I have the Falcon2 40w.

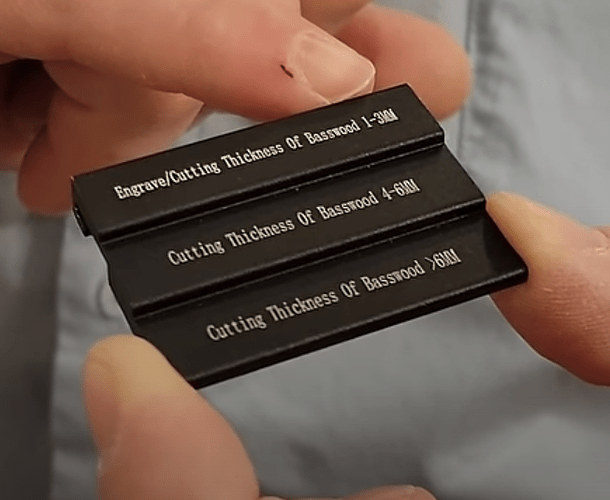

With my laser i have the focus block for Bass wood.

My question is, how go i focus the laser for say 6mm ceramic coasters etc, or is it trial and error?

There is no possible way we can tell. Start at the factory recommended focus.

It’s not really understood. Focus of a laser is the point of your optical system where there is the most effect/power. It does not change, no matter what material we use.

In some cases where the material is very thick, we try to bring the focal point further into the material, to handle the task and to compensate for the hourglass effect.

The focus of your ceramic coaster is on the top of the coster - with the same focus block you already have

Perfect, thank you.

I will try with different focal heights to get the best results.

Sorry if i have expressed me a little clunky,

The accompanying distance block gives you the distance you need, no more tests for engraving are needed.

No worries, i am new to this, and on the focas block it says bass wood, i was just wondering if anything different for different materials.

I will figure it out.

For some operations, changes in focus can be useful.

I find an advantage with a slight “de-focus” for some fill and line operations. When the laser has plenty of power for a fill on some materials (mainly wood for me), I can increase the spot size and perform the operation with a wider line interval at a proportionally higher power. Same concept for making wider lines without using offset passes.

It’s kind of like coloring in a shape or drawing a line with a marker versus a sharp pencil.

Will try that.

Ive been sticking to the rules, so to speak, afraid to go outside the lines…lol

You need a quick review of how lenses work. There are a ton of videos, but I’ll try to simplify it to how I use lenses.

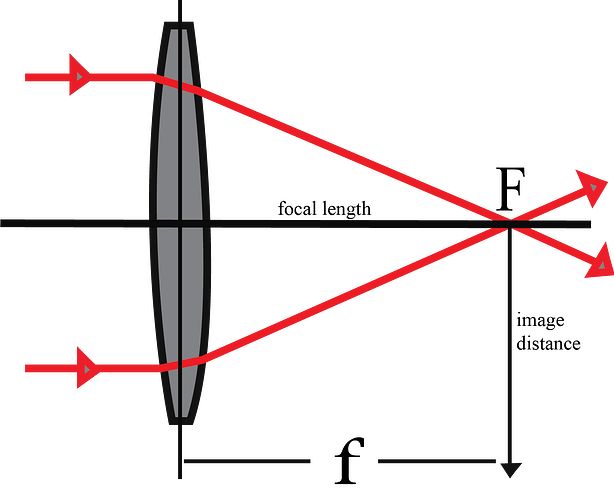

Most of the time we see the diagram of a lens with there being a finite focal point.

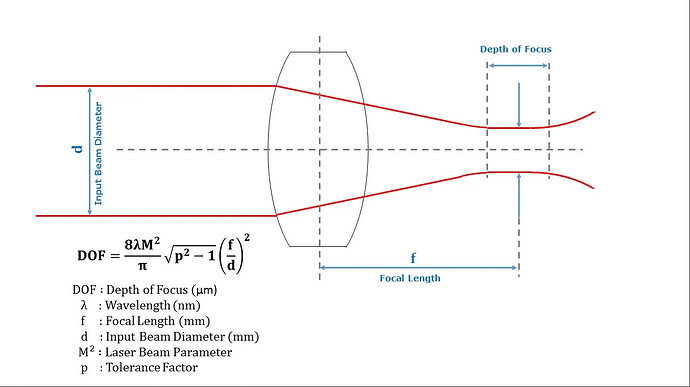

This is clear but pretty simplistic. Lenses don’t focus to infinitely small. There is an area called the depth of focus (dof). Within the dof, the beam is the same size.

Many of the on-line spot size calculators, like this one, will give you an idea of the dof.

The focal length of a short lens has a smaller spot size and smaller dof compared to a longer lens.

I have computed the dof of all of my lenses and they seem correct.

My 50.8mm (2") has a spot size of about 205 microns (0.205mm) and a dof field of about 2.75mm – the 101.6mm (4") lens has a spot size of ~410 microns and a dof of ~10.92mm.

If I were cutting 10mm, the center of the dof would be at the center of the material. That would allow the dof to encompass the materials thickness.

Many times variables are left out that makes using a calculator difficult.

Simple way to know this, I suggest, and I do, run ramp tests on all of my lenses. A ramp test will also tell you how much depth of focus you have. The ramp line will be out of focus, go into focus, stay in focus for a short distance (within dof) then go back out of focus.

Wouldn’t hurt to drop a note to the vendor and see if they can tell you any more specifics… Most of the time, they don’t know either.

This really needs to be known if you’re defocusing for some reason. You need to know how far you can move it and be out of focus.

Have fun

![]()

Thanks for that information.

The focusing block supplied with your Falcon2 40w mentions basswood because it’s meant to get you started with your supplied basswood material samples quickly. The focusing height is based on the materials thickness as noted, and the material itself is irrelevant.

When cutting the point of focus is the middle of the material. If engraving it would be the surface.

Focal point is determined by the lens. If you have a 2” lens installed then the ideal focal point is 2 inches from the bottom of the lens. You’ll have to do some research to determine what that distance is frim the tip of the cone.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.