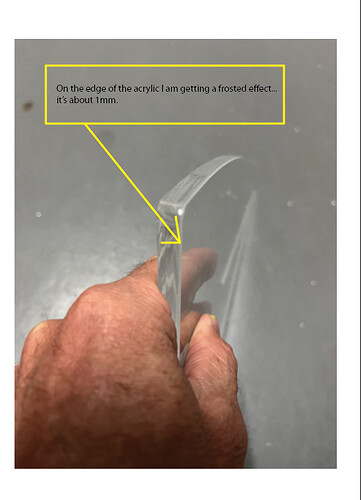

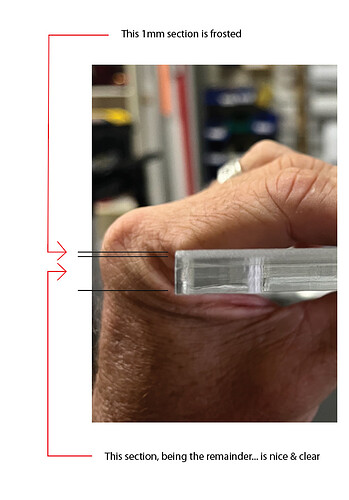

Does anyone know why I’m getting a frosted edge when cutting 10mm acrylic? Its only the first 1mm-2mm at the top off the acrylic that is frosted…the rest is clear.

It happens on clear & black acrylic.

Can’t you make a picture where we can see what you’re talking about? Please write a little about your machine and the settings you use to cut in 10mm acrylic.

I would guess too much air pressure…

![]()

I’m using a 100w laser, 4.5mm acrylic ( not sure what lens I’m using ), speed 2.5mm /sec, 80% max, 47%min, abt 7mm focus

Thanks Jack, I’ll try reducing the air

I just looked at my my materials library for acrylic @ 4mm is 7mm/s @ 80% (~16mA) and my machine is a 50watt China Blue. Tube puts out 44watts, which matches it’s length of 880mm.

I’d thought for a machine twice as powerful as mine, I’m wondering if my numbers got hosed up somewhere.

The lens length can also be a factor, but I usually cut with a 4", but for 4mm, I’d go with the 2" if I were engraving and cutting.

On some acrylic I’ve done in the past, I’ve engraved it with the compound lens, then changed it out for the 4" for the cut. The compound makes a much smaller dot and you can use it in acrylic.

Good luck… let us know

![]()

Is that frosty corner square to the cut?

![]()

Looks a bit rounded to me… The reason I was looking is that, on my machine when I run too hot, I think the entry point gets too hot leaving a ‘non square’ corner.

If it looks ok to you, then I’m fine with it.

The only other time I’ve seen it is when I use too much air pressure. I use only enough to keep stuff off the lens, a couple three pounds…

Good luck, keep us updated

![]()

Hi Jack, I understand what you’re talking about now in terms of it being square. When I examine it closely ( with my less than perfect eyesight ), it may have a slight curve and not be as sharp as the bottom of the acrylic. I might try increasing the speed? I guess at some point there will be a reduction in quality as the speed goes up.

I’ll do some tests, and will also play around the air pressure.

Thanks for your input.

Is the 1 mm along the top edge (the side of the acrylic closest to the laser’s nozzle) or the bottom edge which is right next to the bed of the scanner?

It’s along the the side of the acrylic, at the top ( furthest away from the bed )

How much air assist pressure do you use? Have you tried a test using full air assist and then another with barely any air (just enough to protect from backup into the nozzle so as to protect the lens) to see if that changes things?

I also work a lot with acrylic, usually, up to 10mm. With my old K40 and now with my OMT60Watt machine, I use only a little air and my cutting speeds are slower than “necessary” to get a polished surface. However, the speed should not be so slow that curtains are formed or the cut melts down. I think the frosty look comes from “too much” cooling air. I have never had this phenomenon.

Thanks very much for the information.It sounds like air is the issue. I don’t have a restrictor or value to control the air…I’ll need to get one & run some tests.

Hi Doug,

I’ll do a few tests with varying airflow & see how that goes. Thanks

@bernd.dk is correct about the air pressure.

I encourage you to try @Doug with high/low pressure. You will learn a lot by doing…

This is a simple ‘air assist’ you can rig up at low cost.

When you start adding air compressors and stuff the price goes up…

Good luck

![]()

I don’t have a restrictor or value to control the air…I’ll need to get one<<

If you want something basic and relatively inexpensive, these two types are what many of us have installed. Check your hose sizes. Also, I didn’t use these particular units and thus can’t vouch for these specific sellers:

https://www.amazon.com/uxcell-Pneumatic-Speed-Control-Fitting/dp/B01AUQ3668