Arghhhhh I have just put in my air assist and now I am getting this mis alignment between the cut and the engrave does anyone know why I am getting this? Everything seems to have shifted the the right!

i would say 90% certain your issue is loose y belts

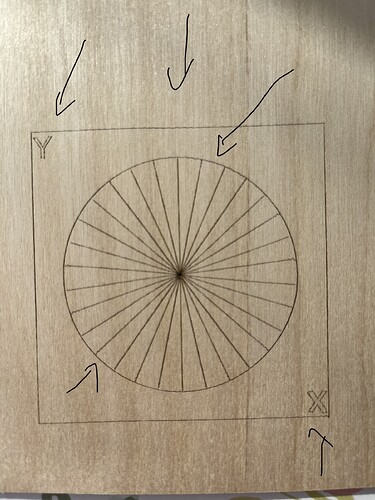

try this test file and send results please

Dot Test with Angle.lbrn (46.3 KB)

Thankyou will do that

When I first installed my air assist on my diode laser, I also had strange problems. It turned out that the air hose that I installed was too tight and prevented free movement of my X axis.

Hi

I think it might have been the focus I have fiddled about with it and it seems to have improved but now I am getting smudging around the engraved parts ![]() feels like there is always something and I am not quite getting there!

feels like there is always something and I am not quite getting there!

It’s hard to judge from this picture.

Did you manage to do the test that @gilaraujo recommended?

your pattern is not yet correct YOu have some looseness in belts still

Please run my pattern

Hi

I ran the test there are some wriggles!

Can you see from the picture? It’s taken me a few days as I have three small children so not always easy!

Do you have any specifics that I could look at and tweak?

Thankyou for your help

Nicola

when you hold the laser head and apply rotation up and down, do you feel there is any slack between the wheels and the frame

The S9 tends to have the laser module very LOW , almost like a pendulum

This causes some harmonic vibrations on the frame

I woul sugest you revise the eccentric nuts on the X axis wheels and also make sure the wiring is well cable tied to the frame as per manufacturer recomendations

The wiggles are not impossible to fully remove but yours seem overly expressed

maybe take a picture of the machine as a whole something might give some clues

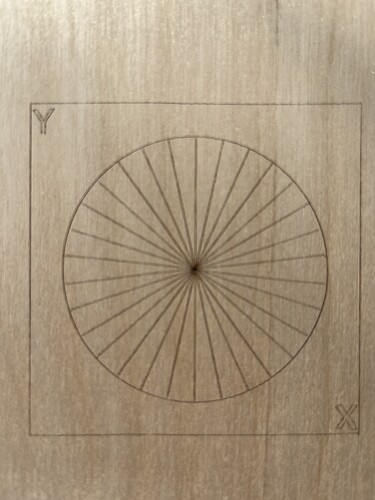

Thankyou for the information I was getting a bit deflated! Played with the eccentric nut and this is the improvement. Nicola

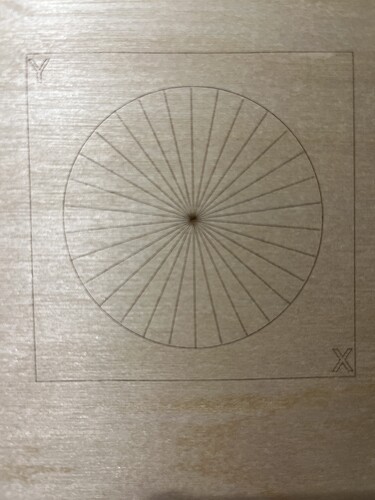

Def much much better and it’s been doing great for the last few days!

This is as perfect as it could be!

I would revisit tension in a week or so if you are going to engrave a lot as belts will settle in a bit

But i wouldnt touch it much for now

Thankyou for your help

Good Evening,

I’m still new to the forum and hoping that someone might be able to provide me with some advice to help with the issue that I am having.

I am running an ACMER P2 33W diode laser.

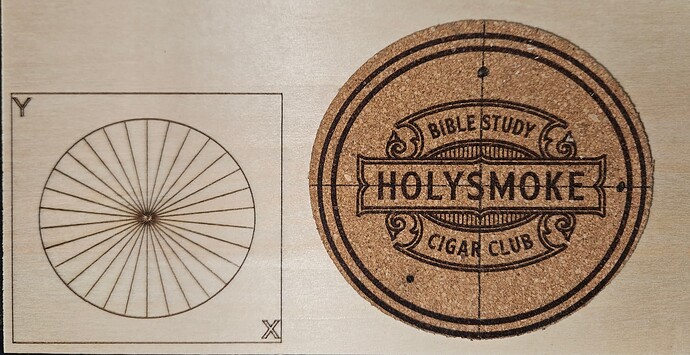

I have created a jig (3mm Plywood) for 7 cork coasters (95mm X 4.5mm) to be created in bulk.

The jig has been secured and the laser position was not moved.

After removing the waste wood from the jig (without moving jig or laser) I place the cork coaster in the jig opening (leaving ~1mm gap to jig)

When I try run a test to confirm alignment I get results on the cork as seen in the right side of the image.

I get similar results when I use 3mm Plywood blanks in the same jig openings.

In an effort to find a solution I stumbled across this thread and ran the recommended DOT TEST WITH ANGLE.lbrn file and received the results that can be seen in the left side of the image.

Would anyone here have any suggestions / recommendations?

My thanks to one and all in advance for your time and consideration in this matter.

I anxiously hope to hear your thoughts soon.

Be Blessed,

WD Wade

WDWade@TheNubber.com

Seems to me the issue now is

a) you have rotary mode enabled - and forgot to turn it off

b) you edited $100 $101

In console type $$ press enter and read the 100 101 values

Laser Tools > rotary Wizard - Make sure Rotary Enabled is not turned on.

Thank you for your reply - I REALLY APPRECIATE the guidance.

I do use the rotary function quite often and was fairly certain that it was not turned on.

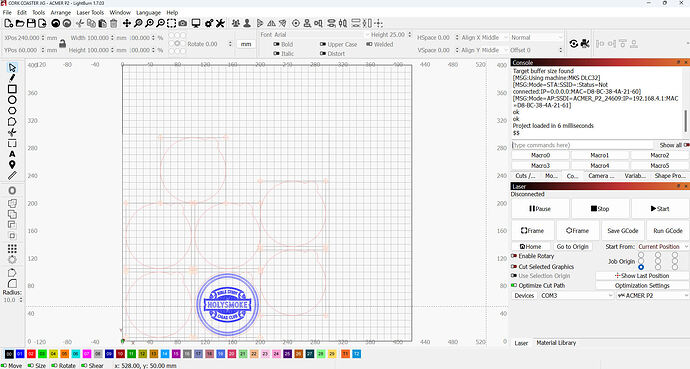

That said, I verified that the rotary is not enabled (as seen in attached screenshot).

I tried the $$ command in the console and did not receive any values back (as seen in attached screenshot).