hello, I am trying to engrave a glass cup with a thickness of 2.7 mm. I have tried engraving at 10mm/s with 25% power and 100mm/s with 40% power. both have caused the glass to crack. what tips should I know?

What type of laser? CO2 or diode? what power?

Since your controller is ruida, I 'll assume for now it’s CO2.

If that’s the case then you’re WAY overpowering the glass. Try lower power, much higher speed.

Engraving with an 80W machine I use around 300mm/s & maybe 17-20% power. Depends a lot on the glass.

Edit: actually I run as much as 400mm/s on a lot of glass, 300 is at the very low end.

Thanks, I will try that on monday!

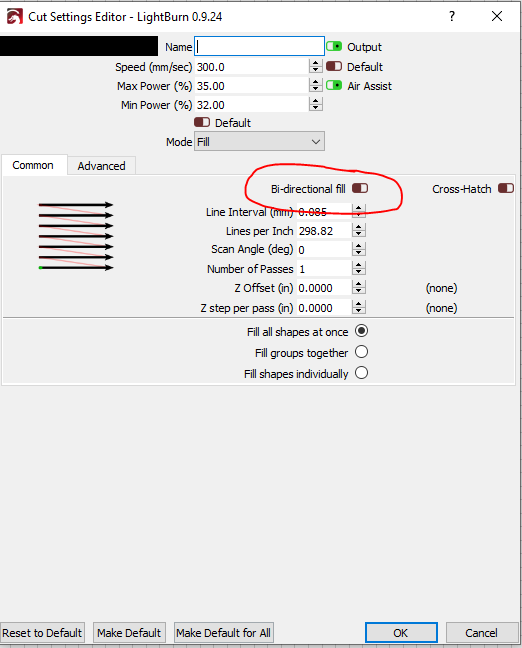

I agree with Hank on using faster speeds. I usually run around 300-350 mm/s on glass. The other tip is to turn off Bi-Directional Fill. This will increase the time to engrave, but it allows the glass a bit of time between burns to cool, as it only engraves in one direction, then returns the head to the start to engrave the next line. I’ve engraved some fairly thin glass this way and have always had good luck. I usually always put a bit of liquid dish soap on the area as well to help a bit more with cooling.

Also air assist helps cool the glass.

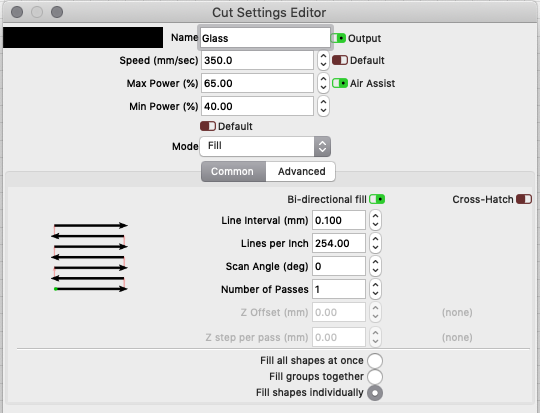

I use a lot of reclaimed glass. 3mm-5mm +

Settings for Reci running at 100W

Bo, your speed and interval seem similar to what I use, but you use a lot more power. I have much better luck with less.

Do you put any kind of coating or masking on your glass when you etch?

Nope. Run it hot and fast. Old glass, from greenhouses and old houses, old mirrors, etc.

Hmm. Interesting. Proof again that there’s no “universal setting” and everyone just needs to experiment to find what works best.

If the glass is flat I use a larger tile underneath to absorb the warmth.

the problem is that I cannot go past 50% power or I will melt the outlet

Melt what outlet? Sounds like you need an electrician.

What’s the power of your laser?

I heared about people using wet napkins when engraving glass

the laser is 60 watts. we already had an electrition come and fix the outlet, we just prefer to not go above 50% due to the fact that we already melted the outlet.

The current drain is about the same as a 60W lightbulb

If you ‘melted’ an electrical outlet, you have much bigger problems that you need to address

Thinking that not driving your laser more than 50% is the solution is just bizarre

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.