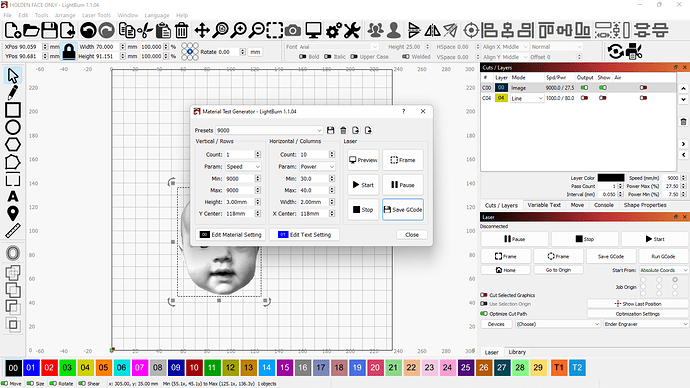

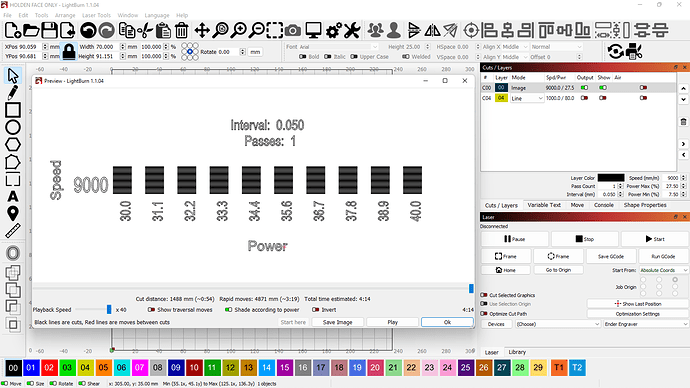

When I run a Material Test at 9000 it goes 9000. When I engrave a photo at 9000 it is much slower and burns my material. I have everything set to 9000 but it is moving slowly.

What units are you talking about? And are you certain the units for the material test match your cut settings?

Screenshots are helpful to understand what you’re seeing.

also when i change the mm/min to mm/s in device settings everything changes the same in the software. Just when I print it is not going 9000 mm/min

Printing off the machines SD card and not connected to my PC.

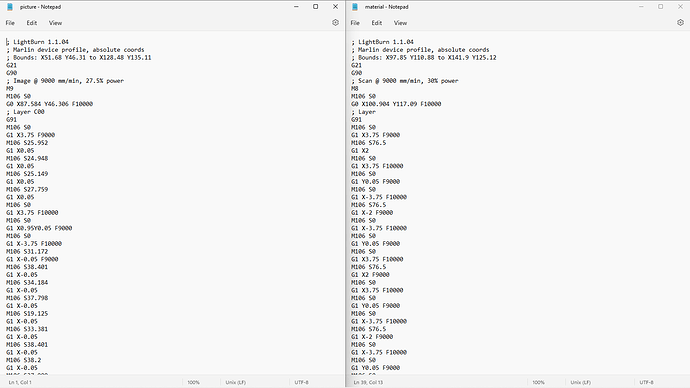

Can you save the gcode for the material test and the normal burn and upload here?

Also, it’s likely that you’re not ever actually getting to 9,000 mm/min in either burn unless you have an exceptionally fast machine. You list Creality in your profile but what specific machine are you running? In that case, it’s just a matter of determining which run is not behaving correctly.

My engraver is a mix of spare parts, mostly Creality. It is a dedicated Laser engraver now. It can easily move at 12,000 mm/min. I often print on my other 3D printers at 200mm/s which is 12,000mm/min. Do you need the full G-code?

Can you actually notice visually a speed difference between let’s say 11,000 mm/min and 12,000 mm/min?

The g-code is interesting. Both are clearly asking your machine to run at 9000 mm/min. Looks like traversal moves might be set to 10,000 mm/min.

I don’t know which side is which. I assume the right is the material test and the left is what you’re trying to burn. Is it possible that the density of instructions for your regular burn is high enough that your machine is struggling to process the data? Image burns, especially grayscale are extremely instruction dense. From looking at your board I think that’s based on an 8-bit ATMEGA2560. These are known to be bottlenecks for top speed. But I’m not sure if this could account for what you’re seeing in your particular case.

How much slower is the job you’re trying to run? Perhaps try running a simpler job and see if speed is recovered.

Correct, the Picture is left and Material is right. They are labeled at the top. It is noticeably slower. The mainboard has a 32bit CPU, but it is not a ST32 it is a CLONE GD32. Creality changed CPUs and did not tell anyone, they claim a ST chip shortage. I was thinking like you said the Board is struggling but it is slow right from the start. I did notice air assist is on in the material test gcode and not in the picture. I will try and turn air assist on, you never know. I think you are right and it is the longer code?? I will do some test and report back. Thank you!

GD32 should be quite speedy but it’s possible you’re still seeing a processing bottleneck. I’m not accustomed to engraving at those speeds and certainly not with images.

You could attempt to test at dramatically slower speeds… let’s say 3000 mm/min to see if the speeds are the same. Then test gradually faster until you see it diverge. Then that would fairly conclude that it’s a hardware limitation.

I did a test. Material test with a 30mm block and a small portion of the photo. I uploaded video to YouTube.

https://youtu.be/U7-60E9_5o8

sorry the Material Test is upside down but I see a big difference? Do you see a speed difference?

Definitely. I’d say roughly 1.5x faster.

It is the creality mainboard. Junk. The longer Gcode is slowing the system down.

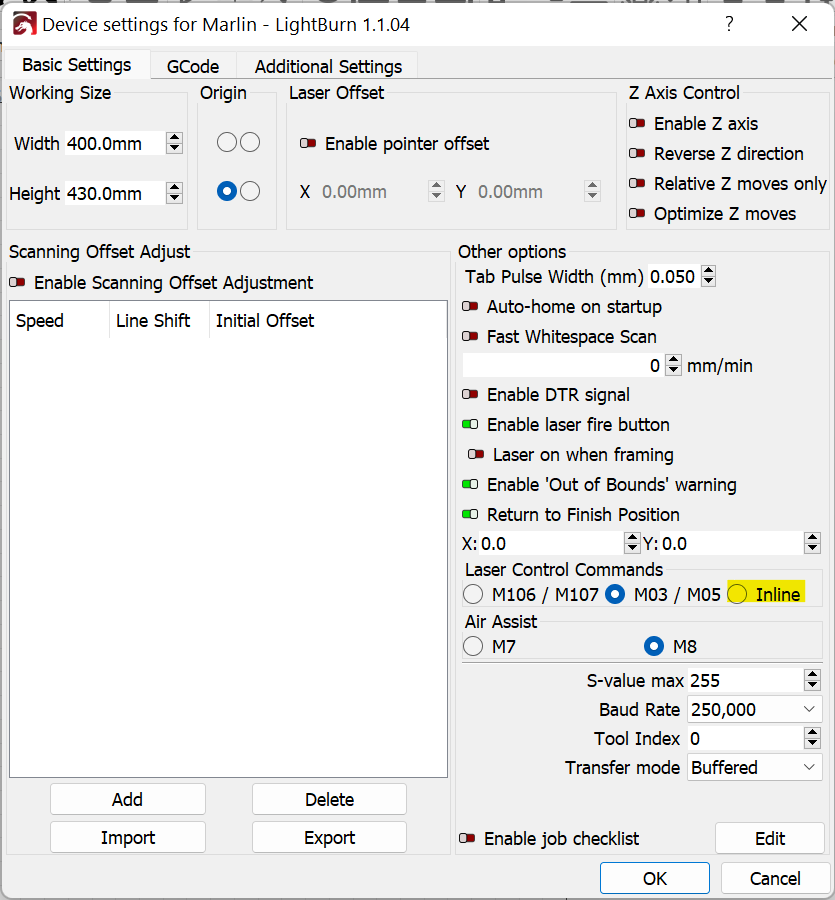

You should perhaps try “Inline” for laser control. I think I saw that this could potentially be faster/smoother for Marlin.

In-line? Not sure what you mean

Check here for information on inline mode:

Laser/Spindle Configuration (2.0.9.x) | Marlin Firmware (marlinfw.org)

I have a good PWM signal. I am using M106 M107. I will read up on in-line.

That’s only 150mm/sec, which is not particularly fast. I regularly engrave at 500mm/sec without issue on my OmTech.

tbh I don’t understand why you’d work in mm/minute instead of mm/second in the first place though.

You may have missed it but @vender is using a diode laser on a Creality 3D printer based machine. The mass of the laser module assembly makes acceleration much more difficult as compared to a CO2 laser. 9,000 mm/min (150 mm/s) in this case would be quite fast unless very specific provisions have been made to accommodate this, especially on a smaller bed where top speed is never achieved.

Because of the slower acceleration/speed for high mass laser heads the numeric values work better in mm/min as compared to mm/sec. For example, ranges of speed of 100-500 mm/min could be a perfectly normal speed for a diode operation. Would you want to really be specifying that in terms of 1.666 mm/s - 8.333 mm/s?