Hi everyone! I’m Morrigan, really new to the laser scene so bear with me and any of my silly questions or poor lack of laser lingo. I’m a quick study but I’m struggling a little bit and I’m hoping all you gurus out there can help me out in this journey into laser cutting and engraving!

To start, my boyfriend and I are huge into gaming and making our own stuff. We have 3D printers (both FDM and SLA). We make our own stickers. Painting miniatures… the whole shebang. Its a passion of ours.

Well! We finally took the plunge into engraving as we genuinely wanted to start making our own game tokens, especially for games that we enjoy that don’t have them out there on the internet already. That’s what has me here and what I’m reaching out about.

So far my journey as been a little frustrating and a bit of a struggle. I will relay my struggles and some things that I have already found a resolution for.

Type of Laser that I have:

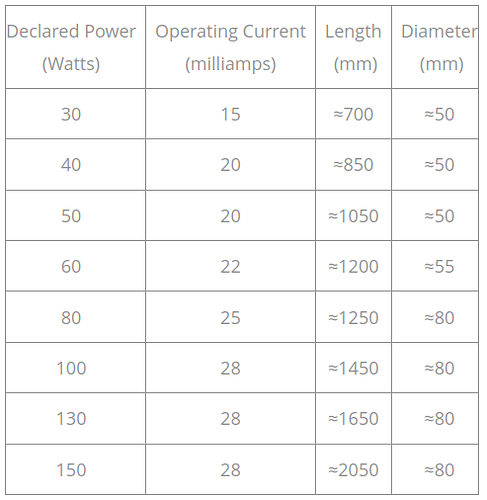

Omtech Polar 40W No upgrades to lenses or mirrors, no console

So far with all of my testing (and I’m unsure if this is normal or if I should be identifying a problem or anything). We tried on wood first but being that we want to work with acrylic that is what I’ll be talking about.

- The lowest power setting that will affect materials is 16. This is for anything. And this is even barely a light grazing. With this testing we determined 17-18 is where we see actual MA’s on the reader inside of the rig.

- LPI doesn’t seem to have a huge effect on engraving. We are getting what I would consider extreme grooved lines in our acrylic.

Tested speeds and powers have had a range of settings but these are a few that we have stuck closer to per settings found in videos and testing:- 150MM/s 18-20 power 300LPI (I have done 1 pass, 2 passes and 3 passes)

- 100MM/s 18-20 power 300LPI (I have done 1 pass, 2 passes and 3 passes)

- 500MM/s 50 power 400LPI (Omtech recommended settings per a document they sent us)

500MM/s 50power 400LPI (1 pass) with a 100MM/s 20max/15min offset spiral fill (1 pass) and a 500MM/s 50 400LPI final pass (I’ll be honest, so far this is the one that I find to have the few/least ridges.

Note: Per Omtech support I cannot use “crosshatch” in Lightburn. No reason was just flat told don’t do it.

- Cutting is smooth and beautiful, it is gorgeous once we figured out that leaving on tape is key to keep things from fogging (or burning the acrylic back in).

- Should there be an absurd amount of dust left behind when engraving? No matter what setting (air assist or not) it seems like the engraved portions are covered in a latent dust (this is whether there is tape or not). We have taken to using a toothbrush and water to clean it out but it just seems like there shouldn’t be that much when it should be blowing it all off.

Getting the ridges to be less pronounced is huge as it currently affects the overall final quality and finishing for the token so any help would be appreciated to get me in the better/right direction.

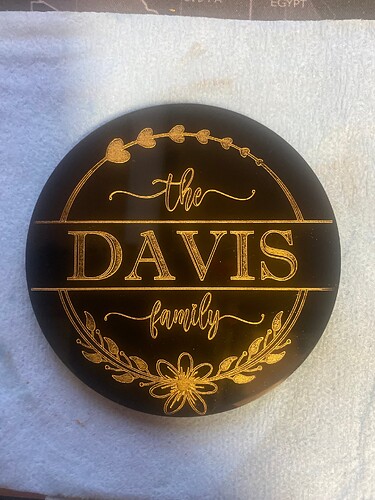

Next, I was curious what methods some people use to color fill areas? I’m looking for an effective way that isn’t super time consuming to color them and cover those ridges. I have been looking but haven’t found a lot of suggestions except to use acrylic ink or paint which I have been trying but I feel like I’m not quite getting the smooth appearing results that I see in some.

Its fabulous to meet you all. I look forward to being a contributor as I learn more and thanks for the help in advance!