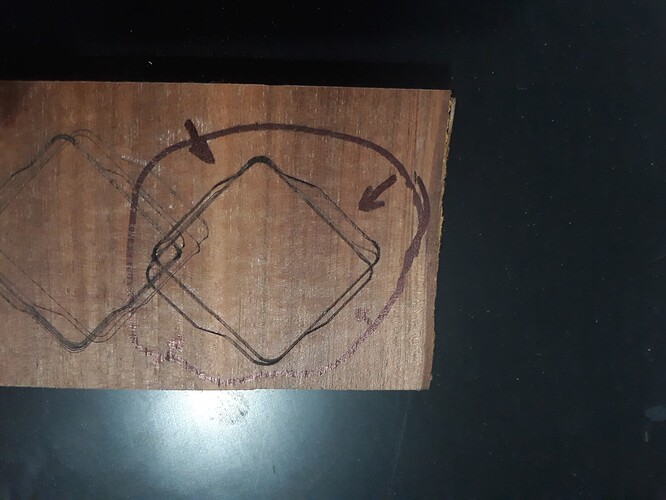

I engraved a 45degree square and the lines of the Engraved box are not straight. This happened after the engraver slammed into the side of the frame and I had to power off the machine to stop any damage.

The opposite lines of the engraved square are mirrored images of the opposite sides. Would I have caused any mechanical damage to the xTool Engraver that would result in this very consistent mirrored offset image rather than the expected straight lines?

Rennie

Can you post a photo of what you’re seeing? Also, where did the crash occur and in which direction was the laser head moving during the crash?

The image is circled and the arrows indicate the deviations from the actual drawn image.

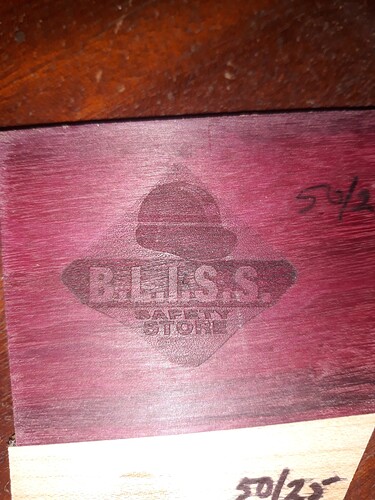

Actually in a previous item the engraving was not donne correctly. This is before the crash.

The laser head was moving towards the control module and crashed on the rail close to it.

But l now believe that the crash may not have anything to do with the engraving problem as a previous engraving was not done properly. I will upload a picture of that one

The red wood engraving was before the crash hbut it was not reproduced accurately by the Engraver. The brown wood was done after the crash and was even worse

Is that meant to be a square? With square corners?

And is the orientation of the picture the orientation in which it was engraved?

This is definitely something mechanical. If I had to guess I would say that the laser head assembly is only very loosely secured to the gantry. So if you attempt to lift or push and pull the laser head assembly I suspect there will be a lot of movement, as in not tightly secured to the gantry. So when the laser is changing directions the laser head is flopping around behind the movement. I’m not certain about the D1 but I assume it has wheels that ride on the groove of the gantry. If so, use the eccentric nut behind the wheel to close any gap between the wheel and gantry. Do this for all wheels.

This might also be loose pinions on the stepper shaft. I suggest doing a full mechanical review of the machine and looking for anywhere with looseness or backlash.

It is a square rotated 45 degrees with curved corners. What is interested is that the opposite sides of the square are mirror images of the opposite sides which should be straight lines. I agree it is most likely mechanical and I did plan to do a full check.

Thanks. Will provide feedback after doing the mechanical check.

I assumed this was because the laser head was flopping in the opposite direction for that movement. This is pretty severe though so you would notice pretty extreme movement… as-in the laser assembly would be wobbly to the touch. It could be something more subtle where it’s only moving along a single axis so it’s less obvious.

The problem was the cross beam with the laser head. It was a bit wobbly. It was removed and reassembled and the problem is no more.

Thanks for the quick response and suggestions.

Figured as much. Glad you got it.