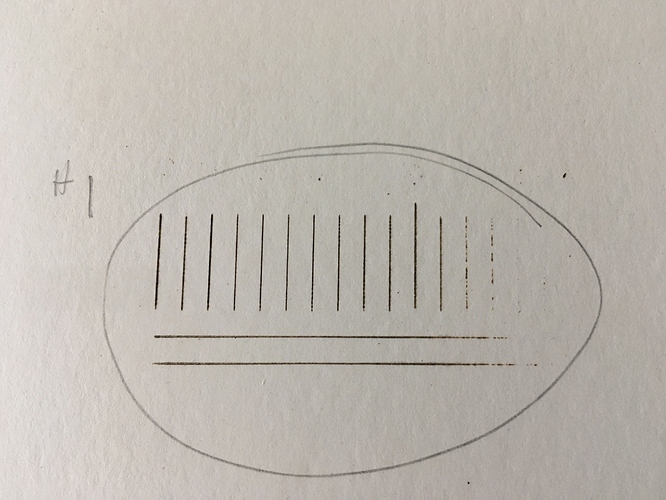

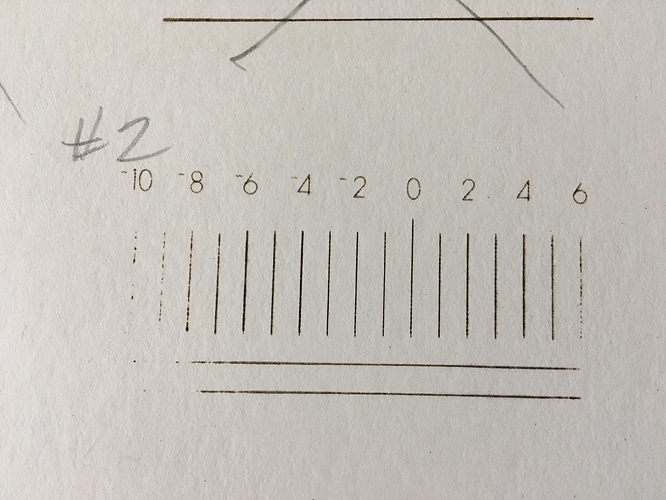

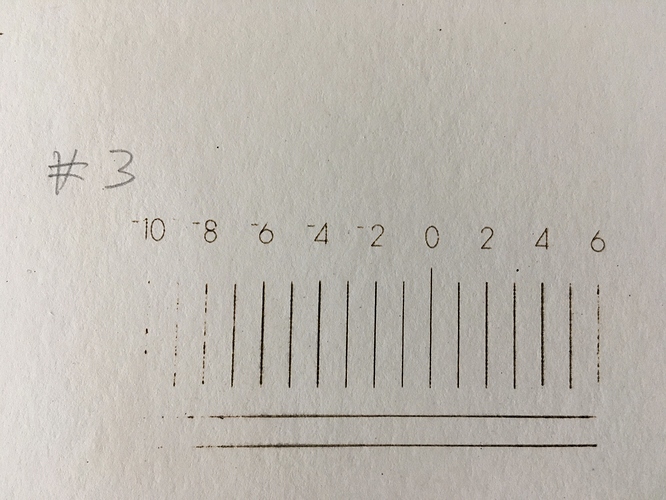

Emblaser Core. Several weeks ago I could cut black acrylic with two passes and red with 5 passes. Tried to cut black today and took 5 passes on black just to get an outline on the other side (still didn’t go through). Did 3 focus tests which are attached. First one didn’t even burn the numbers at the top, 2nd and third did not cut through the paper. It is set for -4 from previous focus test. It appears the focus test is giving different results. Test #3 has a feint mark showing on the other side but barely

White paper is very hard to mark with a diode, which is likely why the results are inconsistent. The cards provided by Darkly Labs for running the test are an off white that absorbs the light better.

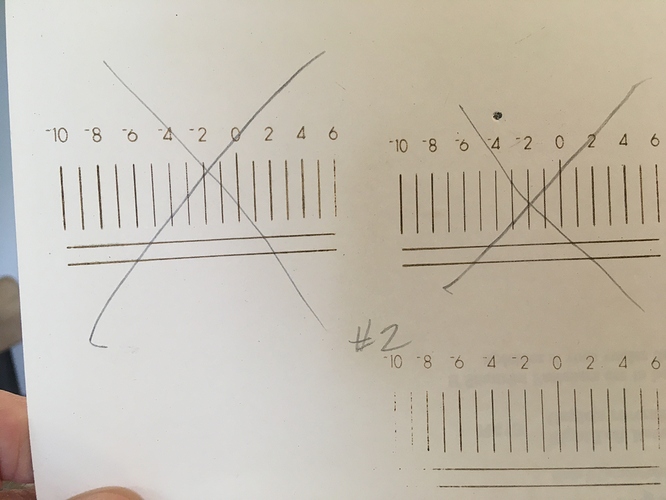

Thanks for the reply, I was using an off white file folder which is the same thickness as the cards. I’ve use this before and got readable results (see attachment with crossed out test).

Those tests were visible on the flip side. Is there any other way to set the focus, I’m sure this is why I am unable to get decent cuts on anything?Try a ramp test

I have seen the Utube demos of the ramp test but Emblaser Core does not have an adjustable bed, It is supposed to be automated with this system software. I wouldn’t know where to start. Appreciate your input.

No probs.

I don’t know your system but I understand that the ramp test simply burns a straight line up a piece of wood which is angled…

You mark the wood at the point where the line is thinnest.

You measure the distance from the thinnest point of the line to the laser head.

You then use that distance as the distance between the laser head and any work piece in the future.

At least that’s what I understand… But if you cannot raise or lower your laser head/bed I am not sure how you even achieve focus on your machine.

The laser head itself moves up and down. It is supposed to run the test (pictures above) and the thinnest line has a number next to it which is inputted into the software… which is the best focal length. The problem I’m having is I am not getting a clear test to confirm which number should be inputted into the program. I don’t know why it would change (worked ok a couple weeks ago) and now won’t cut the same material at the same settings?

Ok, my error.

Why not try a different material… Wood for example.

I know it work before but maybe the surface has been treated differently etc

Yes, I have 3mm Baltic Birch which I also tried. The writing was very faint on the job and it didn’t cut through at the end, only a faint mark on the flip side and this was another job, same settings as last week which doesn’t work. Think I’ll have to put the problem aside for a while. I have a CNC router on order so I have to get ready for that to arrive. Just frustrating that I spend 1 hour working and 4 hours trouble shooting problems. Again, thanks for the input.

If you use birch, or anything with thickness, it skews the results. When you run the focus test you just enter the calibration number at the end and that’s it. Your focus looks like it’s within 1mm of correct - when was the last time you cleaned your lens? I would also check the air nozzle to make sure it’s not impeding the beam.

I didn’t use birch, I used a thin file folder, same mm as the card from emblaser. Cleaned the lens about 2 weeks ago and have not used it much since. I disconnected the nozzle before doing the test. I’ll clean the nozzle and retry. Thanks

Cleaned the lens (looked like a smudge on it) working fine now. Thanks for the help

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.