I have a new install of lightburn and a ruida controller.

When I set to fill, it burns either side of the image on the x axis.

Line 1: line

Line 2: fill

Line 3: fill+line

Line 4: offset fill

Any ideas why?

I have a new install of lightburn and a ruida controller.

When I set to fill, it burns either side of the image on the x axis.

Line 1: line

Line 2: fill

Line 3: fill+line

Line 4: offset fill

Any ideas why?

Hard to tell from the photo but you may be dealing with this:

Configuring a Ruida - LightBurn Software Documentation

Thank you, that fixed my inverted x controls, but not the double imaging.

It looks like its doing a fill either side of where its supposed to be.

Did you look at the “Fix Skewed Engraving” portion?

That’s what I’m thinking it might be.

But I’m reconsidering based on your description. This might be an issue of offset scanning. Try running a fill of a rectangle with line interval at 1 mm. What’s the behavior?

It looks like backlash, check for something loose on the X axis

Ooh,

I had a similar problem where tool head wasnt coming back to the correct x position when i used cough engravelab.

I had to turn off the machine when changing the settings from rotary to table and back, a lengthy, drawn out, painful procedure.

Thank you for the help.

The issue is now resolved

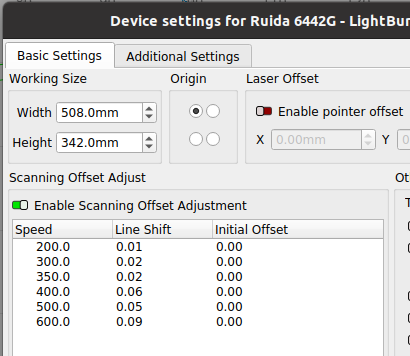

The numbers you have for backlash look extremely large to me… Here are a few of mine…

I think you have other configuration or hardware issues. It shouldn’t backlash 3mm.?

Maybe someone else can chip in on this…

![]()

Wouldnt surprise me at all. This machine has been a problem from day one.

Within the first 12 months:

Replaced x axis motor

Replaced x axis driver

Replaced table/rotary switch

Found bad solder joint in rotary

The feed through is in the wrong position and unuseable

No documentation available for engravelab 10

All I’ve been wanting to do is engrave pictures on glass.

The stupid thing is I used lightburn on the emblaser2 and never thought to try it on the co2.

Ill see if i can find anything like backlash settings in engravelab.

Ok, here are the ‘factory’ settings. They were set by the guy who installed the laser.

Backlash in it’s simplest terms comes from the clearance required for the parts to operate. I can’t imagine it taking a mm of clearance for it to work.

These belts are basically cam shaft belts and have very no ‘slack’, it’s hard to stretch or compress them. The drawback is they are really designed for a single direction, not back and forth… I wouldn’t think that would make for such large values.

Good luck

![]()

I had a word to the manufacturer, they told me its because they use servo motors, not stepper.

Great, my work with servos was decades ago. Sounds good since I don’t know any better…

![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.