“Hard Homing” is not " G0X150Y0" but “$H”. You probably pressing “soft home” that is origin of work set by “$92”. Without completing Hard Homing Cycle this will be dependent on position at the moment of power up.

I’ve made special version for you for home switches located at upper right, where hard homing complete will set X=$130:Y=$131.

It is also possible that you did not flash your special version.

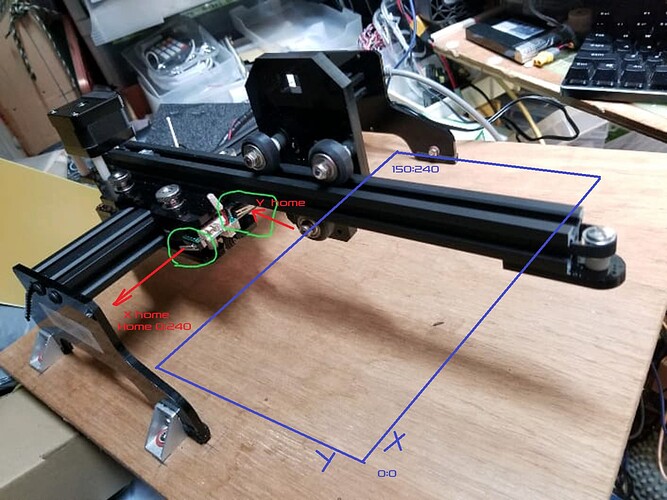

I’m getting more confused looking at your images. I was very certain that for T(X)frames - X-beam is on the back , so user can have free access to the work area.

On your images the best of my understanding home would be 0:240.

Or is it like on the following image?

Then I would understand that that home is on the upper right. But orientation is odd IMHO.

Do you know there are two different homes? "HARD"and “SOFT”? Soft usually used after setting “$92” as origin of work.

Please send through terminal command “$H”, then “$#” and post what you got back.

Also would be nice to get whole set of your GRBL settings.

It got to be trivial. It just a matter to get proper settings.