Okay, so I want to use the plans from Flite Test to make some models using foam board. I have done some experimenting and I am able to cut black foam board using my 5W diode laser. I am in the process of destroying more samples to do a material test on the black foamboard to see how to do the various bits and pieces. I’m getting a 10W diode laser operational, and I hope that I will be able to cut white foamboard with it. (Never even tried the 5W laser, every source I read says that it’s not great at it.)

I’m running into some problems.

-

The Flite Test plans do not seem to import cleanly into LightBurn. Some of the details just aren’t there at all, some images show up as a black square, some text isn’t there at all, either. Not really a big deal, I don’t really want most of that anyway, but it would be nice to have the option. Is there a way to get more complete information imported into LightBurn?

-

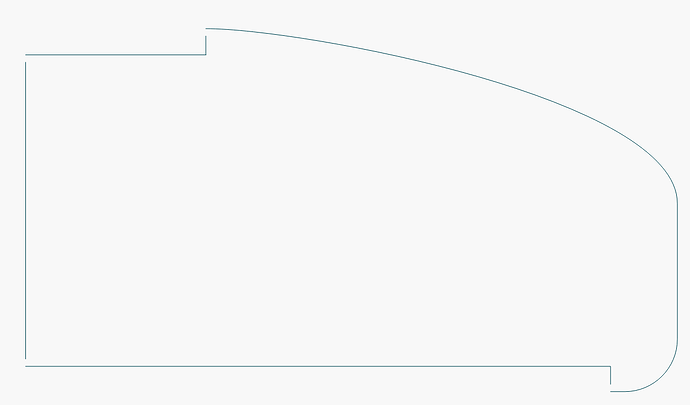

There are many different types of lines that need to be there. These are generally denoted by colour, and it seems the LightBurn almost gets this by putting them as different layers, but some things aren’t separated by layer, and I can’t see why. In this case, black lines are cuts, red lines are 50% score, green and cyan lines should just be surface marks. From the material test, I should be able to do all of these different kinds of cuts. I suppose that I need to be better able to manage the layers function. I admit that I’m not particularly good at this yet. Again, is there a way to maybe automate this a little?

-

The coloured lines are represented by dashed lines (so that they could be still discernable in a black and white print-out.) I will want these cut out. I can add a line in the appropriate layer, but it still seems to keep the original dashed line as well, and I’m afraid that these will end up in an additional pass. A double pass on what should be a 50% score will be a problem. (Hmmm. I suppose that what I could do is use the line draw on a new, unused layer, and turn off the output on the existing layers. The problem would be following curved lines…)

It just seemed to me to be far too convenient to just use the laser instead of going through the trouble of printing the plans and trying to transfer them over from printer paper to the foam board. Much more efficient to just get the laser to do as much of the job as possible. I suppose “last resort” might be to just get it to just at least mark the paper on the white foam board…

Anyway, if someone has some advise to share, I’d love the help!