How stable is the current meter you have? Most digital meters don’t do well with measuring a lasers current… It really depends on how it’s wired up and with these, I’ve no idea.

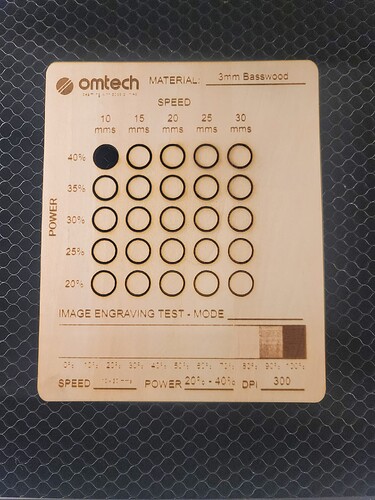

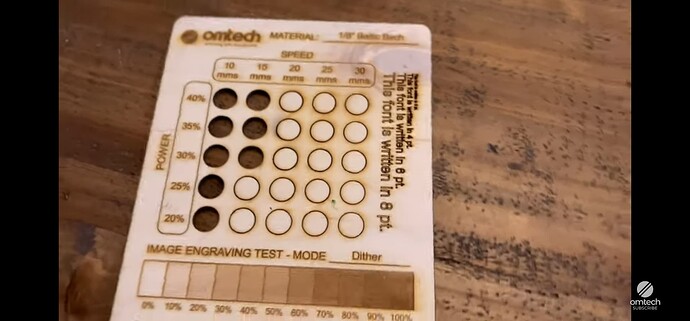

The idea of these is to be able to say I want 50% power in the layer and get 50% power from the device, led, co2, fiber… etc.

If the equipment isn’t set up properly you end up in your situation. When you ask for 70% and get 100% out. Ending up with only a 30% range of step adjustment. I.E. 40% to 70%

This, I’m sure also leads to confusion on effective speed and power settings.

I’d suggest not running your machine at 100% power in the layer. The current supplied is only limited by the lps (laser power supply/high voltage). Which is clearly supplying too much.

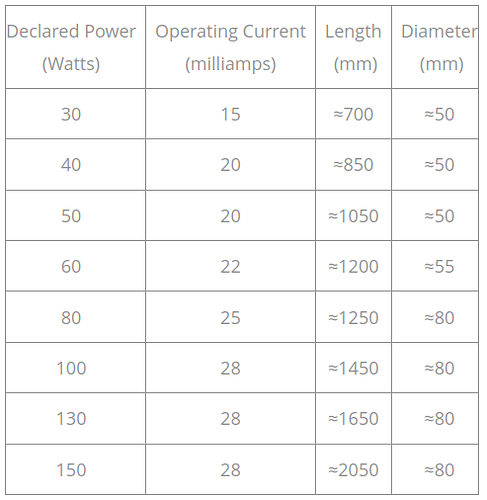

How much power and equally how much current that can be created/used with a tube laser is basically it’s length. Tubes > ~60W increase diameter, but all tubes relate length to power.

These are considered 100% operational values or working values. It is not absolute, but ball park…

Some manufacturers give you the don’t exceed maximum, which causes irreversible tube gas damage. So you have to know what they are referring.

I believe, as do others, that once you top out with current, like the 26mA he is running, is doing permanent damage to the tubes gas.

You could have gotten about the same results as setting it to 50% power and measuring the current… That would be half of 100%… at least close enough. Without any risk of damage.

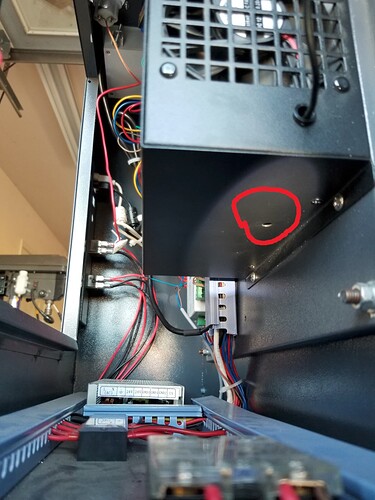

This is how my Ruida → lps is setup. I know the 100% current allowed for designed output. I know the Ruida will generate 50% pwm which will limit it’s output to 50% power on the lps. Adjusting the lps current limiting to 50% of the desired limit will align the percentage asked for to be more accurate…

Your control is severely limited to a range of only 30% steps for power control… This really limits what you can do… or even attempt… If you could adjust your lps, it would restore over triple the range available to you…

This really limits what you can do… or even attempt… If you could adjust your lps, it would restore over triple the range available to you…

There are settings within the Ruida where you can specify what it the upper/lower pwm limits. These will prevent you from going above or below those limits.

Can you even get to the lps on your machine? On mine you need to be a contortionist.

Does any of this make sense?

We’re luck these things will take a lot of abuse…

Russ Sadler has many videos, most on using RDWorks that comes with the Ruida controller on most of these Chinese machines… I like the way he teaches and gives very good examples of how lots of this stuff works…

Good luck