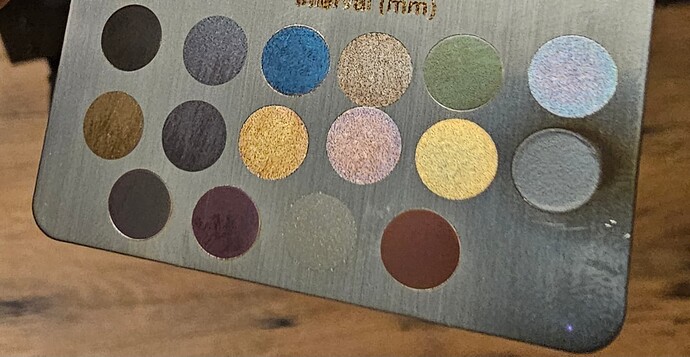

I am using a 60w jpt mopa source laser from Haotian laser. So far i have been having decent success with replicating colors. Blues, gold, “white”, black, and green are fairly easy to replicate. I am having difficulties finding a high quality red, but I’m getting there. I mainly use my 210x210 lens for color marking.

Would others like to share their colored projects? I have been doing some thin (whatever color) line flag coins on Swissbui stainless coin blanks lately that have been very popular at work.

I am curious about long term durability. Will this annealing color change persist indefinitely? I’ve been keeping this flag themed steel business card wet to see if it would rust or corrode and so far so good, it hasn’t had any issues and is about a month old.

I’m mostly happy with the colors I’m getting (although I feel a better red is out there… any reds from small material grids i have tried seem to end up brown when scaled up). I do see some consistent issues with colors sometimes bleeding into small structures- in both pictures you can see some intrusions of the surrounding colors into the stars. Additionally, some very small structures may not “fill” with a color. I’m not sure of the cause, but many colors show a line on their test grids and that seems to show it isnt appropriate for filling small areas. I will try and get a picture of that later.