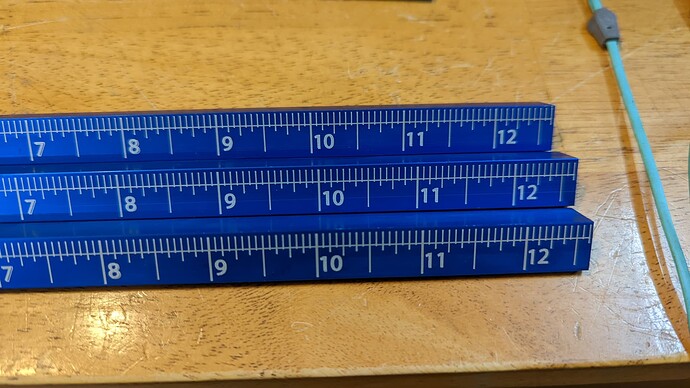

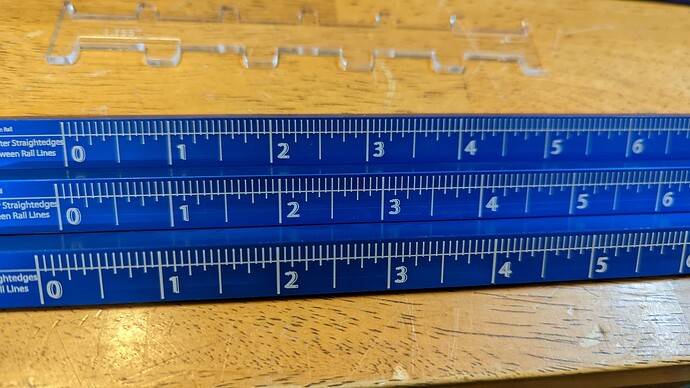

I am etching rulers into annodized aluminum. The rulers come out inconsistently, off by up to a few hundredths of an inch from one run to another. It seems to be a calibration issue because they are gradually out of sync across the ruler.

The belts are looking well tensioned to me and nothing has any wobble or give when I manually try to move the gantry and head while the machine is on.

More details: Lightburn is creating a path that first makes the smaller ruler marks for 8th and 16ths from right to left: each mark is a small narrow rectangle that I have set to Line with no fill. Then the larger lines for 1/4th, 1/2 and whole inches are etched from left to right. The smaller marks are dead on accurate. The larger marks begin accurately from the left, but are slightly too far apart so that by the time they get to the right side they are a couple hundredths too far to the right. So: calibration is correct when moving right to left, but appears to be off when moving left to right.

Secondly, the numbers on the ruler are etched with a fill and line setting, but the lines do not match the fill, also gradually from one side to the other (they start ok on the right, then get more and more out of sync toward the left) End result is about 1-2 hundredths off.

If this is a calibration or backlash issue, why does it only happen in one direction (Moving left to right vs. right to left?)

Speed and power were set to 50/15

I tested increasing the speed and power to 200/35. The first problem with the lines seemed to have been greatly improved by this change…

The second problem with the ruler number fills not matching their outlines did not improve.

My next step was to change ‘PWM Rising Edge Valid’ settings as per:

https://lightburnsoftware.github.io/NewDocs/ConfiguringRuida.html?fbclid=IwAR1xT_GTmrXugaAF_GtqookfsNGzpMns0FKL-EnCc3T48yTfSn_xptjaxBM

This did not change the results.

Next I did a scanning offset adjustment: Scanning Offset Adjustment - LightBurn Software Documentation

The fill appears to be more crisp, but the offset from the outline is now more clear and obvious. Still gradually increasing from right to left.

What could cause the machine to be progressively out of sync from one side to the other?