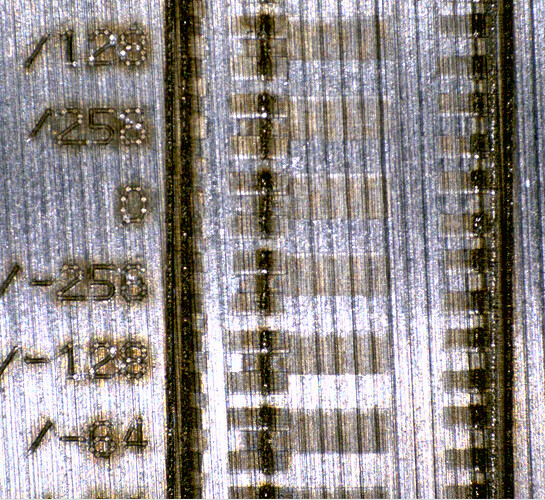

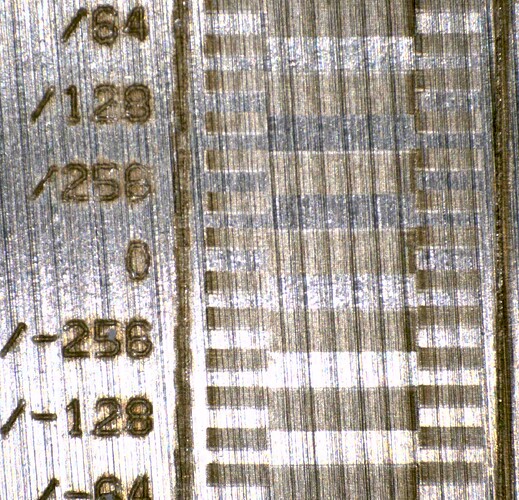

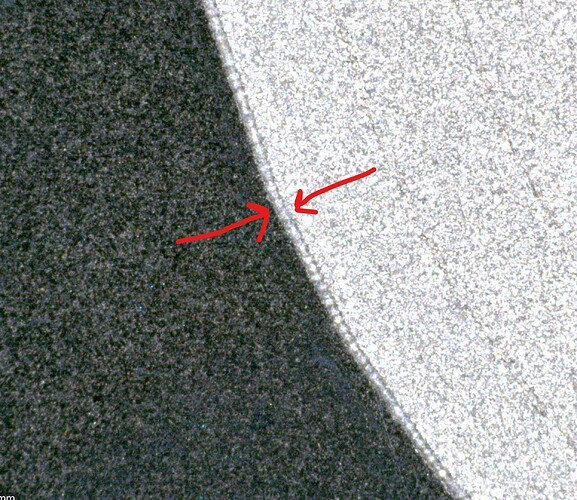

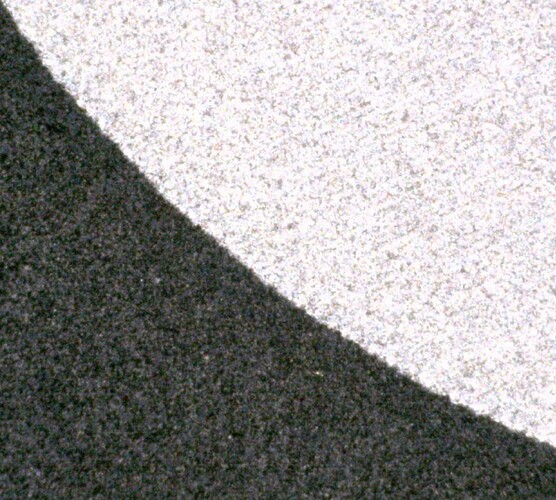

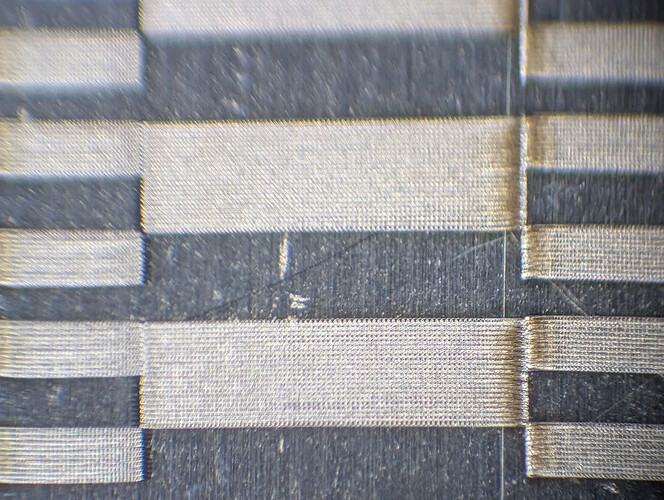

I got what’s shown below. The pulse freq/line interval were set up to space the pulses out at just a bit less than the spot size, minimal overlap. The second photo zooms in and is more telling, one side has pulses bunched up and the edge appears thicker because there are several pulses fired on top of each other as the mirror starts from a standstill. Now… ok, I’m not sure what is happening, that should be the trailing edge, not leading. The thick center bar is left to right, and I don’t think I 180’ed the pic. That should be trailing edge, and I thought there was no prob on trailing because the fire command stops first, immediately ceases the pulsing, but the mirror was just told to keep moving at CV to that point and overshoots, slowing or turning for the next thing it will cut, which shows nothing unless the Toff keeps the beam on too long.

Hmmm… wild theory here. Could the laser actually be scanning the opposite of what LB’s graphic is showing? The burn isn’t mirrored, but it wouldn’t necessarily have to be. If it’s mixed up, that would probably have to be inside LB not the laser. That is, the on-screen arrows and the command to the BJJCZ could be flipped. I’m gonna say this is “simpler” (for the purpose of Occam’s Razor principle of investigations) vs it braking to a stop before shutting off the fire command even though there’s more content on the line to fire for and it shouldn’t do that regardless. So I’d investigate that theory first.

The jog speed was higher than the cut speed, so this seems to show the mirrors have started on a bar on the left or right, did a rapid over the gap, then decided to come to a stop at the start point of a calibration bar instead of maintaining CV across the whole line.

Would anything change if this were two bitmapped images instead of Fill objects?

I do see the border bars are not running as a continuous bar from top to bottom as shown in the LB project. Both left and right bars are created as a narrow vertical bar running the whole height, with a red and blue copy superimposed. The one on the left has offsets that correlate with the blue test bars inside which run right to left. The one on the right has offsets that correlate with the red bars inside, which run left to right.

OK, what does that jagged border bar tell us? Let me think through that… take the bar on the left. Each line is always covered by an identical superimposed unidir of both directions (not bidir, which alternates left and right from line to line). Why is it jagged? Let’s think about the bar on the left, specifically its right edge. It reaches further to the right. It syncs up with the occurrence of the narrow side dashes, not the thick center dash. That’s blue layer, supposed to be moving right to left. There’s ALWAYS more blue content to the right of that bar, so…

“the right edge of the left border bar starts sooner if the prior blue content ended closer to it” (??!)

Am I thinking of it wrong, that it’s the thick red dash content causing it? Doesn’t seem possible, the period of the defect lines up with the narrow blue dash, not the red.

The left border bar’s LEFT edge reaches out further to the left when there’s no blue right-to-left dash on its right. Let’s phrase it as “why is the left edge of the left border bar further to the left specifically when there’s not a blue (right to left) dash nearby to the right? There is always more right-to-left dash to the right in both cases, it’s just further off”.

Now, I can’t entirely say whether this was the left-going pass staying on too long, or it’s a right-going pass starting too soon on the neighboring line above it. Neither of those make any sense to me. And the right edge of the right border bar is VERY dead-on.

This is a very small error at 5000mm/s. It could actually be a numeric rounding error somewhere, rather than a true Ton/Toff calibration. That sounds plausible, maybe the only possibility. Such a rounding error could be in the BJJCZ hardware or just in LB.

I’m a low-level hardware/firmware guy, does that make sense? Yeah, actually, it could definitely happen. The whole XY galvo coordinate system is divided up into finite divisions- probably 16 bits for the whole field (310mm plus some overscan area for the mirrors to coast past the usable edge, that sounds essential for the driver to work right). About 4 microns resolution. But the beam’s start/stop or start/duration is time, not distance, communicated to the MOPA, That could have idiosyncracies in sync or time resolution in LB, the PC-to-BJJCZ link, the BJJCZ FPGA RTL, the BJJCZ-to-MOPA link or the MOPA’s FPGA RTL.

Like the BJJCZ-to-MOPA link is a UART for power and an on-off modulation wire. But the BJJCZ has a time resolution in its sysclock-divided-by-something in both its start point and duration, and they aren’t always the same. Like if this were a microcontroller (it’s an FPGA, but for a thinking exercise), a single pulse created by a PWM might have a duration as a whole number of 100MHz clock cycles, but the start point of the PWM pulse might be sych’ed to a 1MHz timer.

But more relevant, again, depends on implementation, but the MOPA’s got its own clocking scheme for starting and stopping based on a different clock, and they’re not sync’ed. So this could be time resolution and/or time jitter between the BJJCZ and MOPA clocks.

Yeah I’m definitely overthinking it, but sometimes that’s where the problem lies.