I got my laser engraver just on week ago, therefore my first steps where to do material tests.

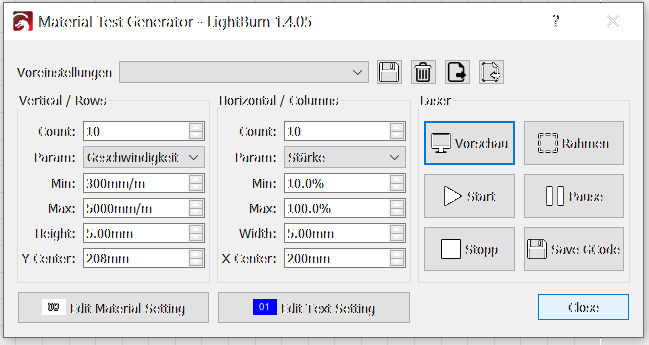

With the default settings like this

The engraver will start with the slowest (300mm/m) row.

I had some issues, because sometimes the material was nearly burning when it reaches a certain power amount. The sample was then useless.

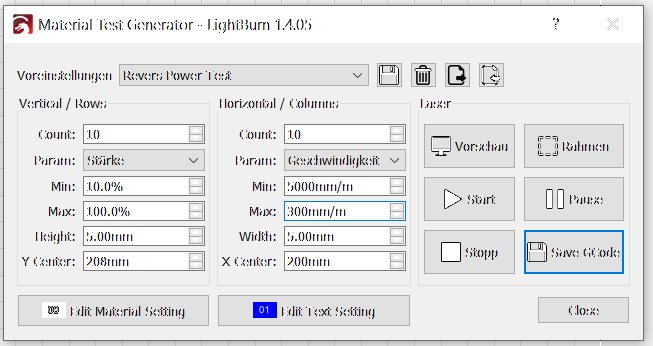

My solution was to change the generator settings like this:

This will start the 10% power row, with the fastest speed first, slowing down - and than increasing the power row by row.

It is easy to stop the process when the cuts where successful.

It would be even better if the order in which the boxes are executed is selected by the amount of energy applied to a certain spot (using the result of Power/Speed).

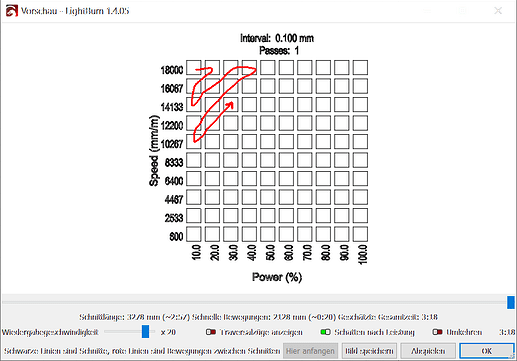

The expected result should look nearly like this:

This will help finding the the best values, even when the processing has to be stopped. Because al boxes of interesst would already have finished.

Is this already possible?

If not, this would be a very nice improvement.

Thanks a lot.

Joe