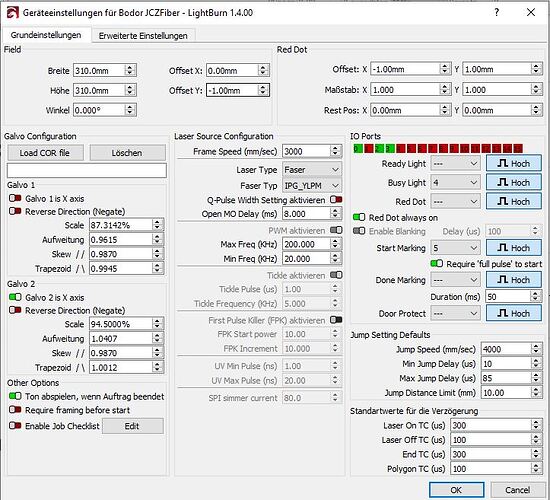

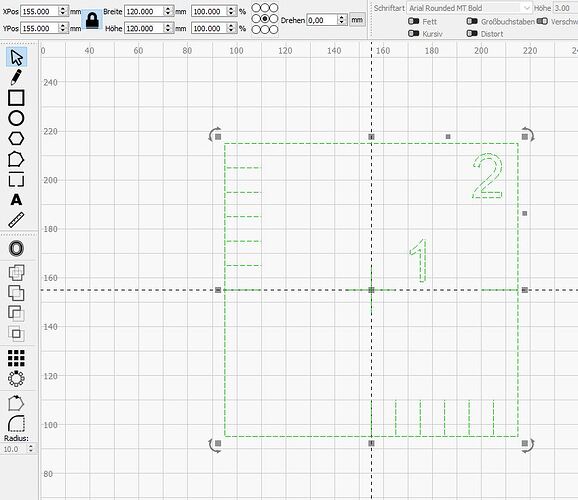

I guess, the title of this thread is self-explaining: how can I find (and align) the center on my Bodor Galvo laser machine?

Some informations on this issue: my workspace on the machine is 310x310mm large and the (formal) center is located at 155x155mm. But in fact, the (real) center has a slight offset to this (formal) center in X- and Y-direction, which I can only estimate (approx. 1mm in X-direction and approx. 0,5-0,8mm in Y-direction)

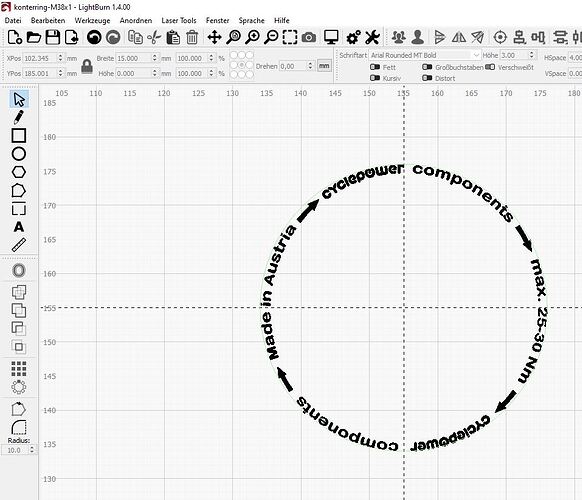

In fact, althought the offset seems to be low, this has an impact on engraving circular graphics. Especially, when this grafics/letters are small in height and the plane to be lasered is narrow.

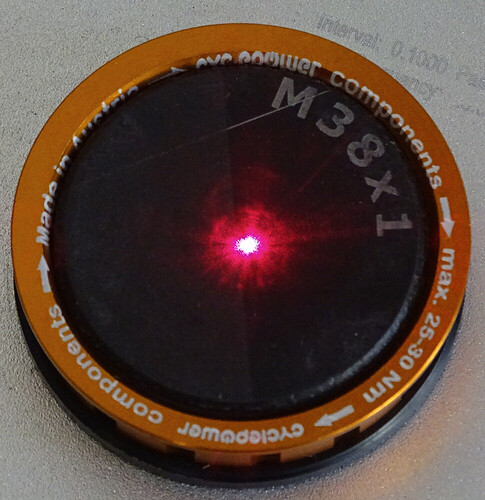

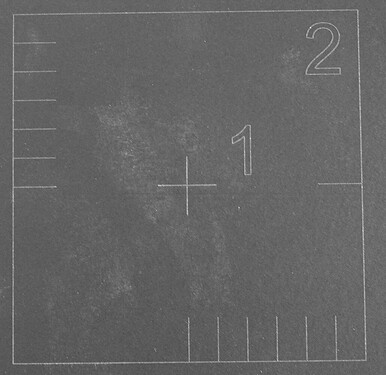

On the machine, I have a red laser pointer, which obviously marks the center of the galvo laser on the workspace. Here I can detect the offset.

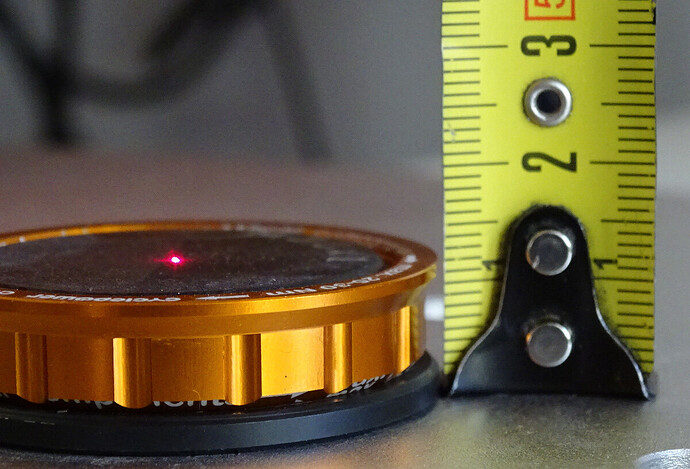

Another point is the focal lenght, which (obviously) has an impact on the roundness of the laser graphic. As written above, I often engrave circular grafics which are round in shape. I think, this is trivial, but the graphic on the part seems to have a deviation from the round shape and tend to get elliptical.

This problem is particularly evident and visually recognizable with graphics that are engraved on narrow surfaces. How can I ensure, that the round grafic (in Lightburn software) is applied fully round on the part? Which settings to I have to manipulate to solve this issue?