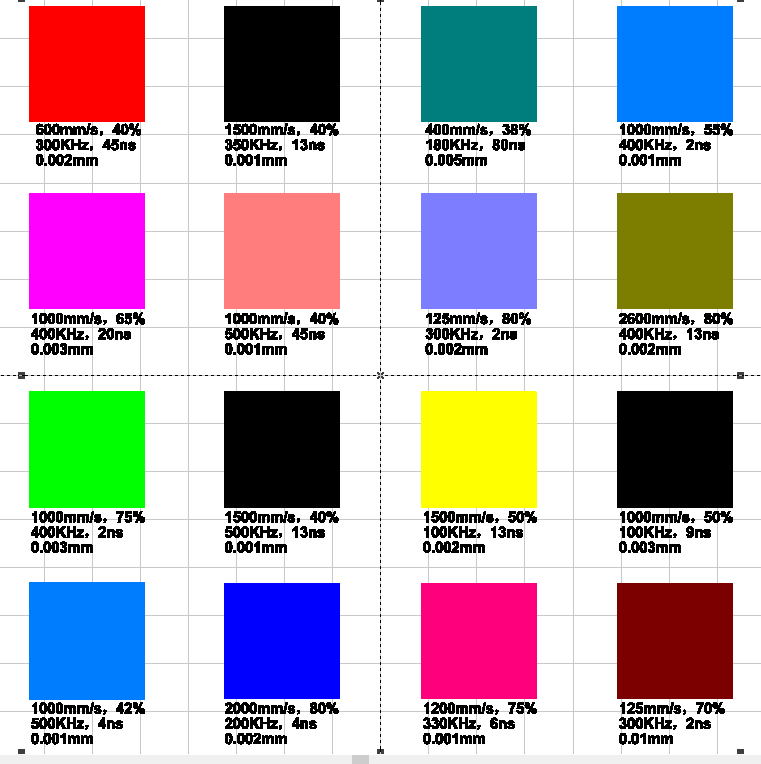

The ezcad color settings for my 60w M7 laser don’t work in LB. Here are the settings that came with my laser

What do you mean? From where…?

I have a similar machine, there wasn’t any settings…

There is no mention of the thickness or the type of stainless or is it titanium?

What are you doing with this?

![]()

Did you try all of those before the upgrade to LB? Colors are tough, very specific to material grade, surface, iron content. Stainless and titanium as noted above are about the only thing you will get most colors with, although I have seen blue on non\stainless steel. Lots and lots of experimenting.

These settings came with my Laser using a 174mm lens, focus 30cm. The colors work with ezcad2 on stainless steel.

If the machine is setup correctly is should not matter what software package you use…

They both tell the machine the same thing…

Can you elaborate on what the difference is?

Photo?

![]()

the numbers you use for lens and focus don’t match typical galvo lenses There is an F-Theta number on the lens collar/ ring, what is it on your 174 lens? Do you have any photos of your color tests from ezcad?

The lens has F-Theta Ronar, SL-1064-174-254G, SL190216620. Don’t have any old color test.

The coverage on these are 174mmX174mm… some of the manufacturers stick that into the part number… 1064 is the frequency, 174 is the coverage, 245 is the focal length and G is maximum power < 100W…

Above 100W the price goes up by about 8 times. ![]()

Are you getting the full 174mm^2 coverage?

![]()

Are these the maximum settings? Is the 245 focal length in mm or cm? Guessing 24.5 cm.

Are what the maximum settings?

All of this stuff is pretty much in mm… a 245cm focal length would be 2.45 meters. That’s a long lens…

![]()

Yes on the MM. The focal length starts somewhere between the mirrors and the back side of the lens, so your distance from the front of the lens will be a little less. Start higher then the 245 and slowly lower the laser while running continuous on a test piece, listen for the loudest burn. That measurement will be your “In Focus” setting. For colors and Black on SS I typically defocus a few mm (Up) to increase the spot size and reduce the power density. Start around 4mm and adjust from there. There is such a variety of stainless, both in alloy composition and surface finish, as well as thickness, getting good color will take a bit of experimenting. Jumping into a new laser and heading straight for colors expect there will be quite a learning curve.

Have you gone through the LMA’s Crash Course for LB? Valuable information even if you have some experience.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.