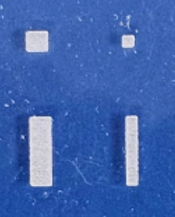

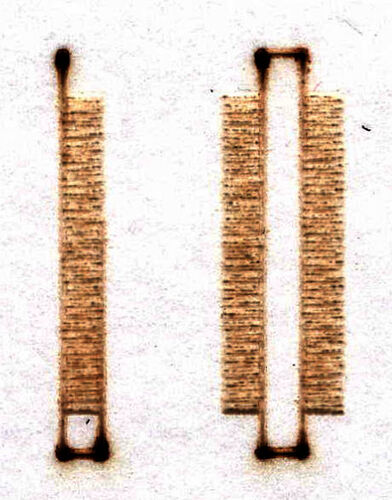

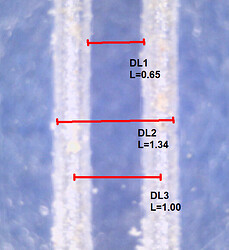

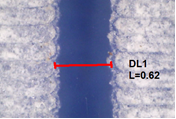

When I was Invert engraving on slate, I noticed that the areas I didn’t want engraved and to remain black got significantly smaller. In some cases, I can compensate by enlarging the area that I want to remain unengraved. Or even lowering the DPI if it’s a photo. Since I thought it was perhaps the substance I was engraving on, I explored what was happening with acrylic. So, let’s say you have a box, and it’s set to fill. The engraving will take place where you have the box and nothing outside of the box. Here’s an example of the filled box. (Clear acrylic placed on a blue background). A 1 and 2mm rectangle and square are shown here.

Now, let’s say you surround this box with another box on the same fill layer. You will get an engraving that excludes the box. An inverse engraving.

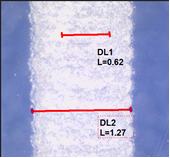

Now if you measure (I use a measuring microscope), the engraving width, the 1mm normal engraving is wider than 1mm while the inverted print the unengraved part is narrower than 1mm by a significant amount. You can see the difference in this example visually. Where this makes a difference is when lasering slate. The parts you want to come out dark are a lot smaller and sometimes disappear. I end up manually adjusting the vectors if using vector graphics or lowering the dpi if it’s a bitmap.

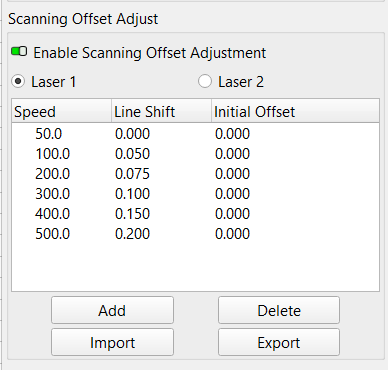

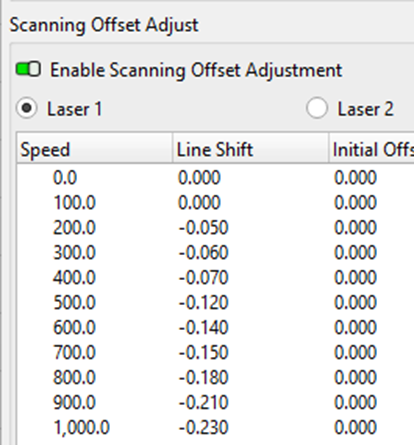

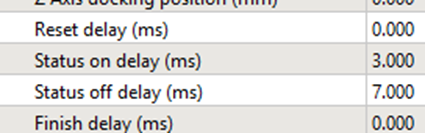

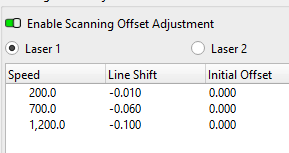

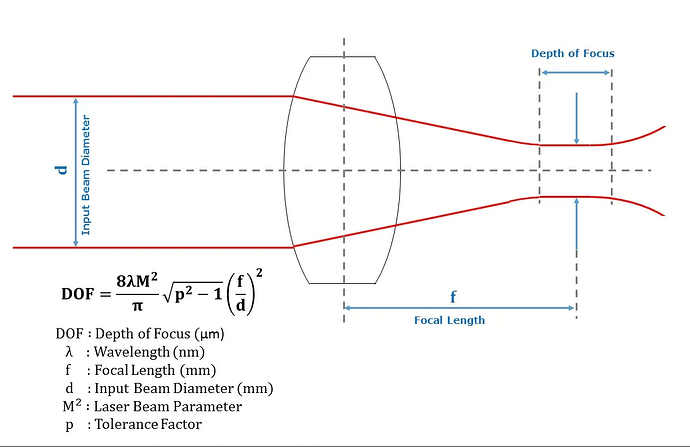

On my Nova 14 I adjusted my scanning offsets from 100 to 1000mm/s in steps of 100, tried slower speeds, and used single direction. Yet, the results are the same. The filled engraving comes out larger, while the inverse engraving comes out smaller than the box drawn. It’s not due to scanning offset issues, speed or bi-directional printing. I’ve also checked my axis calibration.

Don’t know why or if it’s adjustable. On a CNC router, I would have the ability to choose to cut Outside, On or Inside the line. Don’t think that’s an option here. But, if you have an explanation, that will expand my understanding.

Using 130Watt CO2 Aeon Nova 14S, Windows 11, Ruida Controller