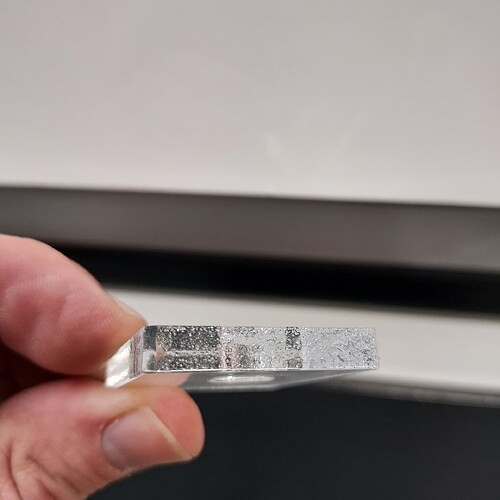

Hello All, I have been cutting acrylic for about 7 years now, mostly cast. I have a job that requires extruded and the edges are less than satisfactory. I have a new laser, similar to my old one 150w. I used to cut this stuff and it would have a nice flame polished edge. Any advice on why this is happening?

That’s exactly what I have come to expect when cutting extruded acrylic. It misbehaves in other ways as well - sanding and glueing with solvent cement often results in cracks propagating from the cut edge. I’m surprised that you have ever had any success with it. It is much more sensitive to high temperatures than cast acrylic - perhaps you can increase the air assist flow rate to reduce what looks like overheating, or maybe take more passes at lower power maybe?? Or just use cast acrylic.

1 Like