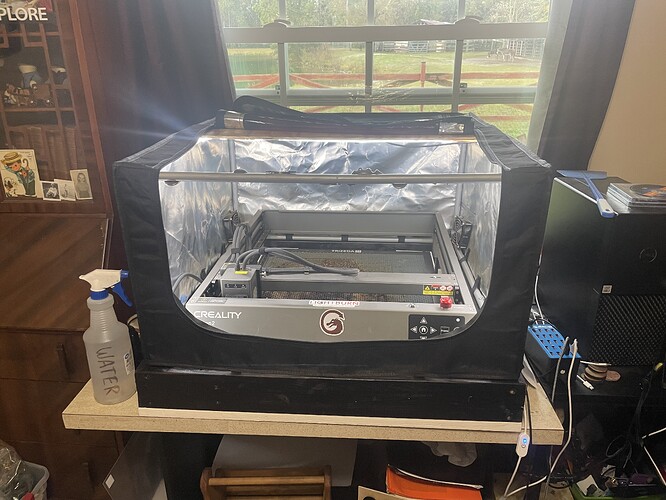

I recently purchased a Creality rotary unit for my engraver. After searching this forum, I was able to get it working pretty well. The problem was that I had to install feet extensions to fit the rotary under the laser. Having a 3D printer I decided to design a platform that is permanently mounted to the table to raise up the honey comb to the original distance from the laser. It also had to make it easy to remove the honey comb and put it back in easily. With this setup, in less than a minute I can switch it to rotary and then back to honeycomb. In order to keep the camera at the proper height I did have to make a 2x4base to raise up the cover to the original height.

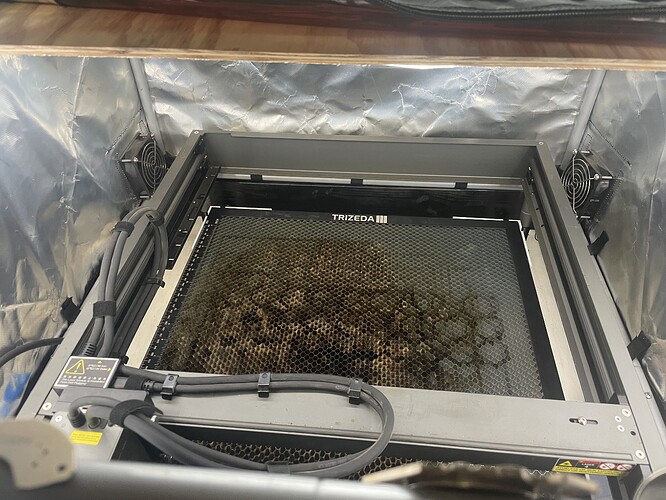

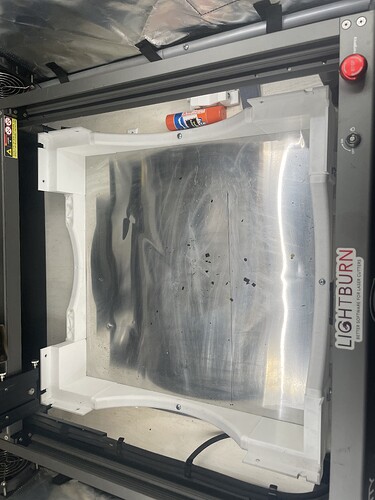

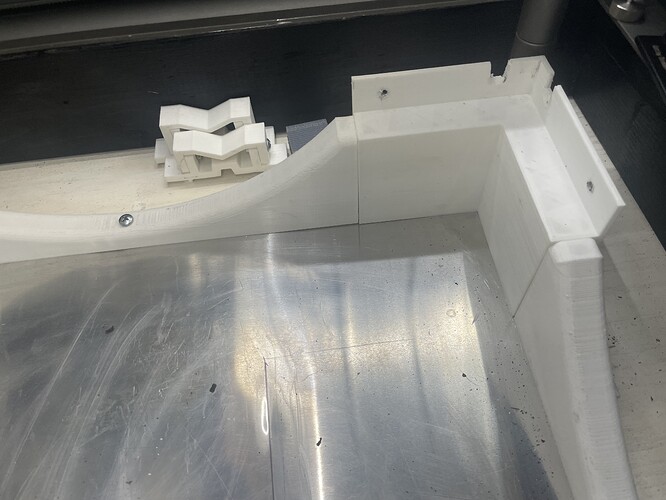

The first one shows the honey comb with everything complete. The second one shows the inside honeycomb setup. The third is the 3D printed honeycomb base.

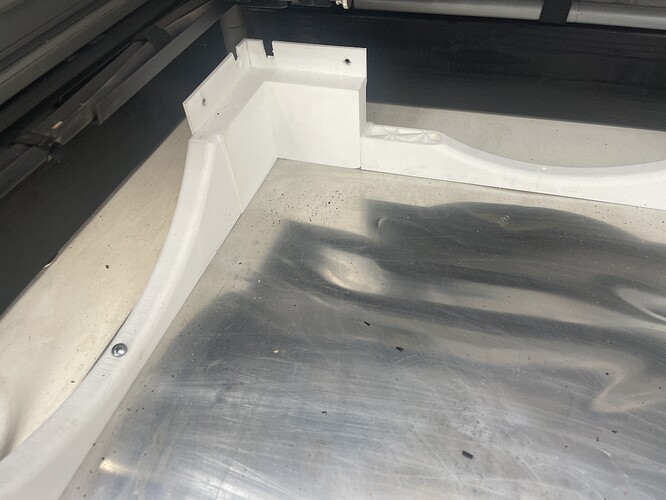

The next 2 are closeups of the base. Notice that I had to cut notches out for the rivets to be able to easily slide the honeycomb in and out. The third picture shows the rotary unit in place. I added a line to the bottom plate to be able to quickly place it in the right place.

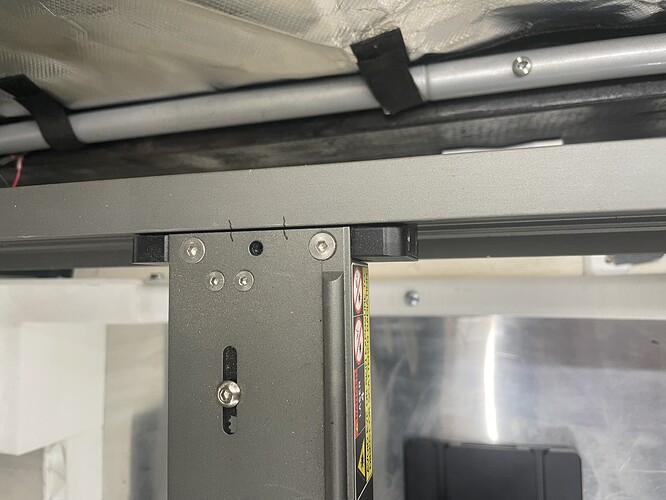

I also added 2little marks on the Y axis beam and the frame so that it is properly aligned with the rotary. The last pictures are supports for glasses/containers that are too long for the end support. If you have a 3D printer, PM me and I’ll email you any or all of the designs. I can also print any of the designs.